The use of pipes is not limited to transporting only liquid media. They are used in electrical work or in the manufacture of various designs. The technical parameters of the pipe made of polyvinyl chloride (PVC) make it possible to become an important component of protecting communications. In addition, according to fire safety standards for such purposes, it is assumed to use not metal, but plastic products.

Content

The advantages of the location of the wiring in the pipe

Placing cables in a PVC pipe allows you to perform work in plastic, wood or other structures that are made of fire hazardous materials. Protected wiring will retain its technical and functional properties for a long time.

The wires do not require additional insulation in the form of shielding and various braids. There is also the possibility of easily diagnosing faults with hidden wiring and providing partial replacement of wiring.

Using PVC pipes avoids all kinds of damage during repair. Inside the pipe, conductors are allowed a higher current load than when the wires are located simply in the thickness of the wall. Due to its technical characteristics, PVC pipes for electrical wiring can be used for laying telephone, telecommunication cables, alarm and communication wires.

The main types of pipes

Specialists distinguish a large number of types of pipes for electrical wiring, among them: rigid, smooth, soft, reinforced, corrugated, etc.

Note! All PVC pipes for electrical wiring have good dielectric characteristics and do not require grounding.

Smooth products are used when it is necessary to conduct open electrical wiring on walls and ceilings of low-combustible or non-combustible materials. The characteristics of such PVC pipes are enhanced by the supply of additional insulation, as well as mechanical protection against cable damage.

Rigid PVC pipes for electrical wiring are used when it is necessary to conduct electrical wires in a concrete wall.

According to GOST 18599-83, pipes are classified into 4 categories:

- heavy (T).

- medium (C).

- medium-light (SL).

- non-standard (N).

Corrugated products are characterized by a variable cross-section. Due to the alternation of thin-walled sections of smaller diameter and thick-walled sections of larger diameter, it is possible to stretch and bend such pipes at different angles.

Pipes for electrical wiring can be selected corrugated or smooth; pull the cable in the last option will be easier

Corrugated Pipe for Electrical Wiring equipped with an internal broach - thin steel wire. They have two modifications: light and heavy, differing in wall thickness.

Range and characteristics of products

The market offers a fairly wide range of PVC pipes for electrical wiring. Their diameter can vary from 1.6 to 5.0 cm. The length of straight segments is up to 12 m.As a rule, the length of the products is 3 or 6 meters. They do not lose technical properties in significant temperature ranges from -25 to +60 ° С. Fire resistance of PVC pipes is up to 650 ° C.

For switches and sockets, a pipe with a diameter of 2.0 cm is better; lighting devices - 1.6 cm; messages of shields and distribution boxes - 2.5 cm; interfloor connections - 4.0 cm. Corrugated pipes are produced in bays of 200, 100, 50 or 25 m.

In the manufacture of pipes for electrical wiring, the use of additional additives is allowed, which give it the necessary color and do not affect the technical parameters. But there should be no foreign inclusions in the mass of material; cracks and chips in products intended for sale are not allowed. Storage involves no exposure to sunlight and the possibility of mechanical damage.

Protective pipes are available in different diameters, which allows you to choose a product for a cable of any cross section

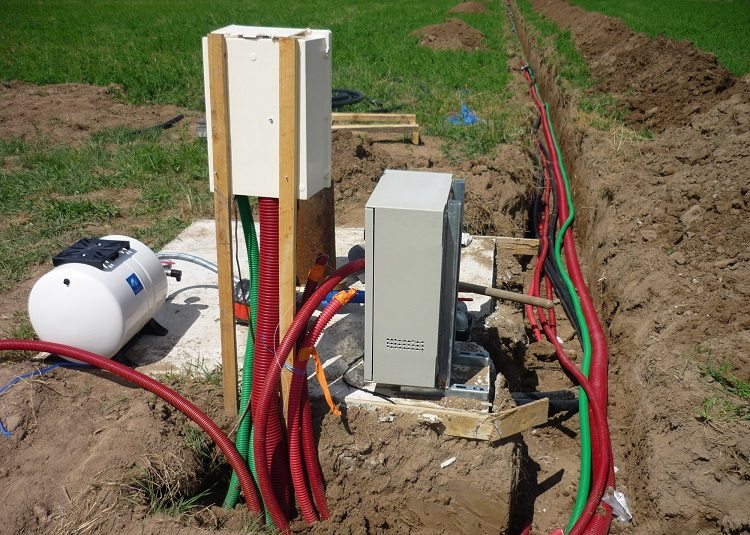

For underground laying, double-walled models of corrugated pipes are used, with a diameter of up to 20 cm. Pipe connections are made by typical connecting elements: couplings, bends, split tees and elbows.

Benefits of PVC Pipe Wiring

The main advantages of the application for the electrical wiring of PVC pipes include:

- high corrosion and chemical resistance;

- low weight, which greatly simplifies the installation of transportation of products;

- long service life;

- lack of need for wire protection;

- relatively low cost;

- the flexibility of small diameter specimens;

- lack of possible damages from hit of moisture.

In addition, the PVC pipe is rigid in structure, has a low coefficient of expansion (linear) and high mechanical resistance. Non-combustible polyvinyl chloride is used for the manufacture of wiring products, and the pipes themselves are produced by continuous extrusion.

Note! It is allowed to lay wiring in PVC pipes in rooms that have excess moisture, as well as in water or underground.

PVC products are used not only in residential buildings, but also in industrial complexes or administrative centers. They do not carry a large load on the supporting structure.

Rules for installing PVC tubes for electrical wiring

Only to ensure mechanical protection of the cables is the installation of an unpressurized pipeline. Moisture-proof construction protects the wires from other external influences.

Note! When crossing pipes for electrical wiring and an element of the heating system, it is necessary to ensure a gap between them of about 5 cm. Parallel pipe laying involves a distance of at least 10 cm.

To avoid heating the wires from the heating pipes, the wiring must be below their level. It is also not allowed to connect the wires inside the products. In such places it is necessary to install electrical boxes.

In rooms with a high level of humidity, it is necessary to install gaskets at the pipe connection points. If the moisture readings are normal, then this requirement is optional.

The presence of a broach in a corrugated pipe for electrical wiring requires special care to cut it, since the rigid steel wire is in the product with some tension.

In the places where the cables are connected, special boxes must be installed, since the connections cannot be placed inside the pipe

To fix the pipe to the wall or ceiling, aluminum or plastic clips are used. First, the location of the ends of the pipes is marked, and then the wiring route, the angles of rotation, the fixation point, the location of the boxes are determined. Bending of plastic pipes is possible at 100 ° C.The metal elements of the wiring are grounded and nullified using jumpers or grounding nuts.

Important Installation Points

A rigid or corrugated pipe is laid, taking into account some important points. When installing pipes in a brick wall or floor, metal brackets must be used. It is possible to fill the system only after its reliable fixation. Corrugated connectors are used to transfer the pipe to the wall from the floor or when it is inserted into the plate.

It is important to prevent the formation of creases, which will complicate the subsequent pulling of wires. If two points are connected in a straight line, then whole pipe segments are used. In the absence of a special probe in the kit, you can use an elastic metal or kapron broach. It is first launched into the product, and then a cable is attached to it.

Before broaching, cables are prepared by fastening them in several places. Reliable connection with the broach by twisting and tightening helps to prevent slipping of the harness. Make sure that the ends of the cable do not stick out. Otherwise, it will be impossible to pull.

Characteristics of PVC pipes for electrical wiring are excellent for reliable protection of cables from external influences and all kinds of damage with hidden or open installation. Their technical parameters fully comply with the requirements for this type of product.