Despite the fact that in the device of water-gas communications mainly round pipes are used, products with square and rectangular sections are in no less demand. The special form of profile products allows us to solve completely different problems in which the more familiar round-section pipelines would be useless. We will figure out what characteristics square pipes have and in which areas they are more in demand.

Square tubes are called profile pipes and are available in different sizes and from different materials.

Content

- 1 Profile square pipe: varieties

- 2 Features of square steel tubes

- 3 Features of aluminum square tubes

- 4 Characteristics of Plastic Square Tubes

- 5 Square steel pipe: range according to GOST 8639-82

- 6 Aluminum profile pipe: assortment according to GOST 18475-82

- 7 Scope of variety of square pipes

- 8 Using square pipes for gutters

- 9 Use of square pipes in ventilation systems

Profile square pipe: varieties

Square pipes may differ in material and manufacturing method. The following materials are used:

- aluminum alloys;

- plastic (PVC, the more expensive option is metal-plastic);

- steel of various grades.

Technical characteristics of metal pipes will also depend on the method of their production:

- cold-deformed seamless - refers to both steel and aluminum pipes;

- hot-deformed seamless - applies only to steel pipes;

- electric-welded - both steel and aluminum pipes.

Steel profile pipes are also classified according to the type of wall thickness:

- thin-walled;

- thick-walled.

According to this parameter, aluminum profile pipes have no distinctions. Wall thickness can be different in all areas of the same product.

Steel square pipes are highly durable, they are used to create building frames and other supporting structures

Features of square steel tubes

Square-section pipes are not the only products from the category of profile designs. Also, profile pipes are triangular, oval, rectangular and even hexagonal. After the square, the most common from this list are square pipes.

Square steel pipes are mainly used as frames, which proves their high strength. These products also have the following advantages:

- non-susceptibility to deformation. Square pipes can withstand the same load as an identical sized metal bar. The load on each structural element is distributed in parallel with respect to any of the planes, so it is very difficult to bend a profile square pipe.

- light weight. The strength of square pipes made it possible to significantly reduce the wall thickness of the products, and at the same time reduce their weight. Therefore, both installation and transportation of square pipes requires less financial, physical and time costs.

Features of aluminum square tubes

Pipes made of aluminum have many disadvantages as well as advantages over steel or copper products. In the frame structure, the most effective was the use of square steel pipes.

Aluminum profile pipes are better suited for light and temporary structures, and are also sometimes used in landscape and interior design.

- resistance to corrosion. The surface of pure aluminum is covered with a thin layer of oxide, which acts as a protective shell from environmental influences. Therefore, aluminum transfers the transportation of chemically active liquids, acidic media and gases quite painlessly;

- smooth surface. Aluminum pipes have a less rough surface than steel or cast iron. This factor is important when the appearance of the structure is important: the aluminum profile after welding is easier to bring into a “salable” look;

- plastic. Aluminum lends itself well to machining; if necessary, it can be easily bent. Also, the aluminum profile behaves perfectly when welding;

- strength and flexibility. Strength indices of aluminum pipes, of course, are inferior to steel structures. But at the same time, pipes made of aluminum alloys are much more durable than products made of PVC and other types of plastic;

- reasonable cost. The average market value of aluminum products is much lower than the price of steel pipes.

Important! Recently, the use of aluminum pipes in any systems involving constant contact with humans has been strictly limited. This is because carcinogenic properties were found in this metal. For the same reason, round aluminum pipes are no longer used in water supply.

In its pure form, aluminum is too soft and ductile, and such properties are not relevant for any of the areas. Therefore, all aluminum products are made from various alloys with the addition of other elements: copper, magnesium, manganese. True, the addition of materials to the alloy makes it susceptible to corrosion, so profile products are usually coated with a layer of pure aluminum for better protection.

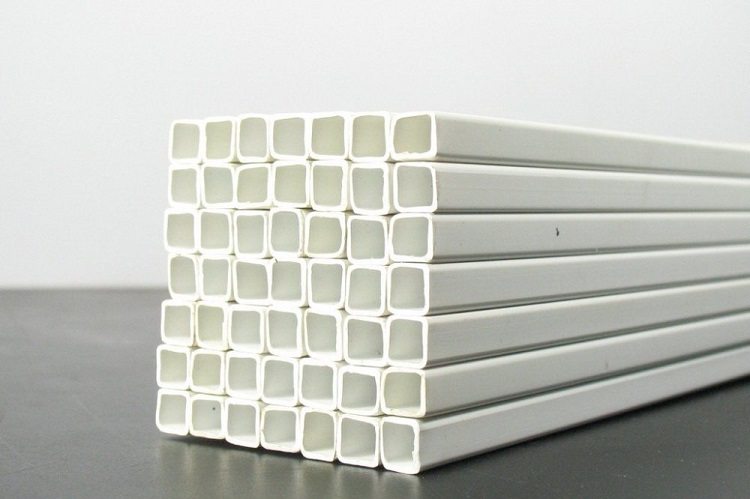

Characteristics of Plastic Square Tubes

Plastic is gradually replacing metal profiles.

Profile pipes made of plastic - the main competitor to steel products by weight and ease of installation

Polymer pipes are easy to manufacture, their mass production is not limited to natural resources. Another aspect is the environmental friendliness of such products, but, on the other hand, working with metals is also quite harmful to the environment.

For the production of most polymer square pipes, PVC is used. This material is not as durable as metal products, but it is completely not subject to corrosion and has a very low price.

- a light weight. Even aluminum constructions cannot compare with this quality of plastic. Indeed, plastic pipes are very lightweight, which simplifies the installation of large systems;

- surface smoothness. The manufacture of plastic products makes it possible to achieve almost perfect smoothness, thanks to which the transported substances (as, for example, in ventilation systems) pass quickly without lingering or settling on the pipe walls;

- aesthetic appearance. Air conditioning and ventilation systems cannot always be hidden behind furniture or fittings. And plastic ducts look quite neat and almost invisible in the interior.

Square steel pipe: range according to GOST 8639-82

This document regulates the rules concerning only products of profile rental. The assortment for a rectangular pipe defines GOST 8645-68.

Both electric-welded and seamless pipes are produced only in those sizes that are determined by GOST

The size range of square pipes includes various standard names. The size of the outer size corresponds to the method of manufacturing a steel pipe:

- cold-deformed pipe is available with an external size in the range of 10-120 mm. Their wall thickness will be 1-8 mm;

- hot-deformed seamless pipe - with an outer size of 60-180 mm. The thickness range of their walls is 4-14 mm;

- electric-welded pipe - outer dimensions 10.0-100 mm with wall thicknesses in the range of 1-5 mm.

In addition, the norms of GOST 8639-82 provide for special sizes for profile products indicated in the table.

Table 1

| Outer side size mm | Nominal wall thickness of the product, mm | Internal cross-sectional area, cm2 | Nominal weight, kg / 1 m | Moments of resistance, cm3 | Moments of inertia, cm4 |

| 32 | 4 | 4,20 | 3,3 | 3,33 | 5,33 |

| 36 | 4 | 4,84 | 3,8 | 4,47 | 8,05 |

| 40 | 2 | 2,98 | 2,34 | 3,54 | 7,07 |

| 65 | 6 | 13,55 | 10,64 | 23,66 | 76,91 |

Steel square pipes are measured and unmeasured lengths. Seamless cold-deformed pipe in accordance with GOST 8639-82 is available from 1.5 to 9 m unmeasured length and from 4.5 to 11 m measured. Hot-deformed pipes in both the first and second cases have indicators equal to 4-12.5 meters.

GOST 8639-82 provides for the presence of minor deviations in external dimensions:

- for square pipes with a side of up to 30 mm in any manufacturing method, the permissible deviation in the outer dimension shall not exceed 0.3 mm;

- with a side of 30 to 50 mm, the deviation does not exceed 0.4 mm.

- with a side of 50 mm or more, the deviation does not exceed 0.8%.

Tolerances for concavity (convexity) of the sides for seamless hot-deformed pipes according to GOST 8639-82 with sides up to 50.0 mm - 0.75 mm;

- from 50.0 to 70.0 mm - does not exceed 1.0 mm;

- from 70.0 to 100 mm - does not exceed 1.5 mm;

- from 100 - does not exceed 2 mm.

Deviations in concavity (convexity) of the sides for seamless cold-deformed, as well as electric-welded products with sides up to 50 mm - 0.5 mm;

- from 50.0 to 70.0 mm - does not exceed 0.75 mm;

- from 70.0 to 1 mm.

In fact, the square shape is attached to the round steel billets already during processing. An ordinary pipe with a circular cross-section is laid on rollers, where molding takes place. It is worth noting that such equipment for the manufacture of square pipes has a very reasonable cost. Because of this, there is a certain risk of acquiring low-quality square steel pipe produced in artisanal conditions. Such products will have a relatively low price.

But to make the final stage of heat treatment in unprofessional conditions is not possible. This fact immediately makes unsuitable profile pipes unusable: their strength will be very low, and their use is dangerous to human life and health.

Aluminum profile pipe: assortment according to GOST 18475-82

The state standard is distributed under the number 18475-82 (the validity period was extended in 1993) not only on profile products of square section (marking - HF), but also on round (KR), rectangular (PR) and (FS) - shaped parts.

According to the current GOST 18475-82, a cold-deformed profile pipe can be classified according to the state of aluminum after processing:

- annealed (marking - M);

- caked (N);

- hardened with natural aging (T);

- hardened with artificial aging (T1);

- cured, quenched with natural aging (VT);

- caked, hardened with artificial aging (T1N).

For the manufacture of square and rectangular profiles in accordance with GOST 18475-82, aluminum alloys of the grades AMg1, AB, and also D1 are used for annealed and chartered; AB and D1 are used for hardened and pipes with natural aging.

GOST 18475-82 (93) makes requirements for the evenness of aluminum pipes. Deviation from straightness should not exceed 1 mm per full 1 m of length. Smooth twisting of profile pipes is allowed within 1 degree per 1 meter linear. The transverse deflection of each side may be:

- 0.5 mm - for pipes with side up to 50 mm;

- 0.75 mm - for pipes with a side of 50 mm or more.

Profile pipes according to GOST 18475-82 (93) with a diameter of up to 32 mm go on sale without preliminary deburring.Other sizes include stripping at the request of the customer.

The inner and outer surfaces of square pipes must not have non-metallic impurities, cracks, spots, scratches, bubbles, or other mechanical damage.

Scope of variety of square pipes

Square tubes are used in a wide variety of construction and industrial sectors.

In particular, these are:

Furniture industry. Almost all trade racks, display cases and advertising constructions of a budget class are constructed on the basis of an aluminum profile. It is this metal that has gained such popularity due to its lightness, low cost and ease of installation. Steel profile is also used in this area, but mainly for more expensive commercial equipment and general purpose furniture.

Sewer systems. Sewer pipes are used mainly with a circular cross-section, according to GOST 8732-78 (for seamless steel pipes) and GOST 2268.9-89 (for plastic pipes). But square pipes can be applied in this area if they are used for irrigation of personal plots. Sewer pipes in this case are needed with a diameter of not more than 150 mm.

Individual and mass construction. Almost all frame structures are created using square profiles: from multi-story buildings to greenhouses and fences.

Engineering, shipbuilding. Almost every modern transport model has elements built thanks to square pipes. In the construction of ships, aluminum profile structures are widely used.

Cabling. Sometimes plastic pipes of small diameters are used as cable channels for wires.

Using square pipes for gutters

The type, dimensions and installation methods of drainage systems are regulated by GOST 7623-84. The same GOST provides for the use of square drainpipes.

Important! Gutter square pipes have the highest throughput. Therefore, on roofs with an area of more than 200 m2 the use of gutters with a circular cross section is not recommended.

Gutters are selected in accordance with the size of the gutter, since the cross-sections of these elements must match. GOST determines the standard pipe sizes for different roofs:

- for area up to 30 m2 drainpipes with a diameter of 80 mm are needed;

- up to 50 m2 - drainpipes 90 mm;

- more than 125 m2 - drainpipes with a diameter exceeding 100 mm.

In regions with frequent temperature fluctuations, it is advisable to install galvanized steel drainpipes. In other cases, the material of the product is not of fundamental importance. Aluminum structures are attractive low cost, lightweight and easy to install. At the same time, plastic drainpipes have significantly lower thermal conductivity, which means that ice plugs will not form in them.

Use of square pipes in ventilation systems

Square pipes are found in the duct structure at about the same frequency as the round one. It is believed that square and rectangular ventilation systems are less effective than round or oval, as they supposedly withstand air currents. Consumers may also be confused by the fact that in pipes with a square cross section, noise during air transportation is more easily propagated.

At the same time, square air ducts do not cease to be in demand. To reduce sound effects, the ventilation system is mounted together with soundproofing material. Plastic square pipes generally do not contribute to the propagation of sound compared to metal counterparts.

Helpful advice! During installation of the plastic ventilation system, it is advisable to treat the pipes with an antistatic agent so that the plastic does not attract dust from the air.

Consumers are offered a wide selection of square pipes made of various materials. The assortment of the profile pipe according to GOST includes a fairly complete dimensional grid, which allows you to create structures of any scale and purpose. All bona fide manufacturers strive to comply with the norms prescribed in state standards, so today it is very rare to have problems choosing the right profile pipe configurations.