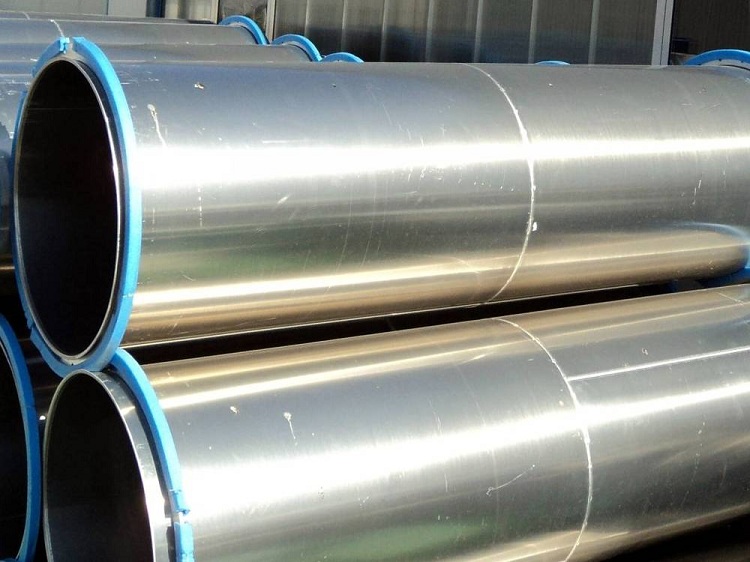

Precision steel pipe is a product that is manufactured with improved accuracy characteristics. Such samples have ideally measured inner and outer diameters. In addition, they are distinguished by a particularly smooth surface. These parts are used in a wide variety of industries, from automotive to space.

Content

About production materials

The precision alloy production process is unique and has many differences from other technologies. The main distinguishing feature of the precision composition is the absence of impurities. This result is achieved by melting the alloy in special media (for example, in hydrogen).

In order for the resulting alloy to be resistant to oxidative processes, it is subjected to hot working in a vacuum or other special medium. All the necessary physical and technical properties are achieved due to thermal, thermomechanical or heat treatment in a magnetic medium. All these processes are similar to the production of composite compounds. These alloys come off the conveyor in the form of tapes, wire thread, pipes, etc. They are used, as a rule, for systems and devices, where accuracy plays a very large role.

Features of precision tubes

Products with high accuracy parameters are indispensable in many areas. Such parts are used in the energy sector, in aircraft manufacturing. They are made using a special cold rolling technique, as well as using high pressure. Development in technical terms makes it possible to easily obtain parts with all the necessary characteristics and forms without much difficulty. A pipeline of this type has very high quality characteristics, due to which it gives a higher efficiency, as well as is reliable and has a long service life.

In addition to the high accuracy of geometric dimensions, precision tubes are particularly smooth surface

Precision pipes in pipelines increase its performance. In addition, the inner wall of the product does not contain scale, as with parts that are produced using the hot deformation method. And also they are distinguished by their aesthetics, since during their rolling a polished (mirror) surface effect is achieved. Precision parts are suitable for transporting water as well as for more complex tasks.

Important! In order for the part to differ in the most accurate dimensions, the honing method is used on the inner surface. This method is grinding and is produced by abrasive materials. As a result of honing, the pipe exits an almost perfect cylindrical shape without roughness and other defects. Honed products are used in engines of various types and cylinders.

To obtain an even higher level of cleanliness of the pipe surface, a protective coating of nickel or chromium is used. Products with a chrome-plated surface are common in hydraulic cylinders, have different hydraulic and ordinary pipe diameters and are distinguished by their efficiency, reliability and long service life.

Domestic production of precision pipes, although it differs from the western one in lower quality, but still allows you to get a fairly reliable product. The selection of precision products from Russian manufacturers is very huge. If desired, you can buy parts from a variety of materials, with any required length, diameter and wall thickness.

Precision pipes are manufactured on high-tech equipment in accordance with generally accepted standards

Such pipes are produced in accordance with GOST 8734-35, as well as 9567-75. The mechanical properties of pipes manufactured according to GOST 9567-75 are presented in the table.

Table 1

| Material grade | Resistance indicator | Flow rate | Approximate elongation (%) |

| 20 | 412 | 245 | 21 |

| 30 HCGS | 491 | – | 18 |

| 10 | 343 | 206 | 24 |

| 35 | 510 | 294 | 17 |

| 45 | 589 | 323 | 14 |

| 40 X | 618 | – | 14 |

Seamless cold-drawn hydraulic pipe

Seamless cold drawn hydraulic pipes are precision products and are used in the installation of structures operating from the pressure of water or another liquid. “Seamless” - this term means that the pipe does not have a weld, but this type of part is obtained using the cold rolling method.

In general, any pipes produced using this method are characterized by high reliability and accuracy and do not have scale on the internal and external walls.

Advice! In case of mechanical damage to the high pressure pipeline, it can be repaired using a conventional electric welding machine.

In addition, in the manufacture of such pipes phosphate surface. Thanks to him, the anti-corrosion oil previously applied to the pipe is absorbed into its walls. Such processing leads to the fact that the parts have a high resistance to destruction. Also, their surface is oiled or a special galvanic coating is applied to it (yellow chrome or galvanized), which also improves their quality and resistance to undesirable environmental influences.

Precision hydraulic pipes are a more accurate, robust and reliable option when compared with conventional ones. Such products are used for a variety of tasks. The range of their application is incredibly wide. The assortment of such products is represented by a variety of diameters, lengths, coatings, etc. A precision pipe is a durable part, the quality of which cannot be doubted.