When laying electrical wiring and cables, transporting various media, a flexible hermetic metal hose that can be quickly mounted due to the presence of connecting fittings helps. The grounding of the metal hose is made according to the requirements of the rules for installing electrical installations (PUE), so that in case of an emergency, the electric field between the earth's surface and the metal of the sleeve is safe for humans.

Content

How to produce stainless steel corrugated hoses

Such flexible and sealed stainless steel corrugated hose designs are performed, as usual, using high quality steel or another metal. The design is equipped with connecting fittings made of the same material, which simplifies joining of individual pipeline elements. A metal hose manufactured without fail receives a passport and certificate.

Airtight stainless metal hoses are produced in several ways. The most common are two of them:

- Forming a seamless metal tube with a diameter of up to half a millimeter.

- By overlapping the winding of the profile tape and connecting the edges of the corrugation by means of contact-roller welding.

The method of formation and the choice of metal for production determines which type will be given to the product:

- annular;

- spiral.

Sleeves are produced in and without braid, but even the presence of such a protective coating does not cancel the grounding

The production of corrugated metal hoses includes reinforcement with steel wire. The spiral sleeve is reinforced in a spiral.

Helpful information! The braid is designed to protect the product from mechanical damage. Depending on the purpose of the product and the pressure of the working medium, several braids can be made.

Marking with nine values is mandatory applied to manufactured products:

- year of manufacture;

- serial number

- main technical characteristics.

The use of flexible metal hoses

Flexible metal hoses provide reliable protection against mechanical damage and the occurrence of a fire caused by a short circuit when laying:

- computer network;

- television cable;

- video surveillance systems;

- telephone cable;

- electrical wiring.

In rooms with high humidity, products equipped with an additional protective coating of PVC are used. PVC sheath helps prevent dust and water from getting inside, even with a directed stream. Therefore, the design in the PVC shell successfully protects the cable laid inside it:

- in a production room with a high level of humidity;

- in a shower cabin and a bathroom;

- on the kitchen;

- in the sewer line.

Fasteners are carried out using brackets.

It is not difficult to select the product necessary for operation under certain conditions, as well as fasteners for a metal hose. The assortment is diverse, you can choose a product with a diameter of an internal passage from six millimeters to a hundred for cable laying.Moreover, in the range of 6-38 mm, the step of changing the diameter value is small.

Airtight stainless steel hoses

Flexible and tight stainless steel hoses are able to work in a wide temperature range, withstanding heating to 600º C and cooling to -270º C. Working pressure can reach 350 atmospheres.

To work in difficult conditions, apply those types of hoses that withstand high temperature and pressure

Products find application:

- when transporting gaseous, bulk and liquid media, including those characterized by aggressiveness;

- in units where they absorb mechanical vibrations resulting from dynamic working conditions;

- when connecting the individual elements of units and pipelines.

Products are available with various types of end fittings: for welding, threaded, flanged.

Note! Welded joint is the most common due to the relatively low cost. But it requires the use of welding equipment and makes it difficult to dismantle and replace a separate section.

Mounting sleeve for metal hose

Installation of metal hoses is not difficult. Fastening to surfaces allows staples to be made, and to connect individual structural elements - couplings. The latter are distinguished by several characteristics:

- length

- diameter of the connecting passage;

- material of manufacture;

- conditional working pressure;

- working temperature.

The most common types of couplings are:

- pipe. Serves to connect the metal hose and the wiring pipe. It is made of zinc alloy, equipped with a cylindrical thread;

- introductory. An introductory coupling for a flexible metal hose allows its tight entry into the mounting box. For production, self-extinguishing PVC is used.

- connecting. It is made of zinc alloy for joining individual segments.

An introductory clutch ensures the safe functioning of the most complex sections of electric networks, where they branch out and special junction boxes are installed. The coupling, without reducing the level of protection of the wires, leads the cable route into the junction box.

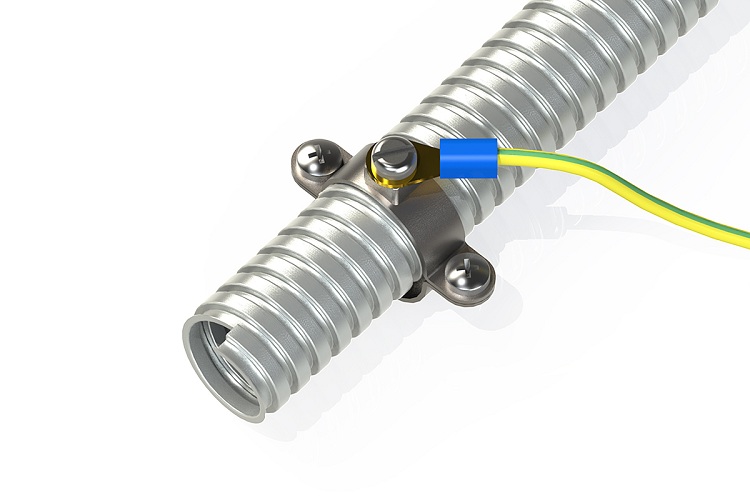

You can ground a sleeve with an electric cable passing through it using a steel clamp, which should clasp the pipe as tightly as possible

Hose Grounding

When using metal hoses, attention should be paid to the grounding device. The product itself provides electrical wiring protection thanks to a galvanized steel layer that conducts electric current well. Grounding will ensure an appropriate level of safety. The use of natural elements as grounding conductors significantly increases the efficiency of grounding. In the event of an emergency, when a person is included in the electric circuit, the magnitude of the voltage passing through it will not pose a threat to health and life.

Important! The protective case is especially grounded, which during installation work was not fixed with brackets (or other fasteners were used).

The grounding technology of the protective case involves several stages:

- The case is brushed to shine and wrapped around a metal bracket.

- A ground screw is attached nearby.

- A metal bracket and a grounding screw are fastened with a jumper - a copper wire with a diameter of at least 4 mm.

When conducting grounding, it is important to comply with the rules of the PUE, prohibiting, for example, the laying of even cables protected by a metal hose on a wooden surface.