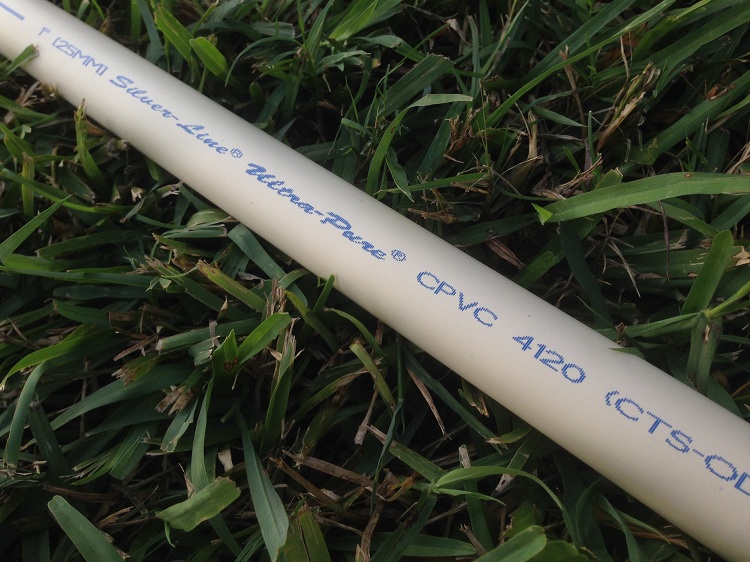

CPVC pipes are products that have been widely used in Russia since 2008. They are made from chlorinated polyvinyl chloride and are used for laying heating, water, gas and sewer communications. Parts made of chlorinated polyvinyl chloride have a lot of positive qualities compared to pipes made of other materials.

Chlorinated polyvinyl chloride pipes have both similar and different quality from ordinary PVC pipes

Content

The advantages of CPVC pipes

CPVC products have many advantages. This is due to the fact that initially this material was obtained in a US laboratory and used in the space industry. Consider the main advantages of chlorinated polyvinyl chloride pipes:

- ease of installation. Docking of individual elements of CPVC pipelines is done by gluing pipes and connecting elements - fittings. Bonding implies the formation of a monolithic compound as a result of mutual diffusion of materials;

- resistance to high pressure indicators. CPVC products are divided into three classes, depending on what pressure they can withstand (PN10, PN16, PN25);

- high environmental performance and resistance to bacteria allow you to lay pipelines of this material in medical institutions;

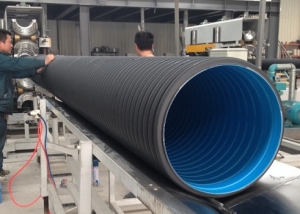

Note! Chlorinated polyvinyl chloride products are excellent for underground communications. This is due to the fact that they have corrosion resistance and also have good strength indicators. In addition, they are immune to trace elements in the soil.

- CPVC is distinguished by high hygiene indicators;

- the thermal conductivity of these products is 200 times lower than that of steel counterparts. It follows that CPVC communications do not need heat insulators;

- parts made of chlorinated polyvinyl chloride are characterized by high fire resistance and self-extinguishing when ignited;

- the service life of products from this material, as a rule, is at least 50 years (under normal use);

- resistance to harmful corrosive effects;

- resistance to aggressive chemical compounds;

- pipelines made of this material have a very small coefficient of thermal expansion. However, experts still recommend taking this factor into account when designing and laying pipeline structures;

- have good resistance to ultraviolet radiation, so they can be laid both underground and above ground;

- environmental friendliness. CPVC parts do not change the chemical composition of the transported water, do not affect its taste and smell;

- small mass. Due to its low weight, CPVC devices are easy to transport and assemble;

- smooth internal walls of the pipeline from this material exclude the possibility of salt deposits. Due to this, there is no narrowing of the lumen of communication and a deterioration in its throughput.

Of the minuses, it can be noted that the cost of parts made of CPVC is approximately at the same level as pipelines made of ordinary and galvanized steel.

Features of CPVC pipes

Conventional PVC pipes for water supply are temperature resistant up to 55-60 ° C, and CPVC products can be operated at temperatures up to 95 ° C. This is due to one of the areas of their use (for heating systems). For the installation of chlorinated polyvinyl chloride pipes, no special tools are required.

For the installation of CPVC pipes, special tools are not needed, such products are connected using an adhesive

Simple, from a structural point of view, communication from chlorinated polyvinyl chloride can be performed in a few hours, and a more complex system, as a rule, takes no more than two days. Subject to all installation standards, the chlorinated polyvinyl chloride pipeline construction will look very presentable. As mentioned above, individual elements of the CPVC water supply are joined by cold welding. This method is less labor intensive than conventional welding and does not require special work skills.

CPVC pipes light up at a temperature of 433 ° C (only with a direct source of fire). The reliability of these products has been tested over the years in other areas, so their use as elements of various pipelines is justified.

Types of chlorinated polyvinyl chloride pipes

To date, there are three classes of these products for pressure resistance:

- PN10;

- PN16;

- PN25.

In addition, products from chlorinated polyvinyl chloride are divided into two main groups.

You can understand what class the pipe belongs to and what its technical parameters are, by marking on the outside

The first group includes devices that are used when laying various communications in adverse conditions (at low temperatures). The main operational areas of products belonging to the first group:

- in refrigerators;

- in communications that carry out air conditioning.

The maximum working temperature for the first group reaches +95 ° C, however, experts do not recommend using such products at temperatures above +80 ° C.

The second group includes parts whose maximum operating temperature reaches 100 ° C. Such products are considered universal and are used in the installation of internal as well as external pipeline structures.

Helpful information! The second group of pipes made of chlorinated polyvinyl chloride is highly resistant to mechanical stress, which significantly expands its operational area.

Options for the use of CPVC pipes

The most popular such pipes in the installation of pipeline structures for various industrial enterprises. As a rule, in such communications, the pressure reaches a fairly high point. The strength limit of chlorinated PVC pipes for water supply is an indicator of 70–80 MPa, which equals 70–80 atmospheres. The high thermal stability of these products, combined with self-extinguishing properties, allows them to be used as elements related to automatic fire extinguishing systems.

Such products are great for transporting aggressive chemicals. Moreover, they are resistant both to alkaline compounds and to acids, do not react with food products, which allows them to be actively used in the food industry. At food production pipelines from CPVC can transport juices, wines, milk, etc.

The heat resistance of their chlorinated polyvinyl chloride products allows their use not only for cold water supply, but also for hot water systems, as well as for heating pipelines. Due to the low coefficient of thermal conductivity, the overall rate of heat loss in the heating structure is reduced.

Features of the installation of CPVC pipes

Chlorinated PVC pipes are mounted in several stages. Consider these steps:

- Preliminary stage;

- Pipe cutting.

- Assembly of joints.

1. The preliminary stage of assembly. First, you need to calculate the number of pipes and fittings to them. Experts recommend taking CPVC pipes with a small margin (about 10%).

After that, you need to mark up the communication. On the wall or on another surface, you need to use a marker to indicate the line for laying the pipeline, after which it is necessary to mount the fixing elements. The step length of the locking elements varies from 25 to 50 cm.

2. Pipe cutting. At the second stage, it is necessary to cut the CPVC pipes into the necessary segments. There may be a shortage of fittings at this point. In this case, the missing fittings are purchased. You can cut pipes using the following tools: a hacksaw (for metal) or through a special pipe cutter.

Important! After cutting the pipes with a hacksaw for metal, it is recommended to strip the burrs from the ends of the pipes. After this, you can proceed to the third, final stage of installation.

3. Assembly of joints. For the installation of a pipeline structure, the material for which is chlorinated polyvinyl chloride, it is necessary to use a special adhesive composition.

Consider the sequence of actions of the gluing process:

- First of all, it is necessary to apply a certain amount of glue on the inner surface of the connecting fitting, as well as on the outer surface of the CPVC pipe.

- Further, it is necessary to put the pipe into the connecting fitting and rotate it around the central axis (turning allows the adhesive composition to be more evenly distributed).

- After that, wait about 15-20 seconds and you can do the same operation with the other side of the fitting.

Thus, the installation of the pipeline structure of chlorinated polyvinyl chloride is carried out. The main difficulty is choosing the right adhesive composition. As a rule, glue is produced for specific brands of pipes, so experts recommend purchasing an adhesive with the same name as the pipes.