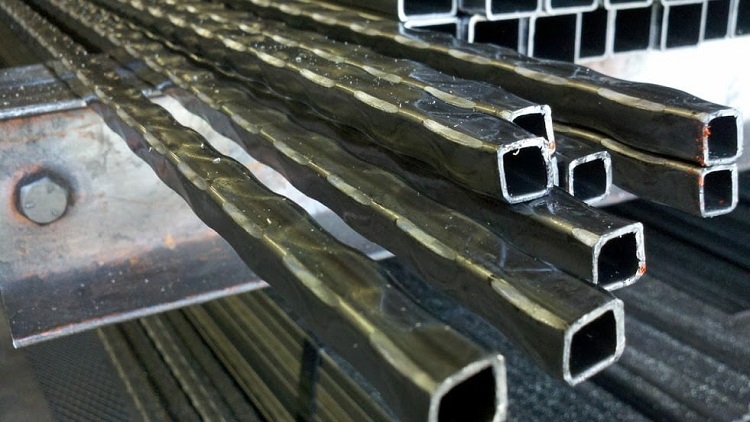

Decorative pipes are products that are used to decorate indoor and outdoor spaces. The inner part of such a product is no different from a regular pipe, however, the outer wall has a diverse (depending on the specific case) relief. Today, the assortment of decorative twisted pipes of various shapes and sizes is incredibly wide.

Content

What are decorative twisted pipes used for?

The main difference from standard hollow parts is their appearance, which is aesthetically pleasing. That is why they are used as decoration of the interior of rooms, as well as in the manufacture of various designs. Such non-standard products can be used under the same conditions as conventional pipes, and in some cases they are more efficient.

Such products are very popular in the construction industry, where various frame structures are made from them. Such designs not only look much more presentable, but are in no way inferior to conventional pipes in technical specifications. Consider the main structures and elements that use decorative twisted pipes:

- from decorative details, stands for arbors are often made;

- various non-standard fences;

- twisted products are very popular when installing gratings on windows;

- in addition, such parts are very popular in the furniture industry.

Twisted decorative pipes are used everywhere and the demand for them is growing every year. Due to this, new in form and complexity of product execution appear.

Features of the production of decorative twisted pipes in industry

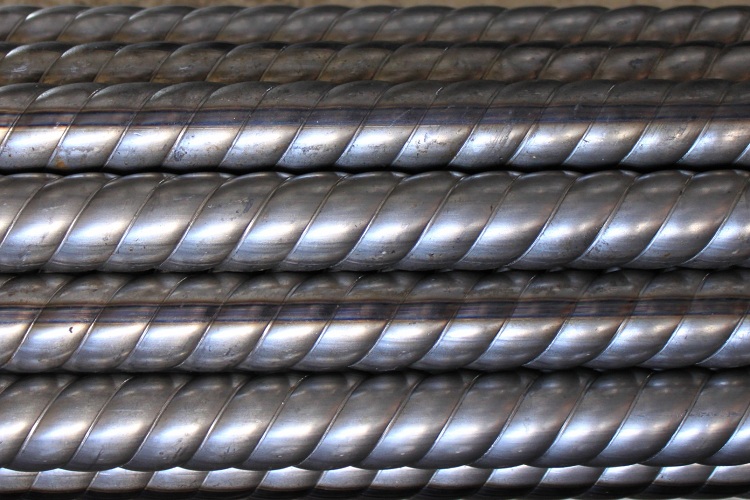

The production of such decorative products is not particularly difficult. In order to perform such a detail, you need an ordinary pipe, usually with thin walls. The most popular are those products that are made in a seamless way, however, and electrowelded parts are suitable for creating a decorative embossed pipe.

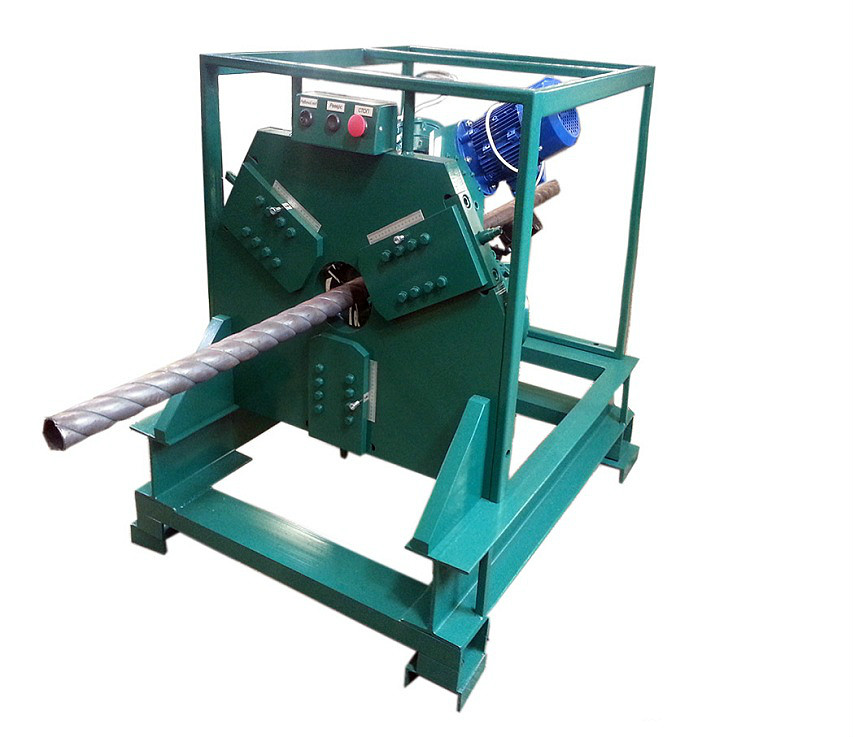

For the production of decorative twisted pipes, the workpiece is processed on a special rolling mill. The hollow part passes through the rolling rollers, as a result of which a certain relief is formed. The position of the rollers is regulated depending on the diameter of the pipe.

Helpful information! Rolling equipment for decorative twisted products includes three rollers located on a support. It is worth noting that each rolling part is usually equipped with an individual wire.

It is possible to adjust the caliper, which is used to strengthen the cutter. This allows you to process products with different indicators of the cross section and control the angle of inclination of the cut itself.

First of all, before the start of the workflow itself, it is necessary to set the necessary settings and adjust the elements of the machine so that it is possible to set the desired workpiece in diameter.

After the above actions, the calipers are brought together and fixed with the adjusting screw in the desired position. After this, you can begin the process of manufacturing a embossed part. It is also worth noting that the notch can be of two types:

- straight;

- screw.

Decorative steel pipes do not look as spectacular as non-ferrous metal products, but their cost is lower

There are no restrictions on the length or material as such. Embossed decorative pipes are made from ordinary steel and non-ferrous metals. The most spectacular look is the construction of decorative products made of non-ferrous metals, however, the cost of such products is higher than steel.

DIY pipe making machine

Not every owner can afford to purchase such an expensive product as a twisted (embossed) decorative pipe, however, if desired, this product can be made with your own hands. To do this, you will need to assemble a home-made machine, on which work will be carried out to obtain decorative parts.

Experts do not recommend doing this to those who are not at all versed in machine tools and their device. And for those who at least roughly understand the essence of the matter - this instruction may be useful.

Consider the main stages of the assembly of the machine to obtain metal with a pattern on the outer wall:

- First of all, it is necessary to make a special device that will serve as a support for working on a lathe (lunette). To do this, place three rollers in a specific position.

- Then you need to make the guide elements for the lunette. This will allow the support member to slide over them.

- The electronic part of the equipment must have a motor and chain transmission. The workflow itself is quite simple: a round pipe is fixed in the cartridge, after which it is necessary to turn on the gear.

- Next, it is necessary to bring the supporting part so that the rollers fix the pipe and the lunette begins to slide along the previously installed guide elements.

You can assemble a machine for the production of twisted pipes with your own hands, but if you plan a large amount of work, it is better to buy a ready

Such a machine is perfect for irregular or even one-time use, however, it is not suitable for the manufacture of twisted decorative pipes on an industrial scale. Industrial machines have a lot of advantages compared to homemade ones: the ability to adjust the angle of inclination, the variability of the machined diameters from 10 to 150 mm, as well as high productivity due to speed (120 km / h).

Types and characteristics of decorative shaped pipes

A decorative profile pipe is one of the types of metal that differs from ordinary pipes in that it has a non-standard section shape. In addition, the inner diameter of such products has been changed, so they are ideal for fencing, as well as for the formation of frames of various designs. The range of profile decorative pipes is quite wide.

Helpful information! To perform various fences, as a rule, pipes are used that have a wall thickness of 3 mm.

However, there are also thin-walled products with a wall thickness of 1.5 to 3 mm. Such profile decorative details are used, as a rule, in the furniture industry. Parts whose wall thickness reaches 4 mm are considered average and are used for supports in fences, as well as running gears of various mechanisms. Profile relief pipes can also be thick-walled, with a wall thickness of up to 8 mm. Such products are used for carcasses of buildings and massive machine tools.

The most popular forms of a profile part with off-line faces are:

- rectangular;

- square.

The length of such products can be from 6 to 12 meters.The drawing on the details, as a rule, is selected individually for a particular case. The cost of decorative shaped pipes depends on the volume of purchased products.

The advantages of embossed shaped pipes

Like any other product, decorative profile hire has its advantages, which are worth paying attention to:

- such products are quite durable and have a long service life. If you use a decorative profile part for arranging the fence, it is recommended to correctly design the future design;

- the use of a relief profile allows it to be performed in combination with other materials (for example, with a brick support of the fence);

- in addition, the relief profile can be customized for any span, having previously measured and prepared it;

- good transparency of the relief profile provides a presentable appearance of the site from the inside as well as from the outside. Due to this, various plants growing on the site are not shaded;

- One of the main advantages of a decorative profile is a wide selection of products. If desired, everyone will be able to choose something suitable for his taste;

Important! Experts recommend periodically applying a corrosion-resistant coating to decorative profile products used to equip the fence. Subject to updating the anti-corrosion coating, the operational life of such a fence will increase several times.

- Another advantage of such products is their high strength characteristics in comparison with a regular, round pipe of the same thickness and with the same cross-sectional indicators.

The above advantages allow decorative profile pipes to occupy a confident position in the modern market of building materials.