Supports for pipes are indispensable structural elements when laying various communications. These products take on the load of the pipeline, which is subsequently distributed to the supporting structures or transferred to the soil. Today, there are many varieties of pipelines that differ in the material of manufacture and technical characteristics. Each type of pipe requires different supports.

Content

- 1 What are the supports for and where are they used?

- 2 Features of supports for pipelines

- 3 Varieties of pipe supports

- 4 Materials of manufacture

- 5 Features and installation of fixed supports for pipelines

- 6 Installation of fixed supports

- 7 Features and characteristics of sliding supports for pipelines

- 8 Installation of sliding supports

What are the supports for and where are they used?

Pipeline supports perform a very important function - fixing the communication in the required position. In addition, these products exclude the deformational process of communication under the influence of temperatures. In many pipelines, vibrations occur during the transport of a particular medium. Vibration damping is another useful feature of support elements.

Pipe supports affect the reliability of the structure as a whole. Therefore, it is very important to correctly install these products so that they cope well with the tasks assigned to them.

Supports vary in appearance and purpose. The operational area of these devices is quite wide. They are used to fix such communications:

- pipeline structures at various enterprises;

- housing and communal services;

- fittings of nuclear power plants;

- fittings of thermal power plants (TPP);

- gas and oil pipelines.

The support under the gas pipe must have high technical characteristics, especially if the pipeline is laid in adverse climatic conditions. In addition, the support for the gas pipe should protect the communication from possible breakdowns in the places of its fastening.

Features of supports for pipelines

Operational safety and the necessary indicators of the tightness of various communications are ensured not only thanks to high-quality pipes, but also through the use of auxiliary equipment. Such equipment includes supports for fastening pipes.

If you turn to the relevant documentation, then you can find information about the fact that such an element as a support is not a separate building part, but is regulated as a constructive element of the communication itself. Supports perform many useful functions. Consider the main ones:

- this product protects the pipe from damage at the point of contact with the supporting structure;

- provides the correct arrangement of the pipeline in space;

- distributes loads along the entire length of the communication and facilitates their transfer to the supporting structures;

- eliminates vibrational waves, and also reduces stress in the pipeline.

Popularly, supports for fastening pipes are also called “pendants”, but this is not the correct name in all cases. The fact is that the suspension is one of the varieties of supports.Therefore, a generalization of all products of this type under this name is the wrong decision.

All supports for pipelines are divided into types depending on two main characteristics:

- installation option;

- mobility or immobility.

Supports are divided into movable and fixed, the latter are used where rigid fixation of pipes is needed

According to the installation option, two types of these structural elements of the pipeline are distinguished:

- ordinary;

- hanging products.

Note! A feature of the suspension devices is that they are mounted above the pipe axis.

Suspended models can be fixed to slabs, ceilings, etc. It is worth saying that the suspension models according to the installation option are of the movable type. The mobility of the support is a property that allows it to move along or across the axis of the pipeline. The movable supports are able to move in the two above directions, and the fixed ones differ in that they firmly fix the pipe in the required position.

Consider the two main functions that mobile models perform:

- such products transmit the force of the support reaction of the pipeline to the support structure. It is worth noting that this process should occur without changing the position of the point at which the transmission of the support reaction takes place;

- reduction of the stress coefficient in the walls of the pipeline.

Varieties of pipe supports

To date, there are several varieties of supports for pipelines, which differ in their design and purpose. Consider the main types of supports that are used in the installation of pipeline structures.

The type of support is selected depending on the type of highway and the conditions of its operation

Chassis supports. Such supports perform the same functions as the clamps and are divided into two main groups:

- mobile unpackaged products;

- fixed frameless products.

It is worth noting that the very concept of a sliding support is not comparable with a moving unpacked product. It is necessary to install movable rigid devices without tightening the clamp, which allows the communication to feel free and move in the longitudinal plane. Such models are also called clamp guides. Fixed models are mounted quite simply: tightly tightened to the base, which eliminates the movement of the pipeline structure.

Case welded. As a rule, this type of support is used in the installation of steel communications. The attachment of such a device is carried out by welding (hence the name).

Such models are considered the most convenient from the point of view of production and, in addition, differ in a rather affordable price. As in the previous case, case welded supports are divided into movable and fixed. In some regulatory documents, the movable hull weld bearing is regulated as sliding. The design of body welded fixtures may be different.

Case clamps. Such models are conventionally divided into two groups:

- with a clamp having a round shape (in this case, the metal rod serves as the material for the manufacture of the clamp);

- with a clamp that has a flat shape (made of metal strip).

Like other supports, case clamp models can be movable (sliding) and motionless. Products that have a flat clamp are used by and large for the installation of steel communications, however, in some cases they are used for pre-insulated pipeline structures. And models with a round clamp are used only for the installation of steel pipelines. One of the varieties of such supports is a towbar, which differs from others in that it has stiffening ribs.Stiffening ribs are needed to reinforce the product.

Outrigger supports. They are mounted specially for bending communications, namely, for bending. There are such varieties of supports for bends:

- bends of bent type;

- under welded bends.

Such models, from an operational point of view, are divided into: movable and motionless. In addition, such models are used to fix various fittings during installation.

Support brackets for vertical pipelines. Such models are used to secure vertical sections of the pipeline structure. By their design, they are “paws”, which are fixed by means of welding on the pipeline. Such models are based on beams or floor slabs.

Shield supports. Such models have the same appearance as the previous ones and are used when it is necessary to lay the pipeline through the wall. As a rule, such devices are motionless.

Pendants Pendants are special devices that are used to fix communication to a beam or ceiling. Depending on the design features and the method of mounting the supports on the pipe, they are divided into two groups:

- clamp;

- welded.

In addition, they can be:

- single-strand (consisting of one traction);

- double-weighted;

The movement of the pipeline, which is fixed by such devices is provided by a gimbal.

Spring blocks. These devices are mounted on various communications and perform a shock-absorbing function, distributing loads along the entire length of the pipeline and eliminating its deformation. Such a product is used as a structural element of supports or suspensions.

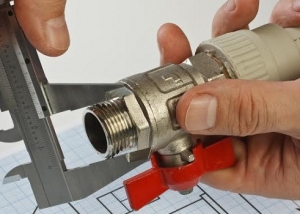

Materials of manufacture

Support for pipelines are made mainly of metal materials. This is due to the fact that such elements must have excellent strength characteristics and resistance to pressure. Installation of pipes on supports is a responsible event that requires special construction skills and knowledge, as well as experience. In case of improper installation, an emergency situation may occur, since these structural elements of the pipeline structure are under quite strong pressure.

As a rule, a material such as steel is used to produce pipe supports. Steel has a high coefficient of strength and is the best suited for these purposes. However, in addition to steel, other metals are used in the execution of these structural elements of the pipeline. Consider them:

- aluminum;

- titanium;

- brass;

- copper.

Supports made of the above materials are used for various domestic or specialized purposes. It is worth noting that the supports for pipelines must have good resistance to the harmful effects of corrosion, therefore, at the stage of production, various protective compositions are applied to their surface.

Helpful information! Various paints and enamels can act as a protective anticorrosive composition, and the surface of the product can be galvanized. Galvanized steel is highly resistant to corrosion. It is also worth noting that the application of various protective compounds to pipes, in addition to the protective function, gives them a more presentable appearance.

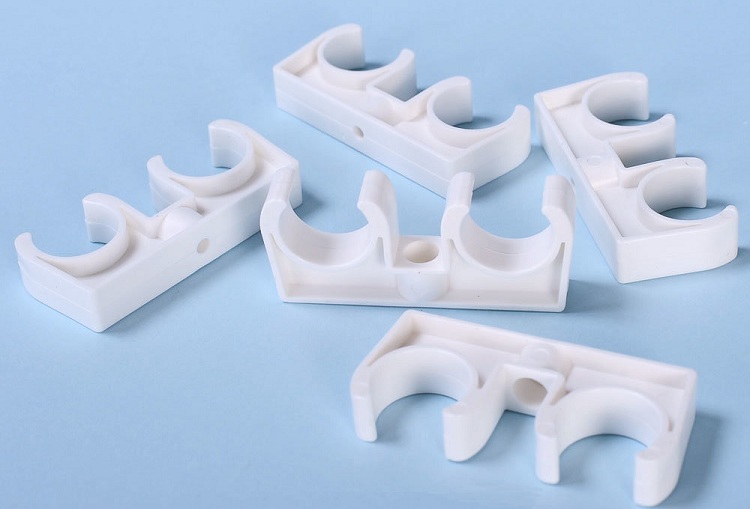

In addition, the supports can be made of various modern polymeric materials and are used in the installation of utility communications indoors. The most popular polymer for the production of these devices is considered polypropylene (PP).Polypropylene support has the following advantages:

- differs in low cost in comparison with metal analogs;

- for the installation of a polypropylene product, welding equipment is not required;

- due to its low weight, it facilitates the design as a whole;

- speeds up the process of laying communication.

The properties of polypropylene allow its use in the installation of pipelines. And also supports for polypropylene household pipes perform an insulating function, so they are not afraid of electrical influences.

In addition, it is worth mentioning another material - concrete. Concrete is used in the manufacture of support rings and their foundation. It must be noted that the production of supports is governed by state quality standards and any deviation from that described in that documentation, the production process is fraught with poor-quality products.

Features and installation of fixed supports for pipelines

Fixed supports for various pipelines are necessary for a clear fixation of communication in space. The use of such supports is aimed at eliminating pipeline shifts in the longitudinal or transverse direction.

Fixed models are used to fix pipelines mounted in two ways:

- external;

- internal (underground).

The installation of such supports is carried out by fixing them with reinforced concrete frames. Thus, in the right sections of the pipeline supporting structures are organized. The supporting structures on the pipeline are not equidistant from each other, but divide the communication into segments that have different lengths. The length of the segment depends on the features of special compensators, which are located between the fixed supports.

For external and internal laying of communications, stationary supports for pipes are widely used. In the event that the laying will be carried out by a channelless method underground, supports equipped with effective waterproofing are used. As a rule, a polyethylene (PE) sheath acts as a waterproofing. For outdoor installation of communication, a galvanized waterproofing insulator is used.

Consider the structural elements that are part of a fixed model:

- steel pipe;

- hot rolled steel sheet;

- polyurethane foam (PUF);

- special heat-resistant tape;

- galvanized shell;

- centralizer;

- polyethylene sheath.

Important! In the manufacture of fixed supports for pipeline communications, only the most durable and reliable steel grades are used.

The steel sheet, which is produced by hot rolling, is divided into three types depending on quality:

- ordinary;

- low alloyed;

- structural (is the highest quality).

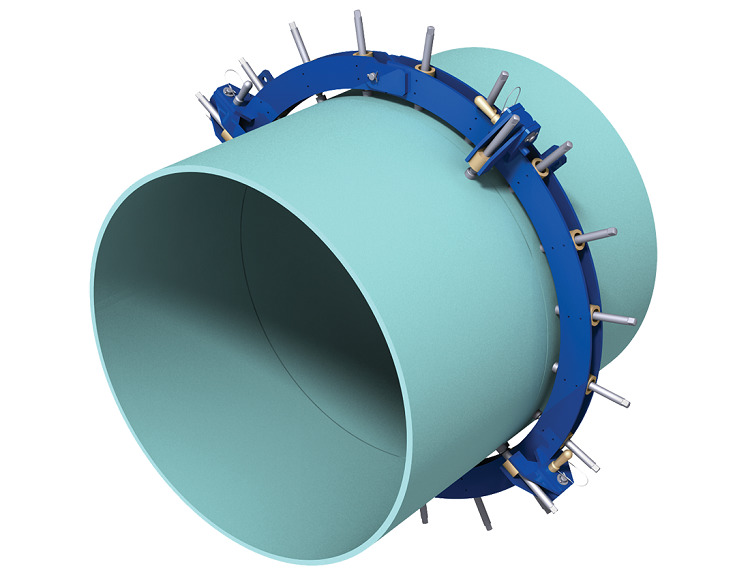

The centralizer is the structural element of the fixed support, which simplifies the alignment of the ends of the pipes before connecting them. Today centralizers are divided into two main types:

- outdoor;

- internal.

External devices center the pipe from the outside and are divided into:

- link

- eccentric;

- hydraulic jacks.

Link centralizers can center pipes with cross-sectional indicators from 57 to 2224 mm. They are characterized by excellent resistance to low temperatures. This is due to the fact that they are made from frost-resistant steel. The second option of centralizers is universal, as it is able to center pipes with any cross-sectional indicators.Hydrojack centralizers are used to center very heavy pipes or pipes with deformed areas. The force that can be transmitted through such devices is approximately 12 tons.

Internal centralizers have one important advantage - with their use, continuous welding of pipes from the inside is possible. Due to this advantage, the seams are performed more efficiently. The disadvantage of such products is that, because of their weight, it is necessary to use special equipment for their transportation.

Consider the main operational areas where fixed pipeline supports are used:

- when laying a gas main or oil pipeline;

- communications of various kinds at enterprises;

- for structures at nuclear and thermal stations.

Such supports are widely used when laying communications at low temperatures. The operation of these elements of the pipeline structure in the northern regions allows to extend the life of the pipeline.

Fixed supports are used when laying highways operating in special conditions - oil, gas, heating networks

Installation of fixed supports

The installation of such supports is carried out on pipelines of various directions. As a rule, they are immediately installed at the installation site. As mentioned above, such supports divide the pipeline into segments, and special bellows-type expansion joints are mounted between the supports. Compensators maximally protect the pipeline from deformation, which occurs as a result of exposure to low temperatures.

Fixed models using welding equipment are fixed to the platforms and fastened to the pipeline by means of fasteners. It should be noted that for more reliable attachment to these devices, special metal plates are welded (close to the ends of the clamp).

There is one important rule: between the support and the clamp, a certain clearance must be observed, which should be 1.5 mm. In addition, in order to protect the communication from corrosive influences, an aluminum sheet is laid between it and the fixed support.

Features and characteristics of sliding supports for pipelines

The sliding support for pipelines is used, as a rule, when laying communications on the surface of the earth (external method). The main function of such a device is to provide free movement of the pipeline both horizontally and vertically. In addition, an auxiliary function of such devices is the protection of the pipeline structure from abrasion.

Sliding supports are mounted on those highways whose pipes can narrow and expand under the influence of temperature

Note! Sliding supports are mounted on communications that need to compensate for seasonal temperature differences. Due to temperature changes, such pipelines expand and contract in the two above-mentioned planes.

Sliding models ensure the stability of pipeline communication and balance its movement, which occurs due to temperature fluctuations.

Consider the structural elements that are part of the sliding model:

- a base, which may be, for example, a corner;

- semicircular pipe holder (made of metal);

- special gasket;

- fasteners (nuts and bolts).

All movable supports are classified into three main types:

- hard;

- elastic;

- movable supports of constant force.

Rigid supports are divided into:

- guide bearings;

- stiff pendants;

- sliding bearings.

The guide products prevent the communication from moving down and in a certain direction horizontally. Rigid suspension brackets are devices that provide the greatest mobility of the pipeline structure.The sliding support excludes vertical downward movement. Supports of elastic type have such rigidity only when the pipe moves in the vertical direction. In this case, there is a certain pattern: the stronger the load on the support element, the further the displacement of the pipeline will be. The support of constant effort withstands the force exerted on it, regardless of the movement of communication.

In order to protect this device from corrosive effects, a special soil composition is applied to it. Soil composition for greater reliability is applied in several layers. Sometimes, instead of soil, the support can be painted with special soil enamel. And in order to achieve maximum reliability indicators, as a rule, the device is equipped with a powder or zinc coating (galvanization).

Most often, such products are made of durable carbon steel, however, if the pipeline is designed for installation and operation in severe temperature conditions, devices made of low alloy steel are used.

All sliding supports are classified into several main types according to the type of construction:

- product on brackets (fasteners);

- clamp;

- ballpoint;

- dielectric;

- roller (roller).

The roller bearing is used when it is necessary to reduce the friction force between its base and the upper part. Friction occurs when the pipeline moves. The decrease in the friction force occurs due to the structural elements of such a support - rollers.

Dielectric conflict sliding models are mainly used for pipes made from the following materials:

- carbon steel;

- mild steel.

Roller bearings are widely used in the construction of highways for pulling pipes in the horizontal direction

The insulation in such supports is made of a special material - sheet paranit. Paranit includes such components:

- rubber;

- asbestos;

- additional powder additives.

Ball sliding models are made of steel and are a specific fastener. The use of such products allows communication to move both in the longitudinal and in the transverse direction. Due to this, ball sliding bearings are used in power plants or when laying heating mains.

Installation of sliding supports

It is worth noting that when designing a communication project in which sliding supports will be used, it is recommended to determine the distance between such supports in advance. Such a calculation is made for each specific case separately. This is due to the fact that for the calculation, such characteristics are necessary as: purpose of communication, length, indicators of the pipe cross-section, material of manufacture, etc.

First of all, to calculate the distance between the sliding supports, you need to know for what purposes communication will be used. Because for pipelines that transport hot water, this distance will be less than for cold water.

Important! It is worth noting that the installation of these products is carried out before dragging the pipe into a protective casing (case).

As a rule, between the supporting device of the sliding type and the metal casing, a waterproofing material is laid. In addition, the inner surface of the pipe and the waterproofing material are lubricated with special graphite grease. This is necessary to avoid unwanted friction.

Further, clamps are fastened using welding equipment. After welding, the clamps are tightened securely. The installation of such supports is performed without the use of special equipment, which is very convenient and speeds up the work process.

In addition, when installing sliding supports, it is necessary to strictly observe all the norms and rules prescribed in the relevant documentation, as well as comply with all safety conditions.