The most reliable detachable pipe connection is obtained using threaded couplings and fittings. There are a lot of species on the market threading tool. And the choice of a suitable sample of a device such as a screwdriver can be fraught with complexity. Moreover, this question is capable of confusing even a highly qualified locksmith. Meanwhile, the screw hob is very convenient to use and with its help it is possible to cut into the required part of the external thread.

Content

What is a screwdriver

More recently, only a die (another name - lerka) was used to cut external thread on metal. This is a rounded part made of tool steel characterized by high strength. The thread inside the die is cut by the cutters. On the outer perimeter of this part are recesses for the holder. When studying its design, the question may naturally arise: is it really necessary to make the entire case from expensive tool steel, and is it possible to reduce the cost without compromising the functionality?

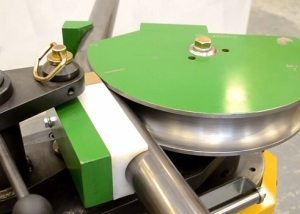

This idea was embodied in the development of the pipe plug. This tool retained all the operational qualities of the die, but it became much more affordable. From kerkl klupp borrowed only high-strength cutters that are mounted on an inexpensive holder. A handle is inserted into it with which rotational movements are performed. Since the cutters are interchangeable, they can be changed easily in the holder.

Compared to a traditional tool, using a screwdriver is much more convenient and faster. With its help, the thread is cut in places to which the die would not reach. By the way, cutters for pipe dies can be purchased separately. Their cost is relatively low. Therefore, if threading is part of your professional responsibilities, you can buy cutters with a margin. But there is one caveat. Having made the decision to purchase a set of spare cutters for the screwdriver, opt for products manufactured by the same company that the threading tool itself produced.

The reason for this recommendation is that on holders from different manufacturers, attachments for cutters may differ. You simply cannot insert the cutters into the holder! Therefore, if in doubt about the successful search for incisors of the same company, go to the store, grabbing your holder. Then you are sure to find the right model for this metal cutting tool.

Varieties

For the classification of klupp used, mainly two criteria - ease of use and cost.

Simple manual screwdriver. Such a tool resembles a good old die in the holder of the most primitive design. The frame is a circular guide with clamps for cutters and 2 handles, with which the artist rotates the die.

On a note! The set of the simplest and cheapest klupp do not even include pens. The gas key of the third or fourth number successfully copes with the performance of their functions.

Manual screwdriver equipped with ratchet. The design was complicated slightly: the ratchet inserted into the frame provides an opportunity to do without intercepting handles. The contractor simply makes a single handle reciprocating motion, reminiscent of the procedure for pumping water with a pump.

Electric pipe clamp A similar tool is included in the category of professional equipment for threading. The device is equipped with an electric motor. This design solution allows you to effortlessly cut threads on pipes of various diameters.

Device. How to work with an electric switch

This device is powered from the mains and has an impressive coefficient of transmission of force to the cutters. This is realized due to the fact that a multi-axis gearbox is included in the design of the electric switch. For example, in this component of the Gerat model there are seven shafts with gears that have been subjected to microwave hardening. The gear housing is made of aluminum alloy. Execution of the closed type, additional lubrication is not required.

The thread-cutting part is inserted into the seat by an external octahedron. Installation / removal of heads is done with preliminary disconnection from the power supply.

The sequence of steps and the features of threading with an electric screwdriver look like this:

- fix this device with a fixing clamp parallel to the intended treatment of the pipe section. In this case, the axis of the head should coincide with the axis of the workpiece. Also control the distance between the tool body and the lock. It should be sufficient to cut the thread of the required length;

- check the direction of rotation of the die;

- apply thread-cutting oil to the area. Maintain a sufficient amount all the time to reduce the heating of the cutters and the friction load;

- to ensure a uniform cutter entry, prepare the pipe end - expand it and remove the chamfer. If the cut is not at right angles, the thread will not cut correctly;

- Pay special attention to how the first two turns go, then threading will be performed automatically. Rothenberger electric screwdriver gives a forward speed of 15-20 revolutions per minute. When reversing the head rotates more intensively - 60 rpm;

- when working with old pipes, hold them with a gas wrench, since a lot of force is applied to the cutting edges;

- a standard-sized thread is obtained by combining the output edge of the cutting comb of the head with the edge of the pipe;

- before the next operation, clean the comb from old oil and chips;

- work with the Rothenberger screwdriver from a stable, comfortable position. The space should be sufficient to hold the power tool steady and steady.

Working with an electric switch has its own characteristics and requires strict adherence to the rules.

On a note! When it is necessary to update the old thread in difficult conditions (for example, if the thread is located near the walls), the forward stroke is minimal. In this case, in order to achieve the desired result, you can reverse the orientation of the comb combs.

Advantages and disadvantages of the tool. Failure reasons

Turning to the consideration of the pros and cons of the electric switch, in the first place, it should be noted that. Its power is relatively small. Nevertheless, it is enough for this unit to thread even on fairly strong material. Thus, expensive energy is not consumed.

In addition, a professional electric screwdriver for threading has the following advantages:

- reliable electric drive;

- high speed threading;

- effective chip removal;

- the ability to adjust the main parameters;

- ease of setup and ease of operation;

- light weight and ergonomic shape.

There are also disadvantages. The main ones are as follows:

- unlike a hand tool, you cannot work with an electric screwdriver anywhere. It requires power supply;

- the unit under consideration is more voluminous. Therefore, it weighs more and takes up more space;

- work in hard-to-reach places is impossible due to the considerable dimensions of the electric switch.

The causes of failures can be very different. However, according to data from manufacturers, the following prevail:

- worn electric brushes;

- the thread-cutting edges of the comb are worn out;

- non-original thread-cutting head was used;

- poor quality or lack of thread-cutting oil;

- damaged power supply circuit (fuses, cord).

Leading manufacturers and selection rules

In the segment of electric switches of the modern market there is intense competition. And if, for this reason, manufacturers must invest significant amounts of money in the modernization of production lines, then consumers, on the contrary, get better products for the same money. However, preference should be given to electrical switchboards from the following companies:

- REMS (Germany). Amigo Rems models are presented in our market, as a rule, in a branded case-case made of durable steel. In addition to the tool itself, the kit includes interchangeable heads for any - right and left - threads.

- GERAT (Germany). The scope of supply for the electrical screwdriver from this manufacturer includes interchangeable heads, a clamp, and an oiler.

- RIDGID (USA). This company also offers threading tools in sets. Their price depends on the configuration.

- ROTHENBERG (Germany). The most popular electric screwdriver for threading from this manufacturer model Supertronic. In the plastic case, besides the device itself, you will find interchangeable heads, a clamp and a power adapter.

In general, when buying this tool, you need to be guided by the “price / quality” criterion and take into account the following recommendations:

- stop your choice with a klupp with replaceable cutters.

- consider the diameter of the pipe to be processed;

- find out the material for making the cutters. Long-life parts are made of alloy steel, while low-cost models are equipped with cutters from quickly erasing cheap metal.

Important! Replaceable cutters make it possible to quickly replace a dull part with a new one.

And it should be remembered that only correct operation will allow the tool to last as long as possible. Therefore, before you buy a thread-cutting kit, read the rules for working with an electric screwdriver and compare them with the expected conditions for threading. Having made the right choice, you can use this device for a long time.