A decade ago, the use of only smooth-walled pipes was considered in heating systems. Now the market for materials for mounting heating systems has replenished with an interesting novelty, which are corrugated pipes for heating. The combination of flexibility of the corrugation and the strength of stainless steel was very successful, and many modern heating systems are installed using these products.

Content

Advantages and disadvantages of corrugated steel pipes for heating

In addition to stainless steel, the corrugated pipe can be made of plastic or cast iron (products with external fins). Corrugated plastic pipes are not the best option as a pipeline for the passage of coolant. In heating systems, they are more often used as additional protection for the main communications, for example, passing in a cement screed. Cast iron corrugated pipes withstand heat loads well, but gradually fade into the background due to the large weight and complexity of installation.

Therefore, the best choice among all varieties of corrugations will be flexible pipes for heating from stainless steel. Their use has the following undeniable advantages:

- stainless steel corrugated pipe it is very easy to bend, this does not require additional devices and materials. Bending of the pipe occurs without risk to the integrity of the walls, so the structure can be given almost any shape. Due to this property of the corrugation, it becomes possible to mount the heating wiring with a minimum of bends and joints, which will significantly reduce its cost;

- stainless steel does not corrode, which means that the shelf life of such a system is several times longer than the operational life of a pipeline made of ordinary, "black" steel. In addition, temperature and pressure differences are also not a problem for stainless steel corrugations for heating;

- ease of installation - a quality that often attracts adherents of corrugations for heating pipes. Connections are made using brass fittings with o-rings made of various materials. When repairing certain sections of the pipeline, it will not be difficult to replace a system element;

- if large-scale work is necessary, a practically unlimited length of pipes will be a significant advantage. Sorting stainless corrugations for heating is carried out in bays up to 50 m. This should be enough for the device of any pipeline, but longer coils are also individually produced.

One of the most important advantages of corrugated pipes is their high flexibility, thanks to which you can save on corner fittings

Important! The maximum working pressure for stainless corrugations is 50 bar, critical - 250 bar. The normal operating pressure for hot media is 15 bar. Temperatures up to 110 degrees can be easily maintained for heating pipes made of corrugation, which is comparable with the properties of modern reinforced polypropylene structures.

Like any other product, flexible pipes for stainless steel heating systems have some disadvantages. How significant they are is for the buyer to decide:

- low impact resistance. If the corrugated stainless steel pipe for heating is mounted in areas of the house or apartment where its mechanical damage is potentially possible, it is recommended to use a protective casing;

- difficulty in leaving. Cleaning corrugated structures from dust is somewhat more difficult than pipes with smooth walls. Hygienic procedures will have to be carried out with a brush, and it is even better to hide the corrugation in a protective box or screen in advance;

- not the most aesthetic external component. When developing a model of a corrugated metal pipe for heating, manufacturers paid more attention to the functionality of the products than to their appearance. It is unlikely that you will call stainless steel pipes particularly attractive, but those who are not satisfied with this drawback can offer a ton of ways to hide the heating pipe.

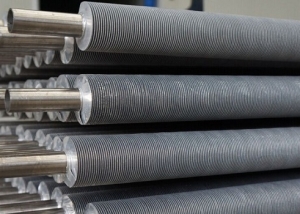

Production of corrugated stainless steel pipes for heating

The manufacture of corrugated metal pipes is a responsible process, therefore, each of its stages is fully automated. The stainless steel sheet takes a cylindrical shape when passing through a molding conveyor, after which a seam is welded on the workpiece.

The ribbed texture is imparted during the rolling procedure by rollers of various sizes. The elasticity of the corrugation is imparted by high temperature treatment. The bulk of the corrugation is made in South Korea. Most often on sale there are products from the following brands:

- Lavita. Lavita is a manufacturer of corrugated stainless steel pipes for heating, selling its products at reasonable prices. There are complaints about the strength of the pipe walls: when tightening the o-ring of the fitting, stainless steel sometimes cuts, causing leaks. True, this shortcoming can most likely be attributed to the consequences of illiterate installation.

- Kofulso. A stainless steel corrugated pipe for heating manufactured by Kofulso is considered to be the standard among other analogues. True, its cost will be several times higher than the price of pipes of the previous brand. Fittings for connecting these pipe models have o-rings with a special thickening, which contributes to better installation quality.

- Hydrosta. The price policy of the Hydrosta company is approaching the cost of products from Lavita, that is, it relates to the budget segment. But there is evidence that these pipes often have factory defects. Leakage of fittings occurs on average in 7 cases out of 100, and regardless of the degree of professionalism of installation.

- Meibes The quality of products from Maybas is at a good level. But the cost of their corrugations is considered unreasonably high.

High temperature and pressure in the heating system require the use of high-quality pipes, so you need to choose products from well-known companies

How to choose a corrugated pipe from stainless steel for heating

The choice of stainless steel corrugated pipe for heating should be approached responsibly and carefully. Fakes on the domestic market are not common, since the technology for producing stainless corrugations is expensive and complex. But the percentage of probability of acquiring a factory defective pipe is at least small, but it still exists. The quality of a flexible corrugated pipe is determined by GOST 3262-75.

When buying a corrugated pipe for heating, it is necessary to pay attention to the absence of damage visible to the armed eye. The distance between the corrugation segments should be the same throughout the length of the pipe. When bending and bending the pipe, the structure should return to its previous position, it is also necessary to check the absence of creases and deformations.

Helpful advice! The right choice of fittings also plays a significant role in the performance of the future system. There should be no cracks or other damage on the o-rings; the surface of the fitting itself should be flat and smooth.

It is also important to correctly calculate the required pipe length when purchasing. The volume of the heating system is calculated using information on the amount of coolant in the running meter of the product.

A good pipe connection can be achieved using reliable fittings from trusted manufacturers - for example, the same as the selected pipe

Table 1

| d pipe mm | The amount of coolant, l |

| 15 | 0,22 |

| 20 | 0,45 |

| 25 | 0,71 |

| 32 | 0,98 |

Features of mounting a corrugated steel pipe for heating

The process of installing a corrugated stainless steel pipe for heating has some nuances. First, do not abuse the ability of the product to bend: multiple bending in the same place sooner or later will lead to the formation of cracks and leaks. The flexibility of the material has a certain norm, so, having given the pipe the desired shape once, you should not change its configuration.

The installation of a pipe for heating from stainless steel corrugation resembles the method of connecting pipeline elements using compression fittings. The difference is that there is no fitting in the fittings for the corrugations. Crimping takes place due to inner lining fitting. Before a working start of the system, it is necessary to supply water as part of the test to determine if a leak has occurred at the joints.

Stainless steel corrugated pipe is a progressive solution for arranging a home heating system. Provided that the installation work is carried out correctly and the quality of the component materials and the pipe itself, the corrugated metal will be strong and wear-resistant.