An electric pipe bender is a type of pipe bender that works by an electric drive. It can be used to bend almost any pipe. Unlike a hand-held device, an electric model can accurately and accurately bend a part even with very thin walls. In addition, electric pipe benders are designed to perform a large amount of work, so they are used in enterprises.

Content

Advantages and disadvantages

Electric pipe benders are professional, with a lot of positive qualities, devices. However, like any other device, they also have their drawbacks.

Benefits:

- high performance;

- speed of work;

- autonomy;

- universality;

- the ability to fine tune.

The above advantages are basic. A pipe bender of this type works very quickly and some models can be controlled using special programs into which the necessary parameters are entered. Such a device allows to minimize human participation in the process. Thanks to the programs, the accuracy of this machine is absolute. The machine bends to the nearest degree.

The main thing is that using such a tool, the worker will not have to use physical force. It is only necessary to carry out the adjustment yourself and place the pipe on the working surface of the product. The high speed of pipe bending on an electric machine allows you to perform huge amounts of work in a short time. The disadvantages of electrical models relate to his professional limitations. The main ones are:

- high price;

- impracticality;

- additional costs for electricity.

The automated pipe bender is distinguished by its large dimensions and weight. In addition, this device is expensive, so it is used in factories. It makes no sense for a home master to take such a bulky and expensive thing. But if you are an entrepreneur and decide to purchase an electric pipe bender for your production, then this is, without a doubt, a profitable investment.

Important! Some stationary pipe benders need power from industrial networks, the voltage of which is 380 V. Therefore, when choosing a machine, carefully study its characteristics.

Where are electric pipe benders used?

Electric machines make structures of various shapes, lengths and thicknesses, which later go to different needs. Let's consider some application options:

- towel warmer production;

- pipes for underfloor heating;

- spiral staircases;

- various decorative fences;

- elements decorating the interior.

Design and principle of operation of electric pipe benders

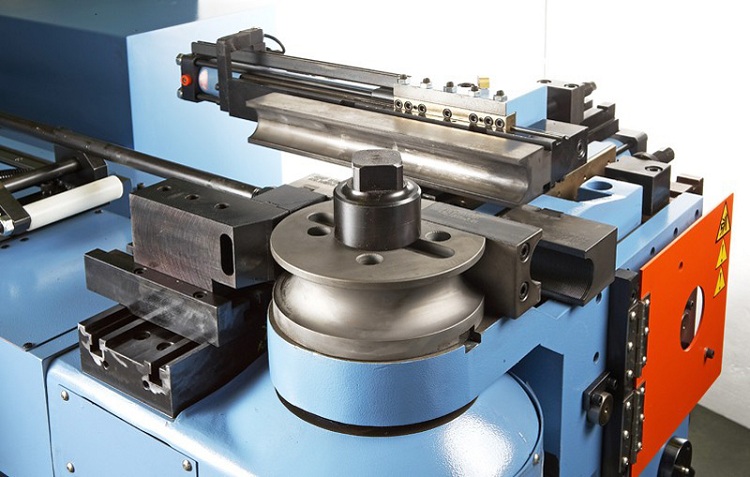

The main structural element of an automated pipe bender is an engine that creates a rotational load on a bent part. The rotor is equipped with a special nozzle.The shapes of these nozzles vary depending on the nature of the work. In addition, the ET device includes the following components:

- clamps;

- protective case;

- control panel;

- fixing devices.

Professional devices have special displays for managing workflow. Simpler pipe benders are equipped with control buttons and a small control panel.

Clips perform the following functions:

- protect against operator injuries.

- fix the bent part in the right position.

Due to the fasteners, the part is fixed in the required position.

At some enterprises there are ETs that carry out their work thanks to hydraulic elements. The process is as follows: the nozzle is located on the rotor, the engine creates pressure on it and it transfers the load to the bent pipe. Simply put, in such models there is no engine that creates torque. But this type of ET is rare.

Differences between stationary and manual ET

Designs, which consist of parts bent on pipe benders, are distinguished by their strength and reliability. The use of such a device is an excellent alternative to all kinds of connecting elements (fittings).

Note! Piping with fittings is a more expensive and less reliable option. Connection points are always considered problematic and often breakdowns occur in them.

To date, ET are represented by two main varieties that differentiate according to the principle of action:

- stationary;

- tame.

Stationary ET

Stationary devices are installed in a designated place. The mobility of such products is limited by size and weight. Such models are equipped with powerful engines and it is quite large equipment with a reliable frame.

The bendable part may have any characteristics. This can be a profile pipe made of ductile metal, characterized by thin walls, and durable pipes of large diameters, which are used for high-pressure water structures. Manual ET is a less productive, but also quite effective device.

Manual ET

This device is distinguished by its practicality. With its help it is possible to carry out bending of pipes in any places. It is lightweight and easy to transport.

Mostly manual ETs are used for bending plastic and metal pipes, which have average wall thicknesses and diameters of up to 40-50 mm. Bending of large profile metal parts is not performed on it. However, if the profile pipe has a small diameter and relatively small wall thickness, then its manual bending with an electric drive can also perform its bending.

Electric pipe bender: types

By the principle of action and the nature of the bend, these types of electric pipe benders are distinguished:

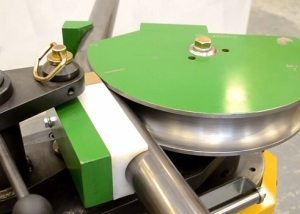

Winding. Such a mechanism bends the pipe due to the roller, which is rolled along the fixed pipe and as a result a part of the required shape is obtained.

Running in. Equipped with two twin rollers. The principle of operation of such devices is bottomless. They have a limited bending angle corresponding to the diameter of a fixed roller. To them, as a rule, sets of rollers are attached to expand the functionality.

Rolling. It has three rollers that function rhythmically. Such devices make various decorative elements from profile raw materials, which are used as decoration of interiors.

Extruding. The most popular type, which has the shape of a crossbow.When bending a part, the pipe fixed on both sides is extruded. However, the bending process takes a sufficient amount of time. The bending angle depends on the nozzle.

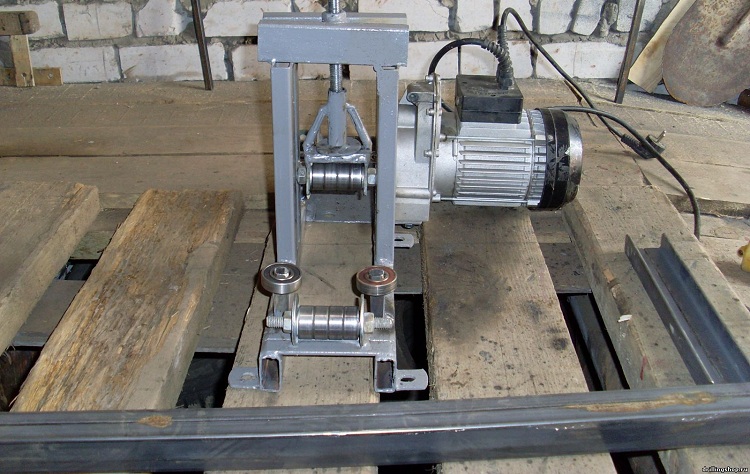

DIY assembly steps

DIY assembly of a pipe bender involves a number of steps. Consider the main ones:

1. At the very beginning, it is necessary to determine the frame for the electrical mechanism. Its design can be made of profile pipes. It is recommended to use rectangular shaped parts that have an average wall thickness of about 3 mm.

2. At the end of the profile pipe, it is necessary to drill a hole whose diameter must coincide with the dimensions of the axis. The distance from the end of the pipe should be at least 3 cm.

3. The third stage includes a number of very important processes:

- installation on the design of the control lever, which has a movable wheel that carries out the movement of the drive belt;

- installation of a stationary wheel;

- installation of a falling shaft. From the shaft end there is a pulley on which to install a belt drive from the engine;

- a star is mounted on the other end of the bed for the drive gear;

- mounting the second shaft.

4. At this stage, work is performed on trimming the profile part.

Important! Trimming the profile depends on the bending angle you want to get. In addition, it is recommended to take a margin of 5 cm. All excess is cut off. This can be done using a special hacksaw for metal.

The manufacture of an axis for a wheel and a lever can easily be done with your own hands:

- this will require two metal plates with a thickness of approximately 5 mm and with a width corresponding to the cross section of the axis;

- fold the plates together and attach a steel tube to them. Then weld the structure.

Next, you need to assemble the entire structure into a single whole. This is also done in stages:

- Fix the resulting ET frame in a vise.

- Install the axis.

- A wheel and a handle dock with an axis.

- The wheel is tightened by a bolt.

- The latch with a hairpin is established.

In order for the pipe bender, assembled with its own hand, to carry out its work due to electric energy, you need to connect an electric drive to a homemade machine. He will perform the rotation of the shaft.

Electric pipe benders are multifunctional and very efficient devices. The performance of this machine is high. It is ideally suited for stationary installation in production. The choice of ET model must be approached with all seriousness, since this equipment is expensive. The study of its technical characteristics and consultation with specialists are necessary measures when choosing a device. But there are more mobile and practical hand-held electrical options that can be used in everyday life.