Plastic pipes are unique products that consist of three main layers: the inner polymer, the intermediate metal and the outer polymer. During the installation of metal-plastic pipelines, it is very important to choose and install the fasteners correctly. As a rule, such pipes are attached to work surfaces with the help of special devices - clips.

With the help of plastic clips, various types of pipes are fixed, this type of fixation is most common during the installation of metal-plastic systems

Content

Advantages and disadvantages of metal-plastic pipelines

Metal-plastic communications are very popular today. This is due to the fact that their installation is simple and does not require special building skills. Thus, even a novice can lay a metal-plastic pipeline.

Such products combine the positive qualities of both metal and polymer products. Consider the main advantages of metal-plastic communications:

- easy installation;

- high speed communication;

- high rate of thermal stability (maximum operating temperature for such products reaches 100 ° C);

- affordable cost;

- high strength characteristics (due to the aluminum layer, which is an intermediate layer of the pipe);

- high coefficient of ring stiffness;

- resistance to harmful corrosive effects;

- resistance to active chemical compounds;

- the smoothness of the inner walls, due to which high throughput indicators in the system are achieved, and the accumulation of salt deposits is significantly slowed down;

- low coefficient of thermal conductivity;

- possibility of repair;

- long operational period;

- attractive appearance.

Helpful information! Good ductility of metal-plastic pipes, allows them to bend during installation, thereby simplifying the work. For fixing communications of this type, special fixing elements - clips are most suitable.

Like any other product, metal-plastic parts have their drawbacks. The main disadvantage of such products is that the metal and plastic, which are part of them, have different indicators of thermal expansion. Such a disadvantage can lead to the fact that as a result of the temperature difference, the separation of the components will occur and a leak will form. In order to exclude such a possibility, it is recommended to take care of the stock at the joints of individual structural elements during the laying of the metal-plastic structure.

Overview of tools and materials required for pipe fasteners

In order to organize the fastening of the metal-plastic pipeline to the wall, it is necessary to correctly select the components. During the selection of fasteners, it is necessary to take into account the physical and technical characteristics of the pipeline, namely:

- length of communication;

- pipeline cross section indicator;

- mass of the highway.

The correct selection of clips allows you to proportionally distribute the mass of communication on these elements. This ensures reliable design and eliminates unforeseen emergency situations.

Consider the list of tools and devices that are used to fix the metal-plastic structure to the working surface:

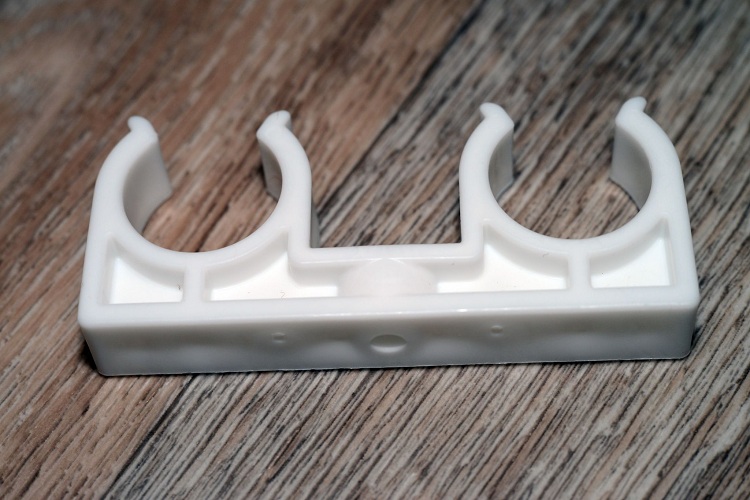

Clips. These are fixing elements that are used in the installation of metal-plastic and plastic pipelines. In rare cases, clips for a metal-plastic pipe are not made of a polymeric material. The main areas where clips are used are water supply networks and heat pipes. Clips for pipes are divided into:

- double;

- single.

The clips are single and double, both options are suitable for fastening pipes on the walls and on the floor

When installing the pipeline using polymer clips, it is necessary to observe the distance between them, and also not to make a mistake with the diameter of the ring (the pipe is fixed in the retainer ring). The clips are great for communications, the cross-sectional index of which does not exceed 50 mm.

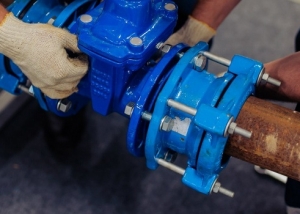

Clamps. These products are used to fasten various elements of the pipeline structure to the wall. There is one important rule that you need to remember when choosing pipe clamps: the internal indicator of the cross-section of the clamp should be greater than the external cross-section of the communication. Many clamps are equipped with special rubber pads that provide more reliable grip with the pipe. The popularity of clamps is due to the fact that they can be mounted on different pipe diameters (due to the possibility of regulation). All clamps are divided into two main groups according to the material of manufacture:

- metal;

- polymer.

Note! Experts recommend buying clamps made of the same material as the pipe structure being laid.

All clamps are divided into four varieties for their intended purpose:

- fixing;

- supporting;

- guides;

- protective.

Brackets. As a rule, such fixing elements are used when laying steel communications. Using brackets allows you to position and fix the pipe at a small distance from the working surface.

In addition, the pipeline can be fixed not only to the wall, but also to the ceiling. In this case, it is necessary to purchase special bolts, which are called anchor bolts.

Basic rules for fixing pipes to the wall

Correct installation of any pipeline design should be carried out taking into account building codes and rules prescribed in the relevant regulatory documentation. In addition, there are a number of rules that will help to fasten a metal-plastic pipe to a wall using clips:

- fasteners for metal-plastic pipes are made of polymer materials and are fixed on the wall using self-tapping screws. Experts recommend performing the work in sequence: first, the holder is fixed and only then the pipe snaps into the polymer end of the device;

- during the installation of metal-plastic communication, its individual segments, one way or another, will have to be bent at certain angles. Bending of metal-plastic products allows not only to reduce the time of installation of communication, but also to preserve its integrity. In places of bends, as a rule, pipes are not fixed to the working surface;

- as mentioned above, metal-plastic pipelines consist of two main components, the coefficient of thermal expansion of which is not the same. To balance this process, it is recommended to use special compensating loops during the installation of the metal-plastic pipeline.Such loops allow you to save free space between the pipe and the locking element.

When installing communication, you need to remember that in places of pipe bends, clips are not installed

The above recommendations will allow you to mount metal-plastic communication, avoiding common mistakes that can lead to system failures in the future.

Algorithm for mounting and fastening the pipeline

Fastening for plastic pipes is quite simple. In order to perform such work, it is not necessary to have building knowledge and skills, however, all manipulations must be carried out carefully, without rushing anywhere. Let's consider what tools and materials will be needed for fastening metal-plastic pipes:

- clips;

- wood screws.

A step-by-step algorithm for mounting and organizing the fastening for a plastic pipe looks like this:

- First of all, it is necessary to straighten the pipe. To do this, you can simply step on one of its ends, after which the pipe straightens on the floor manually.

- You will need to cut the pipe to the required size. The dimensions of the individual elements of the pipeline communication are calculated before installation. Pipe cutting is carried out by means of special scissors adapted for work on metal plastic.

- After cutting the pipes, care must be taken to ensure that their edges do not contain any burrs or other defects, dust or dirt. The intermediate layer of aluminum foil should not interfere with the connection of the pipes. To eliminate defects, a special device is used - a calibrator.

- At the fourth stage, the fitting is installed.

- Then (if necessary) the pipes are bent at the desired angle. Bending can be carried out using a special pipe bending device, which can be purchased at almost any hardware store.

- At the last stage, the pipe is directly attached to the working surface. It is worth remembering one important rule: the higher the temperature of the working medium in communication, the smaller the distance should be between the clamps. The distance between the clips is calculated in advance, after which the necessary markings are made on the wall, which will simplify installation in the future. The fastening of metal-plastic pipes to the wall must be performed so that the pipe is located under the minimum slope, which is made in the direction of movement of the working medium. The clips are fixed to the wall with screws or, in some cases, dowels.

If the pipes of cold and hot water are located nearby, it is better to use double clips and save the time allotted for installation

Note! Experts recommend that before self-installation of the pipeline to perform all necessary calculations and draw up a diagram of future work. The scheme should take into account the following points: the dimensions of individual communication elements, production measurements, as well as the points at which the connecting elements (fittings) will be located.

For surfaces of different materials, there are individual options for fixing the clips to the wall:

- installation of clamps on a concrete wall is carried out using self-tapping screws and dowels, as well as a perforator (for making holes);

- on a wooden work surface, the clamps are installed using screws and a screwdriver.

That clip is ideal for fixing a plastic pipe. Such devices make it possible to fix metal-plastic and polymer pipelines, which include a large number of bends and branches.