A hydraulic pipe bender is a device that is used in the installation of piping systems, supporting and decorative structures of rolled pipe. It bends the pipes at different angles with the help of a drive, which greatly facilitates the work on the manufacture of bent elements. Such devices can bend parts of various formats, including profile blanks.

Content

Where is a hydraulic pipe bender used?

This kind of pipe bender has a wide scope. However, it is most popular during repair work. When installing the pipeline, it is an indispensable thing, as it performs pipe bending at different angles and due to this, the necessary configurations are obtained.

Bending pipes on such a device allows you to get reliable bends and not spoil the part (for example, if you try to bend the pipe manually, it can simply burst or deform so that its further use in the system will be impossible).

When installing a pipeline communication from metal, this device allows you to get fewer joints and joints, which, as a rule, are considered problem areas and may leak in the future. In addition, welding work to connect straight segments with turning parts requires special equipment and skills. Pipe bending devices are used in the installation of the following systems:

- heating;

- air conditioning;

- water pipes;

- gas pipelines.

In addition, the hydraulic apparatus is used to obtain various frame structures, fences and other structures for various purposes and scale.

Device and principle of operation

The main distinguishing feature of such devices is the presence of a hydraulic cylinder. It is the part that affects the pipe when it is flexible. This allows you to process products without any effort. The pressure exerted by hydraulics on the pipe is 10–12 tons. In addition, each hydraulic device incorporates special support elements - shoes. Their size is selected according to the diameter of the bent products. The function of the support shoes is the reliable fixation of the workpieces during the bending process.

Note! The dimensions of the pipes that will bend on the pipe bender are selected based on its power. The optimal parameter for pipes is a diameter of 10 to 15 cm.

The bending itself goes like this: the hydraulic cylinder shifts the support shoes that fix the part, resulting in an even bend in its center. Hydraulic devices are often equipped with special marks with the designation of angles, which makes it much easier to navigate in the work process and to implement very accurate pipe bends.

Types of hydraulic pipe benders

First of all, pipe benders with a hydraulic drive are divided into two main types:

- hand held;

- with electric drive.

Manual hydraulic pipe bender involves the use of a single-stage handle. It has only one valve, which is responsible for regulating the hydraulic cylinder. The electro-hydraulic pipe bender, unlike the manual one, is equipped with a two-stage handle that regulates the working position of the cylinder. The manual type is quite simple and, if necessary, it can be done with your own hands. Electro-hydraulic pipe bender allows you to perform large volumes of work and, as a rule, is used in various industries.

Most models of hydraulic pipe benders have restrictions on the angle of bending: it is 90 °. However, in order to perform bends at an angle higher than the straight line, there are additional elements that can be easily purchased at hardware stores.

Note! A hydraulic pipe bender for bending pipes (both manual and electric) is a fairly productive and convenient device that allows for very precise bending of pipes, including thin-walled ones.

However, for the workflow on manual models, it is still worthwhile to make certain efforts - to pump the handle of the hydromechanism. The electro-hydraulic pipe bender is more advanced in terms of work, but its price is an order of magnitude higher than the manual type. Also, do not forget that when operating an electro-hydraulic pipe bender, you will have to pay extra for energy consumption.

The hydraulic pipe bender can be equipped with an electric drive, for the operation of such a device you need to have a constant power source

Key benefits of hydraulic hand benders

A hydraulic-type pipe bender bends pipes due to the high pressure applied to one (hand-held devices) or several points (electric models). The most common type of device is a hydraulic crossbow bender.

Hydraulic handheld devices have many advantages over other varieties. Their main advantages include:

- compactness;

- cheapness;

- reliability;

- ease of use;

- mobility;

- accuracy;

- high bending speed;

- lack of additional energy costs.

Hydraulic-driven pipe benders, unlike conventional hand-held devices, have higher efficiency and can perform quite large volumes of work. In addition, they are not stationary, which allows you to operate them in the right place. Due to the fact that the design of such a device is much simpler than that of electrical counterparts, they break much less frequently. This is also a huge plus.

Hydraulic grease

Each fixture, which includes moving parts, needs lubrication. To implement the working process of a hydraulic pipe bender, you need a special oil. Such an oil should have the following characteristics:

- Oil purity at temperature differences. It should have sufficient transparency and not have a tendency to precipitate at low and high temperatures.

- Hydrolytic stability. If water gets into the hydraulic pipe bender, the oil must ensure the operability of the mechanism and protect it from rust.

- Filtrational qualities. The oil should not have a too thick consistency to pass freely through the cleaning filters.

Compliance with the above requirements allows you to protect hydraulic equipment and extend its life. Hydraulic lubrication is a necessary part of any moving mechanism. Without it, the operation of such equipment is simply impossible. In addition to the protective properties, the lubricant can reduce physical activity when bending pipes.

Hydraulic Pipe Bender Tips

One of the most common problems encountered during the operation of hydraulic equipment is air entering the system. At the same time, the design develops a decrease in the developed force, as a result of which the bender handle begins to spring.

Repair of hydraulic pipe benders in this case is quite simple. To fix this problem, it is advised to screw the pipe bender screw all the way and remove the axis that joins the handle with the plunger. Then you need to remove the plunger and pour oil into a special hole in the sleeve. Next, the design is assembled back and the handle is pumped. For pumping enough 10 movements.

A fairly common problem when using hydraulic pipe benders is the static nature of the rod element. If it does not move during the operation of the device, then you need to check whether the suction check valve is working. Repair is recommended as follows: tighten the screw and raise the handle of the device until it stops. Next you need to hit her so that she lowered. If necessary, you can repeat this procedure several times.

Important! Hydraulic pipe benders need periodic checks. This rule especially applies to the electrical type of devices whose parts wear out over time. Worn parts must be periodically replaced with new ones. If you do not perform repairs on time, then this is fraught with big problems.

And finally, very often there are breakdowns of the electric drive in electric pipe benders. In this case, it is recommended to call a master who understands such issues and will be able to make high-quality and competent repair of the bending device.

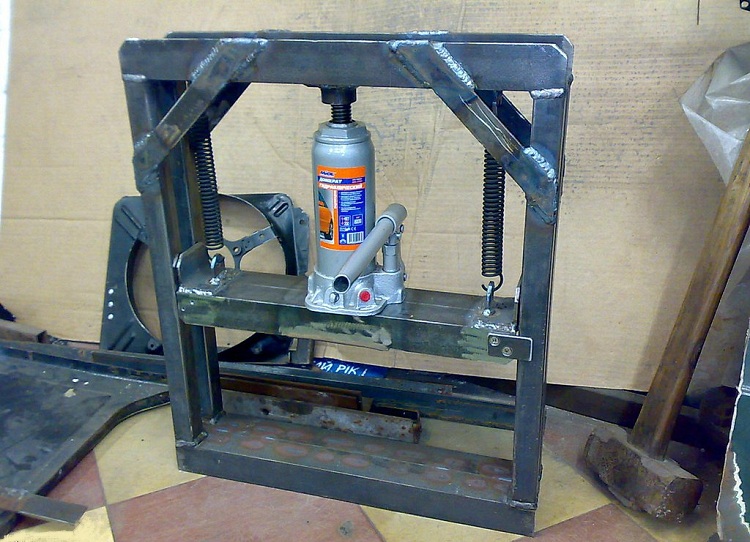

DIY hydraulic pipe bender assembly

When choosing a material for a pipe bender, it is necessary to be guided by two important characteristics: reliability, practicality. It is also worth considering that the pipe benders that are used in enterprises are usually made of thin-walled metal and have little resistance to mechanical stress. You can assemble a hydraulic pipe bender with your own hands and with a more reliable support frame.

In order to make a supporting frame for a pipe bending device, experts recommend the use of steel sheets with a thickness of 3 mm or more. To such a sheet you need to weld corners, the dimensions of which depend on the characteristics of the bent pipes. For the supporting elements of the rollers, the channel is perfect.

DIY assembly of a pipe bender:

- the mass of the structure directly depends on the strength indicators. Each device has its own such parameter. It should be taken into account if you decide to assemble a mobile device, but for stationary machines this is not so important. The material for a manual hydraulic pipe bender should be strong enough and not very heavy;

- In order to increase the reliability of the structure, it is best to connect its individual elements by welding. Such a non-separable system is much more reliable than a mechanically fastened device.

Important! To assemble a hydraulic pipe bender with your own hands, you will definitely need welding equipment, a drill and a grinder. In addition, experts recommend that before starting the assembly, make a plan and purchase all the necessary materials to avoid unplanned situations.

In what order do you need to assemble the pipe bending machine:

- At the first stage, it is necessary, in accordance with a previously completed drawing, to make a support frame for the pipe bender and weld the support posts.

- Next, using a drill, you need to make holes in the channels.

- In the third stage, the channel is attached to the support posts.

- At the end you need to install the jack.

Supporting elements are recommended to be ordered separately, since it is quite problematic to make them yourself.The rest of the assembly of such a device is not difficult.