Installation of a heating system in a private house or apartment involves the selection of materials for optimal operation of the pipeline. Exposure to corrosion and high cost make consumers gradually abandon metal structures. Thanks to the excellent technical characteristics, polyethylene pipes for heating have become an excellent replacement for many similar metal and plastic products.

Content

Features of pipes for heating from cross-linked polyethylene

It is known that polyethylene is a rather fusible material, in the usual state it begins to soften already at a temperature of 40 degrees. Conventional polyethylene pipes are not suitable for heating. But modern manufacturers managed to create a fundamentally new type of polyethylene - cross-linked, the technical characteristics of which have nothing to do with ordinary. Molecular compounds in such a material provide maximum strength to the finished product. HDPE pipes are marked PEX and are widely used in heating systems.

It is worth considering the fact that polyethylene pipes do not tolerate exposure to sunlight. With prolonged heating of the pipe surface with ultraviolet rays, cross-linked polyethylene begins to decompose, making the water toxic. To reduce the effect of sunlight on plastic products, it is recommended to varnish them.

The soft walls of HDPE structures attract rodents and insects. It happens that pests eat holes in pipes, due to which water leaks occur. Therefore, cross-linked polyethylene pipes are not recommended to be laid in the ground without protection.

Crosslinked polyethylene is destroyed by ultraviolet radiation, so pipes from it are mainly used for laying internal networks

Cross-linked polyethylene heating pipes: characteristics

In addition to polyethylene, from a number of pipes made of polymeric materials in arrangement of heating systems metal-plastic pipes are often used. Products made of metal-plastic have some functional disadvantages, for example, insufficient degree of flexibility. Therefore, they are replaced by pipes made of cross-linked polyethylene, which practically do not have significant shortcomings. From other products intended for the heating pipeline, they are distinguished by such advantages:

- Pipes for heating from cross-linked polyethylene are very flexible, they tend to return to their original state if a wall surface deforms. Over time, the pipes do not lose their ductility, creases and cracks do not appear on the bends;

- cross-linked polyethylene does not lose its positive qualities, even if the temperature in the system exceeds 95 degrees. Pipe deformation does not occur even in emergency situations, when the temperature in the system reaches 200 degrees;

- polyethylene pipes are resistant not only to high temperatures, but also to aggressive substances (solvents, gasoline, toluene, antifreeze), pressure drops.Exposure to mineral oils and fatty substances causes only the swelling of the surface of the polyethylene, but not destruction;

- during combustion and melting, HDPE pipes do not emit vapors hazardous to humans. Cross-linked polyethylene begins to melt at 400 degrees.

Important! HDPE pipes for heating do not tolerate contact with strong oxidizing agents, such as nitric acid.

PEX pipes tolerate high temperatures and pressures well, so they are almost indispensable in underfloor heating systems

Cross-linked polyethylene pipes are used not only for heating. Such constructions are widely used in laying warm floors, as well as hot and cold water supply systems.

How are pipes made from cross-linked polyethylene?

Crosslinking of polyethylene is carried out in several known ways:

- peroxide crosslinking technology. In the process of heating polyethylene, peroxides are introduced into the composition.

- silane method. Polyethylene is treated with a liquid containing catalysts and directly silane. The level of crosslinking of polyethylene molecules was thus increased by almost 70%.

- electronic stitching method. A strong bond of polyethylene molecules in the crystal lattice is achieved by the so-called electron bombardment. A reaction occurs with the release of free vapors that are perfectly bonded to each other.

Also, the production of crosslinked HDPE was carried out using nitrogen treatment, but the technical characteristics of such products were not high enough. Now this method is not used in the manufacture of PE pipes.

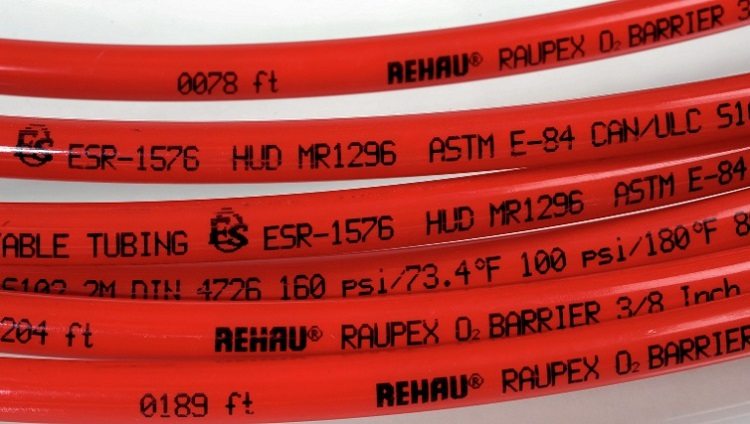

The method of production of a particular product can be found by paying attention to the Latin letters in the marking. These can be models PE-Xa, PE-Xb, PE-Xc.

The method of production of pipes is indicated on the outside of the pipe along with other characteristics of the product

Installation of cross-linked polyethylene heating pipes

For the installation of DIY heating systems, pipes made of cross-linked polyethylene are ideal. Fitting and other components for HDPE pipes have a fairly low cost, and specialized equipment will not be needed to carry out the work. When installing pipes made of cross-linked polyethylene, it is required to make a minimum number of connections, which affects the amount of time spent on work. However, the joints are very strong and airtight.

Helpful advice! Any installation work should begin with the creation of a detailed home heating scheme. If it is planned to bring underfloor heating systems to the main heating main, this also must be taken into account in the plan.

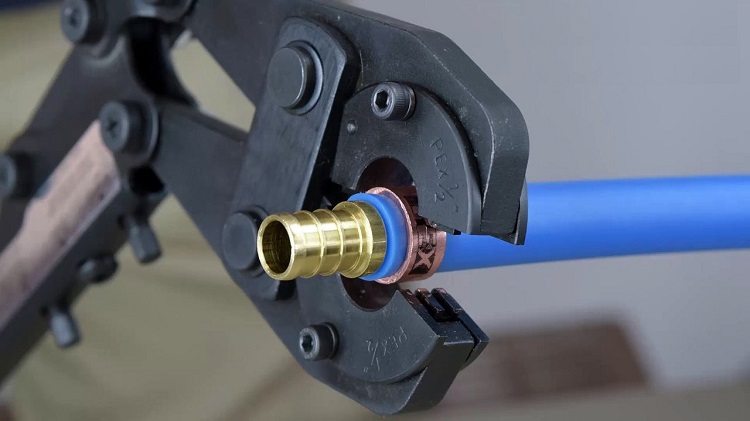

Connections of heating pipes made of cross-linked polyethylene are carried out using press fittings. Of the installation tools, you only need a vice for pressing in and various nozzles for them, as well as tools for expanding the edge of the pipe.

First of all, a sufficient amount of a polyethylene pipe is cut off. It is better to cut HDPE with a specially designed tool - a pipe cutter, but you can also use an ordinary hacksaw, a file or construction scissors.

Installation of HDPE pipes using press fittings is carried out in the following order:

- a clamping sleeve is put on the pipe;

- at the end of the pipe segment, an expander is inserted up to the stop, corresponding in size to the diameter of the pipe. The handles of the expander are reduced to the stop, remaining in this position for 5-10 seconds;

- the pipe is inserted into the fitting of the fitting;

- the structure is pressed with a vice or special pliers.

There are no difficulties in installing pipes made of cross-linked polyethylene. Those who do this kind of work for the first time may have questions regarding the degree of force that needs to be applied to press the joint in. This moment needs to be felt, having trained on spare pipe sections.

The main principles of installing HDPE pipes

Heating systems laid with pipes made of cross-linked polyethylene do not differ in design from standard ones. All heaters are connected in the usual way. Some features are in the order of installation of the PND pipeline itself:

- with a high temperature difference between the street and the house, installation is undesirable to proceed immediately after the delivery of pipes. Pipes need to be given at least a few hours to warm up.

- It is undesirable to lay a pipe from cross-linked polyethylene in an open way. These pipes are quite sensitive to mechanical damage, so it is better to hide them in the ceilings of walls and floors.

- Crosslinked polyethylene has a high coefficient of linear expansion. Therefore, niches for the pipeline should have a slightly larger size than the diameter of the pipe. HDPE pipes are strictly forbidden to fill with a continuous layer of concrete or screed.

- The mechanical fittings used during installation should not be hidden in the ceiling. They should be provided with free access.

Important! If the installation of a heating pipe made of cross-linked polyethylene is carried out by welding, it is necessary to carefully monitor the temperature of the soldering iron. The polyethylene is fusible, so because of the exposure to the soldering iron for more than 10 seconds, the pipe may simply burn out.

Cross-linked polyethylene pipes are an excellent option for home heating systems. With proper installation and operation, they will serve for a long time and efficiently. Their characteristics allow the system to work flawlessly for five decades.