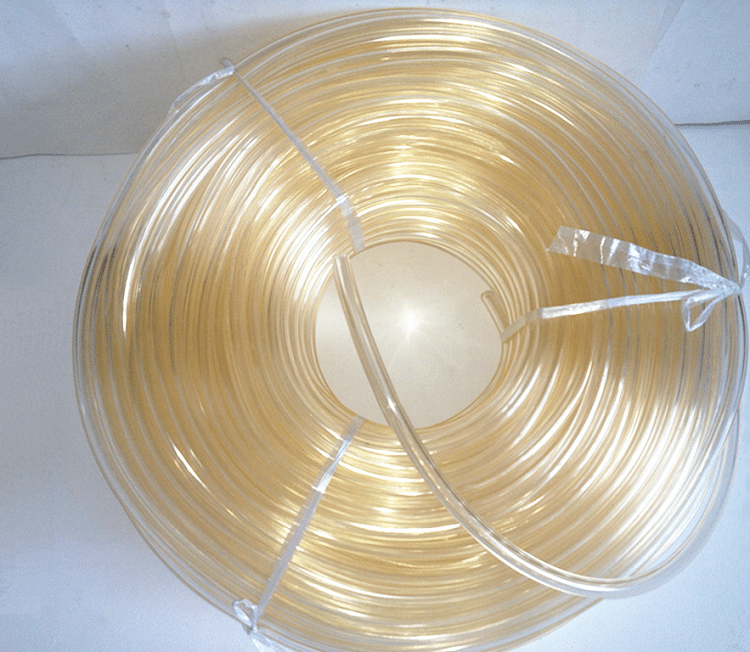

Transparent PVC tube - a universal part of pressureless pipelines. Due to its many advantages, it is very popular in the plumbing market. It is used both for commercial and industrial, and even domestic purposes for transporting liquid substances. What are its main pros and cons? What is the specifics of this product? When can it be used, and when should not?

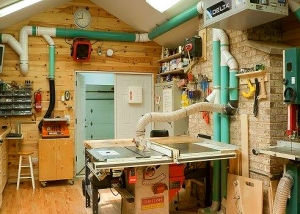

Transparent PVC pipes are used for the installation of water, ventilation networks and equipment for laboratories

Content

Polyvinyl chloride: main characteristics of the material

PVC is the first polymer material used to equip water supply systems. It is quite cheap when compared to other plastics and iron. Transparent PVC pipes are also used for ventilation communications, as well as in the production of laboratory equipment. Due to its chemical properties, a transparent polyvinyl chloride tube is not used for heating systems, since at high temperatures (above 100-110 degrees Celsius) it releases hydrogen chloride, which is harmful to human health. However, this property of the material made it popular: as a source of chlorine, it is used in pyrotechnics.

In addition to moisture resistance, it also has smoothness and repels dirt. Transparent PVC tubes can be installed almost anywhere, communications can have a variety of shapes and lengths due to the plasticity of the material itself and the ease of working with it during installation.

Advantages and disadvantages

The popularity of PVC pipes is due to their many advantages. Like other communications from polymers, they are characterized by:

- durability (service life is more than 50 years with proper installation and operation);

- light weight and compactness, which provides cheaper and easier transportation of transparent PVC pipes;

- easy installation method. Making communications from this material is quite simple, it can be done even without the help of specialists;

- low noise. Such a system functions almost silently;

- environmental friendliness. The material from which the pipe is made is absolutely safe for the environment. The polymers included in its composition do not interact with chemically aggressive substances and do not form harmful compounds;

- low thermal conductivity;

- unpretentiousness in service. Thanks to the smooth walls and simple structure, transparent pipes are easy to inspect and repair;

- resistance to destructive processes. PVC is a material that is not prone to corrosion (unlike metal, for example), it is also resistant to the negative effects of ultraviolet rays.

Despite the large number of advantages, this product has some limitations. For example, PVC pipes are produced only in small diameters and therefore they are not suitable for transporting substances on an industrial scale. In addition, they are usually not used for pumping hot liquids and gaseous compounds.

Mounting Features

PVC tubes are used in many sectors of the economy - from laboratory units to milking machines.Their specificity lies in the fact that they are used in cases where you need visual control over the transportation of substances.

Despite the fact that the transparent tube is easy to use and during installation, do not forget about some points regarding the installation of equipment.

A significant advantage of the polyvinyl chloride pipeline is its simplicity. You will need a minimum of accessories and equipment, and the procedure itself can be carried out independently. PVC is a pretty tough material. This makes it similar to metal and affects the technology of laying pipes. To calculate and plan the system, you can use the data for iron counterparts.

Installation of transparent PVC pipes is possible both by open and hidden methods, since they are made of a material resistant to the negative effects of ultraviolet rays. In addition, they are sometimes produced also with the addition of a layer of protection against oily substances and gasoline.

The algorithm of actions during installation does not represent anything complicated. You just need to choose pipes of the correct diameter, to connect using fittings and special angles at the turning points.