Among all the common metal products, the most widely used are chrome pipes. Thanks to their practicality, protection against corrosion and aesthetics, products are used in many commercial and economic fields - from medical equipment to luxury office furniture. But before you make a choice in favor of a particular variety, it is worth understanding the technology of their production and classification.

Chrome pipes - a practical and aesthetic basis for creating a wide variety of designs and structures

Content

The difference between a chrome surface and metal

The chrome-plated pipe visually differs from conventional metal products with a smooth polished surface and a typical “silver” shine. This layer performs not only decorative functions, but also protects against corrosion (rust).

Chrome plating is a special type of metal working, and such blanks are completely ready for use. They do not require painting, grinding or varnishing, since the smooth anti-corrosion coating of pipes, fittings and other products has unique properties.

Corrosion protection is the process of enriching a metal surface with chromium compounds. In other words, it is the deposition of chromium on the outside of steel billets through a chemical or electrolytic reaction.

Chrome pipe specifications

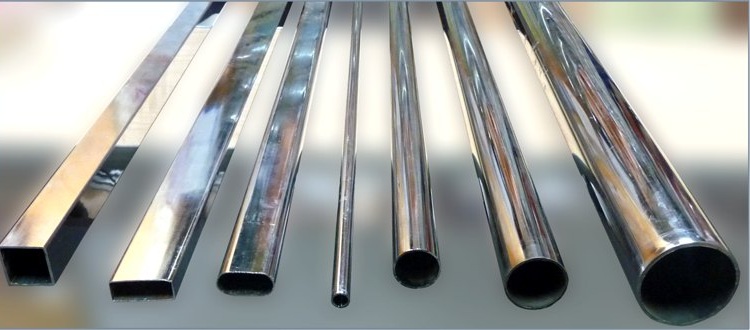

Chrome pipes have their own GOST, assortment and size chart for diameter and length. The shape is not only round, the square or oval chrome pipe is often used. Appearance - matte, shiny, colored pipes. Functionality - the frame or the basis of various products (from the pylon and bar counter to collapsible storefronts and medical beds). Chrome products are not only pipes, but also all kinds of components for them (fittings and fittings). The main classification is by diameter (internal and external section, the difference determines the thickness and functionality of chrome-plated products).

Furniture pipes with a chrome surface are available in diameters of 10, 16, 25, 32, 40 and 50 mm. From them produce:

- hangers;

- railing of metal and two-level beds;

- legs and frame of tables, chairs, banquets, armchairs and sofas;

- seats for waiting rooms of stations, etc.

Fittings:

- fastenings for glass display cases and shelves;

- door handles;

- nodal supports, holders and brackets;

- corners for furniture based on plywood, wood and chipboard;

- fittings and couplings for pipe joints (not only chrome plated).

Pipe Chrome Plating Technology

The production of chrome pipes and fittings is carried out in three ways:

- Electrolytic (immersion of metal in the tank with the connection of electrodes).

- Chemical (precipitate layer of chromium compounds from solution).

- Diffuse (saturation of the surface of the product with active electrons of chromium).

Depending on the organization of the process, you can get a different structure of the chrome coating.

- Aesthetic brilliant chrome plating with high wear resistance, for which 45 ° C - 60 ° C is enough.

- “Milk” chrome plating with low strength, but suitable for bending products, due to plasticity, which occurs in the range of 60 ° C - 80 ° C.

- Hard protected chrome plating with a large coating layer, which can peel off during soldering and bending.

Depending on the production technology, the strength of the chrome coating on the pipes may be different

It is interesting! Such surface treatment is used not only for coating from steel, but also from other metals, glass and some polymers. But utensils with such treatment are considered harmful to health.

Areas of application for chrome surfaces

The most common format is chrome “furniture” pipes for legs and frames with a cross section of 25 mm. Smaller diameters are thin tubes used for fittings. And thicker chrome pipes are all kinds of supports, bar counters, stairs, etc.

- Commercial equipment for sales areas:

- racks and shelves;

- carts for goods;

- exhibition stands;

- stair railing;

- design installations;

- mobile trading and pharmacy windows of glass and chrome pipes with fasteners of the "joker" type.

- Plumbing equipment:

- heated towel rails;

- glass shelves on chrome brackets;

- taps and mixers, siphons;

- supports for sinks and washbasins in the style of hi-tech or techno.

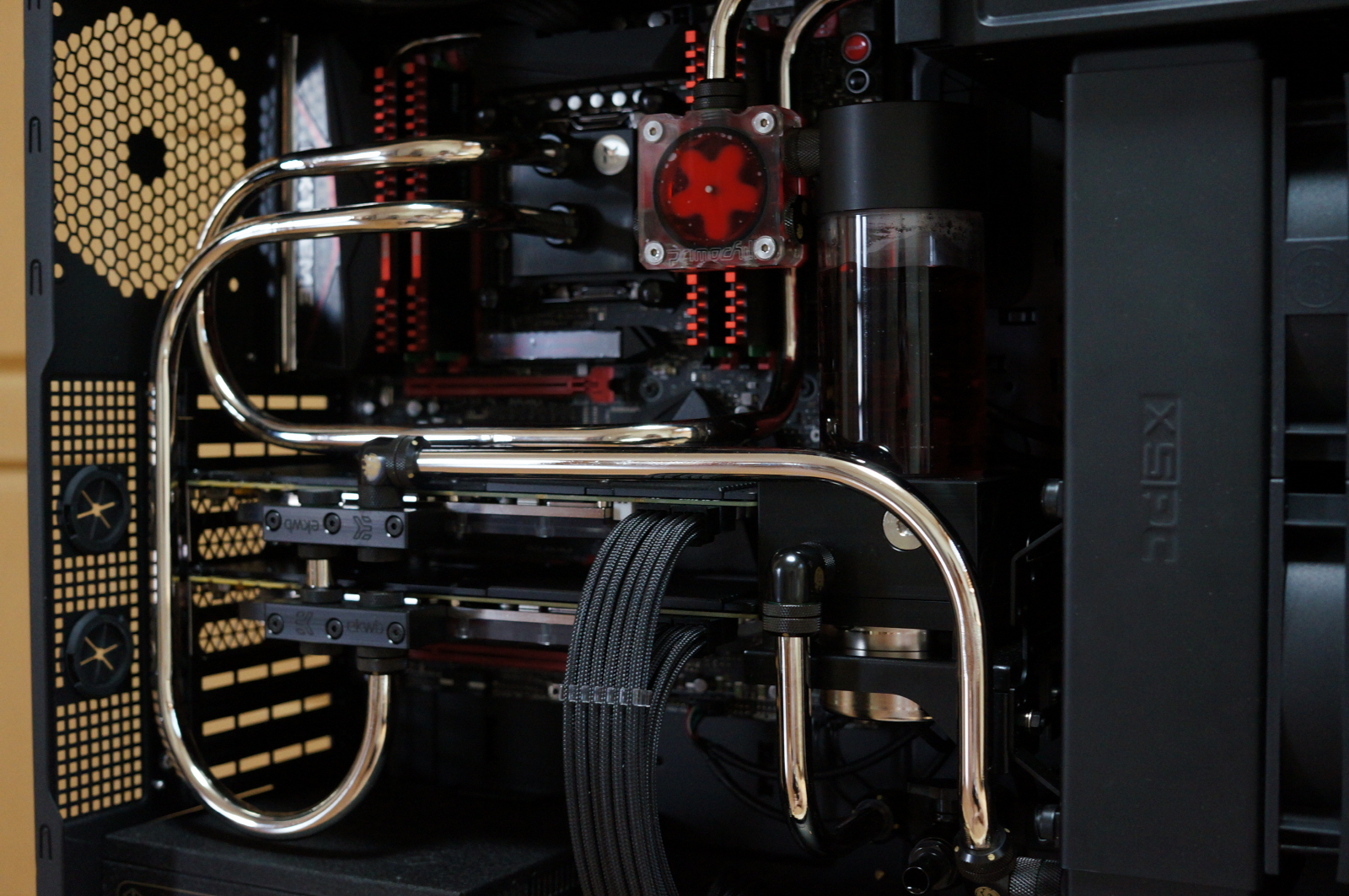

- Equipment:

- freezers (transportation of freon);

- air conditioners (exhaust pipe);

- steam and water equipment.

These products are also suitable for supplying various liquids in a variety of devices and units for domestic and industrial use.

- Appliances:

- chrome tubes of vacuum cleaners;

- tubes in electric kettles;

- details of gas and electric stoves.

- Automotive industry:

- exhaust pipes;

- thresholds, trim;

- motor tubes and other systems.

Important! Unprocessed legs of homemade metal furniture will scratch the floor, so it is advisable to provide them with tips.

How to work with chrome products

Externally, a very durable layer can be damaged during processing. Professional Tips:

- when making furniture from chromed pipes "artisanal", it is important to consider that the products will be tested for strength, so the reliability of the joint or welding is very important.

- work with chrome pipes, despite the strength of the coating, involves a leisurely and accurate cutting, bending and heat treatment.

- heating is carried out gradually, without open flame. The easiest way to work with thin-walled pipes.

- thin-walled blanks are cut with a hacksaw for metal, it is not recommended to work with a grinder due to a rough edge. Soldering - with electrodes, a blowtorch is needed for heating.

Advice! When cutting workpieces, barbs are inevitable, which are processed with an average sandpaper, file or file for metal.

- holes for bolts in thick-walled products, for example, for stairs, are made with an electric drill with nozzles for working on metal. Automatic drilling is done at low speeds.

- fix pipes need a vice, but so as not to peel off chrome plating. To do this, it is better to wrap the edges of the products with a soft cloth or corrugation made of polymeric materials. To soften the fixation, the working surface of the vice can be pasted over with felt (an overcoat cloth, boots of felt boots are suitable).

Before assembling the product on bolts or fittings, it is important to sketch a sketch to represent the appearance of the product. It will be easier to draw up a drawing for it - for precise cutting of tubes, for example, under chairs or a banquet. It is convenient to work on a cardboard or plywood template. Joining parts using fittings is preferable, but they should also be chrome plated.