Klupp manual for threading - a mechanism that allows you to create an external thread on pipes, bolts, studs, bends, barrels. The device is also used to regenerate an already finished but slightly worn cut. The tool consists of a holder and cutters. The latter are made of high-strength metal, which guarantees the durability of the entire device and the creation of high-quality threads. There are two types of manual thread-cutting screw die: the first type is capable of cutting threads from 0.5 ″ to 1 1/4 ″ in diameter, and the second one in 1 1/2 ″ and 2 ″.

Content

Tool Overview

Thread cutting is carried out by all known tools - taps, screwdrivers, handles and dies (sweeps).

Runners are used to provide screw threading to bolts. They can be imagined as a hardened steel nut, the cutting edges of which form special slots.

Lerka is a set of thread-cutting nests assembled in one plate. The holes in the handle can cut only one thread size.

The klupp design is reminiscent of a lerk and die. Only the cost of this device is much less than one sweep. The device is used if it is necessary to change the pipe or its section, attach additional connections, replace the system’s branch, redirect the pipes.

Modern tools have various modifications to simplify the work. So, today's models of screwdrivers are equipped with a single handle. The usual handle, consisting of two rods, is not always convenient to use. In domestic use, a manual screw ratchet is common. Its design allows you to continue working after a turn, without removing the handle from the holder.

Modern options of these tools are also additional dies for working in hard-to-reach places, improved geometry of the cutters, which guarantees a good chip flow and easy entry into the material. Precise centering of the thread is ensured by an elongated guide.

Hand tools are not inferior to electric ones in terms of reliability and accuracy, while having less weight and size. Basically, the mechanism is used to create cuts on water, heating and gas pipes.

Helpful advice! To prevent wear of the cutters, a cutting fluid is recommended.

Types and designs of manual screwdrivers

Each type of tool has its own characteristics and differences in design.

1. Squinting kluppa

The mechanical threading on the rods and bolts is carried out using an oblique screw die. The design of this type of product is the simplest.

The oblique screw hatch consists of a frame with two handles and a hole. It contains two prismatic sliding sweeps. The stop screw coordinates the placement of the runs. Crackers and dies have a robust installation to ensure matching thread threads on the rails. The exact installation of the rails and crackers is guaranteed by triangular protrusions in the frame and corresponding recesses in the dies and cracker.

Breakage of the runs is excluded due to the transfer of pressure on them from the screw by means of a cracker. A specific thread diameter should correspond to a separate set of dies. When installing sweeps in the hub, follow the numbers on the frame and the dies - they must match. Incorrectly installed runs make the threading process impossible.

Helpful advice! When threading a rod, the outer diameter of the turns should be 0.3-0.4 mm larger than the diameter of the rod. In this case, the cutting is of the highest quality.

2. Klupp Majewski

Klupp Majewski is designed for cutting turns on pipes with a diameter of up to 2 ”.

The basis of the mechanism is a frame with a groove in which adjustable runs are planted, which are fastened with a stop cover. Screws coordinate the placement of dies in windows. A guide flange is installed on the klopp frame. In it, the guide bushings are placed. Dies are provided for each pipe diameter. The rotation of the tool is done by the handles.

The advantages of this type of device are its simplicity and low weight. The use of a light screwdriver is especially convenient when applying threads on small diameter pipes.

Helpful advice! To achieve the exact installation of the rails, the corresponding numbers and risks are provided on them and on the hull of the hob.

3. Pipe screwdriver

The most common device for threading pipes is the so-called pipe screw die. The tool is designed to create slices with diameters from 1/2 ″ to 2 ″.

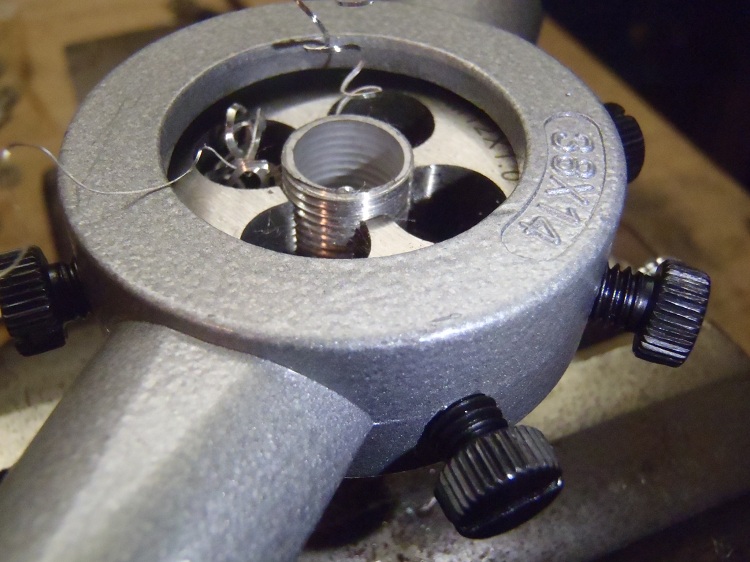

The case made of cast iron is equipped on the one hand with three rectangular grooves for guide dies, and on the other hand, with four slots for cutting runs. The pins are fixed in the dies. They enter the holes of the split ring for guide rails. The pins in the cutting rails are placed in the recess of the adjustable ring. Clamping rings are a means of attaching split rings to the frame. The rotation of the rings causes the dies to move in the radial direction. This movement corresponds to the diameter of the thread to be obtained. The movement is due to the grooves having a spiral shape. The screws are designed to tighten the split rings. Rotation when cutting turns is done using handles.

This kluppe provides two sets of runs. The first generates threads with a diameter of 1/2 ″ and 3/4 ″, and the second turns with a diameter of 1 ″, 1 1/4 ″, 1 1/2 ″ and 2 ″. There are serifs on the ring indicating the placement of the ring when threading the required diameter. The runs of the first set are cut only on one side, and the dies of the second set are double-sided. When installing them, it is necessary to pay attention to the numbers that are printed on the frame of the klupp and on the runs themselves.

Helpful advice! Cutting a thread with a diameter of 1 ″ or more, the split ring should be brought to serif only at the final passage. On the first scrolls this is not recommended.

4. Ratchet screwdriver

A tool of this kind is a modification of the device of the simplest constructional design. The built-in ratchet mechanism or ratchet makes working with the screwdriver as easy as possible, increases the speed of cutting turns. There are rattles left and right. Designed to facilitate work in hard-to-reach places and optimal transmission of effort. The device is very easy to use. It can be quickly removed from the thread by reverse rotation of the handle by turning the ratchet lever.

With careful use, the ratchet serves for a long time. In the event of a breakdown, a gas key can be used instead.

How to choose a screwdriver

The price range of these tools in the markets and in stores is quite wide. The quality of the goods depends on the cost.Buying an expensive mechanism is necessary only if you are a professional, or if as a result of the work it is necessary to obtain a result of high accuracy. When choosing a tool, you need to pay attention to the quality of the steel of which the cutters are made. It is preferable to choose doped. For the tool to last a long time, it must be purchased with replaceable cutters. Cutters from different manufacturers have different overall dimensions and do not always fit the same screwdriver.

The designation in the model name indicates the diameter of the pipe that can be processed with it.

The principle of threading on different types of surfaces

Bolt Threading Algorithm:

- clean the surface of the workpiece from contamination;

- clamp the part in a vice in an upright position;

- remove the scale from the bolt and saw off the chamfer at the end of the threaded part;

- create a thread (solid runs create a thread in one pass, and sliding in 2-3 passes);

- cool the run with drying oil or sulfofresol.

Algorithm for applying threaded turns on pipes:

- if the pipe is not new and has already been in operation, it is necessary to clean it of dirt or paint;

- fix the pipe motionless;

- in the place to be processed, apply drying oil or oil;

- put the screwdriver on the pipe while unscrewing the locking screws;

- reduce the guide dies close to the pipe, gently striking with a light hammer on the handle of the clamping ring;

- fasten the guide rails with the locking screw;

- in the same way, install and fix the cutting dies, focusing on the notch of the required diameter of the cut pipe;

- pressing the screw head forward, rotate it clockwise;

- it is recommended to cut the thread gradually, without jerking, without rushing, making a stop through half a revolution so as not to bend the pipe;

- to remove the plug from the pipe, the dies must be diluted.

After making the turns, it is necessary to try to connect the made thread with the reciprocal part. You can continue to work only if the elements interact correctly. In the case of processing an old pipe, the threaded thread must be inspected for the presence of through slots. If the cutting is applied to a worn-out water pipe, it should be held with a gas wrench so that the force exerted during rotation of the die is compensated.

Manual thread-cutting screw die, like every tool, requires constant care. Long service life is provided only if the mechanism is used correctly. Therefore, after operation, it must be disassembled, cleaned of contaminants and lubricated. At the first signs of blunting of the incisors, they must be changed to others of the same shape and size.