Ventilation pipes made of stainless steel with galvanization have found their application as ducts in the industrial and domestic sectors. The main purpose of the ducts is the supply of clean air to the room and the disposal of waste. Exhaust systems made of galvanized steel are only rigid, they are distinguished by high aerodynamic properties. Galvanized ventilation is also suitable for roofing and central climate systems.

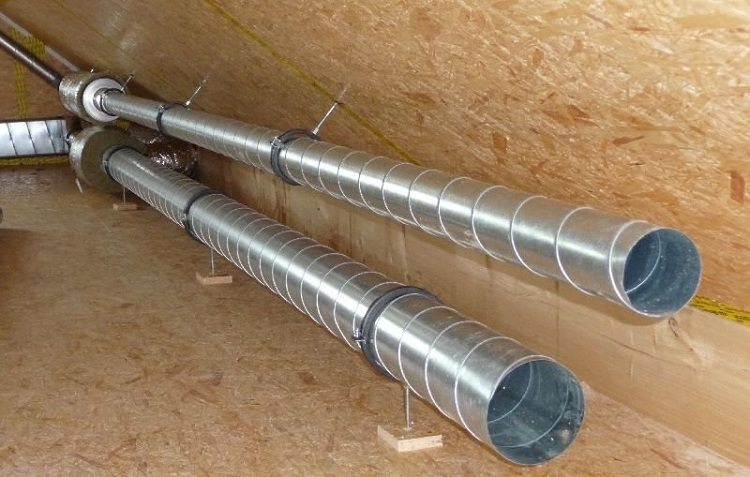

Ventilation systems in residential, industrial and other purposes are often mounted from galvanized pipes.

Content

Galvanized Steel Ventilation Pipes: Classification

The main characteristic that affects the classification of galvanized ducts can be called the cross-sectional shape: such pipes are square and round. The latter, in turn, differ in the method of manufacture. Straight-seam and spiral-wound round ducts are used. To connect pipes of circular cross section, regardless of the method of their production, nipples are used, although the use of flanges is possible. Rectangular pipes can have both flange and flangeless connections. The cost of spiral-wound air ducts is approximately the same as that of rectangular channels.

Thanks to the galvanizing layer, ordinary “black” steel can become prone to corrosion. The appearance of rust is the main problem inherent in all metal products.

The properties of all types of galvanized steel ducts are as follows:

- long service life (in comparison with plastic air ducts and channels from other types of metal);

- zinc provides protection against aggressive environmental influences (the thickness of the galvanized coating may depend on the conditions in which the duct will work);

- the lightness of the material provides ease of transportation and installation of the system.

The use of ventilation pipes made of stainless and galvanized steel, according to GOST quality, is allowed in rooms with a constant air temperature not higher than 80 degrees and with a humidity not exceeding 60%. Ducts must be produced by cold rolling, have a wall thickness of not more than 1 mm. It is allowed to use some parts of the hot-rolled system with wall thicknesses up to 0.9 mm (excluding the galvanized layer).

Spiral ventilation pipes: characteristics

Such products are made from a strip of galvanized steel, the width of which is 137 mm. The metal strip is twisted in the direction of the spiral. The edges of the steel strip are interconnected by a locking method. This design has stiffeners providing strength to the product while maintaining lightness.

The advantages of this kind of ducts can be called:

- significant rigidity;

- ease of installation due to light weight;

- the possibility of savings due to the reduced number of fittings;

- passing through a spiral-navigated channel, the air turbulence increases, so the noise level during air duct operation decreases.

For spiral-wound pipes, sheet steel is used, the thickness of which depends on the diameter of the product. For pipes with a diameter of 150 to 355 mm, galvanizing is 0.55 mm thick, for pipes with a diameter of 400 to 800 mm - 0.7 mm. Millimeter galvanized steel is necessary for the production of large diameter ducts, from 900 to 1250 mm. Sections of 3 and 6 meters are on sale, but by an individual order, manufacturers produce pipes of arbitrary length. Also, in accordance with the order, spiral-wound pipes can be reinforced with additional stiffeners.

Properties of longitudinal welded round ventilation pipes

For the production of such structures, sheet steel with galvanized coating is used. The edges of the sheet are fastened together by a nipple connection. The sheet cutting process is automated, this operation is performed on a special machine. In the manufacture of custom-sized air ducts for an individual order, the material must be labeled manually, and it is cut on a manual guillotine machine. The pattern is wrapped in a pipe of the required diameter on the rollers, and then fed to a folding machine. Folding is performed along the length of the longitudinal edge of the product.

Pipes for ventilation longitudinally galvanized are characterized by such qualities:

- their design provides fast movement of air flows;

- among all types of pipes, their aerodynamic characteristics are the best;

- air flows through longitudinal pipes quite quietly;

- The cheapest air duct options on the market.

The thickness of the steel sheets used for the production of longitudinal pipes does not differ from the steel necessary for the manufacture of spiral-wound ducts. The standard lengths of sections of such products are 1.25 m, the maximum length is 2.5 m. For the best tightness, pipe joints are treated with a special sealant.

Galvanized rectangular ventilation pipes

In the manufacture of this type of ventilation pipes, sheet steel is used, the thickness of which also varies between 0.55-1 mm and depends on the dimensions of the product. The minimum size of a galvanized rectangular pipe for ventilation is 10x10 cm. The maximum dimensions of the products are not limited, they depend on the production capacity.

The manufacturing process of rectangular ducts involves several stages. First of all, sheet steel is bent, stiffening ribs are formed on it. After that, blanks with a non-rolled longitudinal lock enter the assembly apparatus, where the longitudinal lock is clamped, and a fold is created, closed and rolled. Then, on the edge of the pipe, a splint-rail flange is attached, a corner is put on it. It is possible to apply a flange from a steel corner or the absence of a flange.

According to the tightness class, rectangular products belong to classes H and P. Rectangular air ducts of class P are made individually, their tightness is ensured by additional processing of the flange and longitudinal joints with sealant. Class H allows a slight air leak, which is within the safe standard. A well-sealed seam and its lock guarantee excellent tightness and without additional processing.

Rectangular ducts have two classes of tightness, the appropriateness of using each type depends on the operating conditions of the ventilation system

Like any ventilation structures, a rectangular duct requires periodic cleaning and checking the coating of the internal parts of the system.

Rectangular pipes fit better into the interior of production facilities, they take up little space, and therefore are better suited for rooms with low ceilings. But their use is associated with some difficulties. Firstly, they are difficult to install. Secondly, their aerodynamic performance is inferior to the characteristics of round products.

Galvanized steel fittings

Any ventilation system includes in its design not only pipes of a certain section, but also a whole complex of shaped elements. Thanks to these details, you can get any duct configuration that has twists, branches, etc. Shaped elements are used to connect several pipe sections and system units.

The assortment of shaped products includes the following items:

- adapters;

- cruciform elements;

- tees;

- outlet parts;

- corner elements;

- taps, tires, probes.

The connecting sections of the air duct are closed by elements that may have a different shape. Sometimes the proper organization of ventilation lines may include the number of fittings equal to the number of pipes used. For different ventilation pipes for the extraction of galvanized steel, elements with different cross sections - round and rectangular - are produced.

To create a properly functioning ventilation system, the following set of parts will be required:

- branch with an angle of 45 degrees;

- rectangular bend with an angle of 90 degrees;

- tee - if branching of the system is required;

- set of nipples;

- adapter - if connection of air ducts of different sizes or different levels is required;

- transition element from the hood to the duct.

It is advisable to purchase fittings from manufacturers that produce air ducts. The seller must have a quality certificate for all products. Ideally, the contractor should provide a warranty on the products as part of the service.

The location of the ventilation system

When organizing ventilation ducts, all installation steps must comply with SNiP requirements. If the duct is mounted during the construction of the house, then some of its elements can fit into special channels (strobes). Some of their most important provisions of SNiP are focused on the fire protection of the ventilation system. According to this document, pipes through which combustible substances (including household gas) are transported must be located not less than 100 mm from the duct.

If ventilation is located outside the building, it is necessary not only to carefully fasten sufficiently lightweight pipes, but also pay attention to their insulation. Otherwise, there is an increased likelihood of condensation, which can contribute to the occurrence of rust if the galvanizing layer is damaged for any reason. This operation is not required if the system is operating with forced air flow.

Secure ventilation pipes with reliable clamps, especially if the system is planned with forced exhaust

The location of the ventilation duct, its turns and branches corresponds to a previously developed system design. It is placed by attaching to the walls, ceiling, and sometimes to the supporting posts. The fastening frequency must be such as to avoid sagging of the galvanized steel ventilation pipe. The optimum distance between the mounts is within 3 meters.

Fixation of the duct can be carried out in the following ways:

- channels with a rectangular cross section are fixed using a profile and studs connected by self-tapping screws;

- round ducts are secured with a clamp and stud. Perforated galvanized tapes can also be used, for greater strength they are combined with clamps;

- large systems are fixed with a Z-shaped or L-shaped profile. Rubber seals are located in the attachment points - they protect the channel walls from deformation, compensating for the movement of the structure during the passage of air masses.

Hammered anchors are used to lay long ducts and large diameters.

Galvanized air ducts are the best solution for organizing a ventilation system in any area. It is better to lay very long systems out of rectangular pipes, since their cross-sectional area is larger and they are considered more practical. Rectangular ducts are easier to maintain and clean. On the other hand, it is recommended to install round pipes in areas with a high level of pollution, since in rectangular channels there is a higher probability of clogging of corners and ribs with garbage.