Laying sewage is an important task. The comfort of the residents of the house directly depends on this. The first thing you have to face is the connection of sewer pipes. In some ways, this process resembles a game with a children's designer.

Content

- 1 How to connect sewer pipes: focus on the material

- 2 How to connect PVC sewer pipes and what is their advantage

- 3 Connecting plastic sewer pipes using fittings

- 4 What you need to do before starting the connection of sewer pipes

- 5 Features of arranging an external sewage system

- 6 How to connect sewer pipes: split methods

- 7 Features of one-piece joining methods

- 8 What is the most reliable option for connecting sewer pipes

How to connect sewer pipes: focus on the material

Before thinking about the method of connecting sewer pipes, it is necessary to determine the material. Today, we can talk about:

- polymer (PVC);

- cast iron;

- steel;

- asbestos-cement;

- concrete;

- ceramic;

- corrugated pipes.

The first two options are used very often, but the rest are not. ABOUT corrugated products we can only talk about the components of the sewer system of large industrial facilities or the external networks of private households.

Cast iron pipes are used when it comes to the external system. They are practically not afraid of corrosion, unlike steel, but they are too heavy for internal sewage. Especially if you do it yourself. Cast iron products are a great option for risers. Only a specialist can cope with the fastening of individual elements. Waste is constantly sticking to such pipes, because their inner side is covered with roughnesses. The risk increases significantly in the cold season. There are much fewer problems with polymer products.

How to connect PVC sewer pipes and what is their advantage

The main material used for the manufacture of sewer pipes is PVC. The peculiarity of this material is softening. When exposed to high temperatures, it becomes soft, but when cooled, it returns to its previous state. Metal pipes are practically not used now, because in their characteristics they are very much inferior to plastic ones. Before connecting sewer pipes, identify the main arguments in favor of the latter:

- no likelihood of corrosion damage. No need to spend money and time to insulate pipes that will be laid underground;

- resistance to chemicals and aggressive environments;

- high throughput due to a smooth inner surface;

- lightness of plastic pipes;

- ease of installation, the ability to build a pipeline of any design;

- long term exploitation. Such pipes can remain operational for a century.

The only drawback of PVC is the bandwidth limit, but this point can be solved by selecting pipes of larger diameter. It lends itself to the formation of elements of different configurations. The strictly defined diameter and length of each element simplifies the procedure for selecting parts.

Helpful advice! Plastic pipes can also be used for an external sewage system, but care must be taken that they do not suffer in the winter due to severe frosts. Salvation in such a situation is a soft insulation.

An important role in the process of joining home sewage pipes is played by fittings, which are connectors. They help to get a sealed structure that does not allow unpleasant odor and moisture. You will not have to think about replacing and repairing such elements for a very long time.

Connecting plastic sewer pipes using fittings

For sewer pipe connections several types of fittings are used. They vary in:

- appointment (intermediate and connecting);

- designs (tees, extension cords, couplings, turn signals);

- shape (straight, L-shaped, T-shaped).

If you use this classification during the selection of materials, then it will be much easier for you to decide on specific models and explain it to the seller.

Helpful advice! When inserting the pipe into the fitting, you must lay the rubber gasket in the joint.

What you need to do before starting the connection of sewer pipes

Sewer pipes are part of a large system. To master this task, you must initially perform the following actions:

- Creating a system drawing. Be sure to consider all the objects for which you will need to provide a connection (bath, shower, toilet).

- Determination of the joints of pipes with the main riser. Consider the connection points - this is where you will need fitting.

- It is definitely worth considering that sewer pipes for houses come in two diameters: 110 and 50 mm. The latter are ideal for showers, sinks and bathtubs, and washing machines.

When buying sewer pipes, experts do not advise taking material with a margin, because even if you do the work yourself, it is almost impossible to spoil them.

The turn signal fitting connects the siphon (hose extending from the plumbing fixture) and a metal or PVC sewer pipe. Some masters do not use this connecting element, but this is fraught with a violation of tightness. It is unlikely that you want a pool in your bathroom or kitchen to constantly appear as a result of a leak.

In order for the sewer system to serve for a long time, pay attention to such points:

- the need to ensure a certain size of the slope of the pipes. This helps to drain fluid as quickly as possible. Calculate the slope so that the decrease does not exceed 2-3 cm per meter of pipe;

- do-it-yourself installation of the system is necessary from the devices in the direction of the main riser. The flow of water will not be hindered by joints.

Features of arranging an external sewage system

Domestic or in-house sewage requires the use of fittings. Another case is the external system. It is laid in the local area. A prerequisite is the arrangement of wells. Such facilities allow you to easily clean the sewer. Having learned how sewer pipes are connected, it becomes obvious that the external system involves the use of larger pipes.

Helpful advice! Be sure to consider the fact that when inserting a sewer pipe into the outside, it is necessary to increase the size of the latter. It is better to take a model with a “margin” so that when it becomes necessary to connect new plumbing, you do not have to change the entire system.

After the preparatory work, you can get down to business. Types of sewer pipes and connections foresee two options for performing work: detachable and one-piece connections.

How to connect sewer pipes: split methods

Plug-in connections can be flanged or female. For PVC pipes, the first method is better. Do-it-yourself tightness helps to achieve the use of cast iron fasteners and rubber gaskets. The work consists of the following stages:

- pipe cutting. What matters is a perfectly even cut. A chamfer is not done;

- putting a loose flange on a slice;

- rubber pad insert. It should protrude 10 cm from the cut;

- imposing a flange on the gasket and connecting with the mating flanges;

- fastening bolts.

Couplings are used during repairs or during installation of pressureless and pressure systems. For high-quality operation of the system it is necessary:

- the ends of the elements to be connected are cut at a right angle;

- apply the coupling to the place of alignment in such a way that its central part is at the junction of the pipes;

- marks are made on the pipes corresponding to the position of the coupling;

- the inside of the coupling and the ends of the pipes are treated with special grease;

- one of the pipes is inserted into the coupling to the limit;

- pipes must be installed so that the axis is unified;

- the coupling is pushed onto the second pipe until the mark is made earlier.

This method allows you to disassemble the pipeline if necessary, but when installing it, you should pay attention to the tightness of the connection.

Features of one-piece joining methods

One-piece connections are divided according to the method used:

- "Into the bell". For its implementation, it is necessary to connect the bell with a rubber ring and the smooth end of the pipe, having previously cleaned and degreased the surface. Be sure to chamfer the smooth end. Carefully lubricate the connecting surfaces with silicone grease and make sure that their longitudinal axis coincides. The smooth end must be inserted into the socket. Do not push the pipe past the mounting mark;

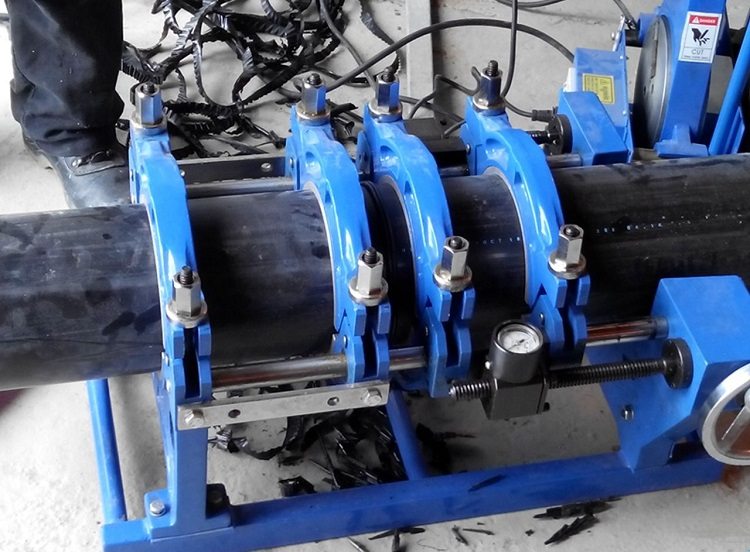

- by welding: in the socket and butt. When using the first method, the inner part of the bell of one pipe and the outer surface of the smooth end of the second are melted using a welding machine. When butt welding, it is necessary to melt the ends that will connect and directly the joint itself. For this, moderate pressure is used;

- by gluing. You will need a special glue that lubricates the connecting ends. The choice of glue depends on the material of the pipes. Metal and plastic samples require BF-2, polymer and metal - epoxy, rubber and metal - 88N.

What is the most reliable option for connecting sewer pipes

The simplest type of connection is “into the socket”. It can be performed not even by a specialist. The main guarantee of tightness is the rubber ring of the bell. The bell is necessarily directed in the opposite direction from where the water is directed.

Helpful advice! Instead of grease for pipes, if it is not at hand, it is quite possible to use a detergent or liquid soap.

Welding is a very complicated method. You will need special equipment, but the reliability of this method is very high.

Welding is a reliable method, but it requires the use of special equipment and skills to work with it.

The mutual penetration of the adhesive at the molecular level is the key to high bond strength when using glue. Be sure to clean any contaminants that you plan to glue. They also need to be degreased. In this case, you need to act very quickly.

Fittings are secured with o-rings. Installation is carried out independently. This method is suitable for small diameter pipes. Fix the pipes in such a way that there is constant access to the joints and you can get rid of blockages. Before connecting PVC sewer pipes, special preparation is not required, unlike metal models.

Tips will help ensure the tightness of the system and save you from the need to constantly carry out repairs. Poor connection can cause unpleasant surprises associated with leaks or breakouts.