Underfloor heating is a communication located in the floor, the function of which is to heat the living space. Before starting the installation of a warm floor, it is necessary to carry out all the necessary calculations: determine the length of the pipes, the method of installation, etc. As a rule, such a system is installed in country houses. This is due to the fact that it requires autonomous heating, which is not always present in apartments.

The number of pipes required to organize a warm floor depends on the area of the room and the method of laying communication

Content

- 1 Warm floor installation methods

- 2 The right choice of pipes

- 3 Determine the length of the pipe for the heated floor according to the scheme

- 4 Using formulas to determine the consumption of pipes on a heated floor

- 5 Calculation of underfloor heating pipes using online calculators and special programs

- 6 Features of concrete and floor installation of heated floors

Warm floor installation methods

Today, there are two main options for laying a heated floor. Consider them:

- grazing;

- concrete.

In the first case, the floor is equipped with flooring material (for example, wood). The advantage of this method is that it takes less time and effort to organize a warm floor. This is due to the lack of the need for concrete screed. The concrete method of installing a warm floor takes more time and is more labor intensive.

Laying underfloor heating in a country house or apartment is a serious event, regardless of the chosen installation option. To carry out all the necessary work, it is recommended to contact a specialist who has the appropriate construction skills. Self-assembly of such a floor is quite problematic.

Before starting work, it is also recommended to decide on the option of laying contours. There are two main ways to lay them:

- the snake;

- snail.

Laying the contour with a snake, as a rule, is carried out in cases where it is necessary to organize floor heating in a room that does not differ in the correct shape and has small dimensions. Snail laying of the contour is ideal for spacious rooms that differ in ideal proportions and have the shape of a square or rectangle.

The method of laying the pipe largely depends on the shape of the room, which is planned to be heated in this way

The right choice of pipes

Pipes, which are used for installation of water floor heating, must comply with all necessary standards and requirements. Consider the basic requirements that pipes must meet in more detail:

- they must be reliable and have a long operational life (at least 50 years);

- they must be resistant to harmful corrosive effects;

- communication of such structural elements must be resistant to temperature extremes;

- pipes for the organization of underfloor heating should be resistant to aggressive chemical compounds and pressure drops;

- each circuit related to heating communication should consist of one segment. This is necessary in order to avoid unwanted leaks.

Note! Leaks can occur not only at the joints of pipes, but also in places of bends. Typically, this occurs if the pipe material does not have the necessary coefficient of elasticity.

Consider which pipes are most in demand for organizing a floor with water heating:

- metal (steel and copper);

- metal-plastic;

- polymer.

From polymer products, polypropylene (PP) pipes and parts made of cross-linked polyethylene can be distinguished. Such polymer products have the highest strength characteristics and that is why they are suitable for organizing underfloor heating.

For the organization of a warm floor, it is strictly forbidden to use cast-iron products. Steel and copper alloy products are considered the most suitable for these purposes, however, because of their high cost, they are not used as often as polymer analogues. Polypropylene products also have one significant minus, namely: their minimum pitch is 32 cm, which in most cases is unacceptable.

The most suitable for the organization of a water heated floor, taking into account all the above circumstances, can be called products made of durable cross-linked polyethylene, as well as metal-plastic products. The diameter of the pipe for underfloor heating is also an important parameter and is determined depending on the specific case. The diameter of the pipes for a warm water floor can be: 16, 18 and 20 mm.

After selecting the necessary material, you can start calculating the number of pipes that will be used to organize this floor. In order to calculate how many pipes are needed to heat a room, you can use one of three methods:

- calculation of the number of pipes for underfloor heating according to the scheme;

- use a special formula;

- use an online calculator or a computer program that calculates the pipes for organizing a warm floor, after entering all the necessary data.

When calculating the amount of materials, it should be remembered that the pipes should be evenly distributed throughout the room so that all parts of the room are heated equally

Determine the length of the pipe for the heated floor according to the scheme

This method allows you to calculate the length of the pipe for laying underfloor heating according to the wiring diagram. Let us consider in stages this method of calculating the length of communication:

1. First of all, it is necessary to determine the method of installation of communication. There are three options for laying pipes: a single snake, a double snake, a snail.

In the first case (after the communication enters the room), the communication arrangement is performed as a sinusoidal curve. A single snake is a good option for small rooms. This is due to the fact that this method of installation is not able to provide sufficient heating for large rooms.

A double snake is an option for laying pipes, which takes into account their alternate location in the floor. This difference allows for uniform heating of the floor surface. In turn, the snail laying of the pipeline is carried out in a spiral, which allows for floor heating around the entire perimeter. Warming up occurs with the same intensity.

2. At the second stage, it is recommended to prepare the gasket directly. To do this, you need to make a drawing of future communication using graph paper. In such a drawing, parameters such as: mounting option, pipe pitch should be taken into account.

Important! It is very important to remember that when drawing up a detailed drawing of a heated floor, you must strictly follow the selected scale. Otherwise, the chart will contain errors.

Using formulas to determine the consumption of pipes on a heated floor

The use of special formulas for calculating underfloor heating pipes is also a common method that allows you to determine their required length in a particular case. Consider this formula in more detail:

L = S / N x 1.1 + P, where:

L - directly the length of the floor heating pipe; S is an indicator indicating the area of the room in which pipes for a warm water floor will be laid; N is an indicator that indicates the distance between the pipes in the corners; 1,1 - coefficient indicating losses; P is an indicator that indicates the distance from the beginning of the floor to the heating equipment. This parameter is calculated in meters. The loss index, which is 1.1, is a standard value, regardless of the method of laying the communication, as well as its manufacturing material.

Consider the basic rules for determining the area of a room (S):

- calculate the length and width of the room, and only then multiply these indicators;

- after obtaining the total area of the room, you need to calculate the surface area occupied by the corresponding furniture. The calculation is carried out in the same way as in the case of the total area. The resulting figure is deducted from the total area of the room;

- the distance from the walls of the room to the communication of the warm floor should be 200-300 mm. This is the required distance for a special damping tape.

Calculation of underfloor heating pipes using online calculators and special programs

There is another method of calculating pipes on a heated floor - using a calculator. Such calculators are located on various specialized sites on the network, so their searches are not difficult. All that is needed to find an online calculator is to write the corresponding query in the search line. The main advantage of using an online calculator for pipe calculation is that you can determine the required communication length in the shortest possible time.

When calculating the area of a room, it is necessary to take into account that the pipes will not fit close to the walls

In turn, the use of specialized programs for calculating pipes for a water floor heating allows for more accurate calculations. This is due to the fact that such a program requires the input of more data.

Helpful information! On the Internet you can download not only paid programs (for example, SketchUP), but also free products that are in the public domain.

Consider the list of basic parameters that are necessary for calculating pipes in an online calculator or a special program:

- room length;

- the width of the room;

- variety of pipes;

- option for laying communication;

- pipe pitch parameters;

- an indicator of the thickness of the coating layer.

Carrying out such a calculation is a simple and quick method that allows you to determine the amount of pipe material that is required for laying a warm floor in a room.

Features of concrete and floor installation of heated floors

A concrete version of laying a warm floor is quite common and is simple. The principle of such installation is that the acquired pipes are laid along the general contour, after which the resulting structure is poured with a cement screed. This method of laying underfloor heating is performed without the use of heat energy dividers.

In order to perform a warm floor using this technology, it is first necessary to divide the area of a particular room into small segments. The number of such segments, as a rule, depends on the geometric parameters of the room in which the installation of underfloor heating will be carried out. It is important to remember that the aspect ratio of the contours should be 2: 1. Compliance with this rule will avoid undesirable deformation of the concrete screed, which occurs due to temperature differences in the pipes.

It is mandatory to lay the heat insulator on the rough floor. This procedure will avoid undesirable heat loss during operation of the heated floor.In order for the heating of such a floor to be carried out upward, it is necessary to choose the correct heat insulator, as well as to perform the exact flow rate of the pipe to the warm floor. Experts recommend the use of foam material as thermal insulation. Moreover, the thickness of the foam should in no case exceed 15 cm. A more accurate calculation of the thickness of the insulating material is done individually, since for this it is necessary to take into account the characteristics of a particular room.

Further, after laying the insulating material, it must be covered with a film of polyethylene. A polyethylene film is needed to organize waterproofing. Next, along the perimeter of the room, a damper tape is installed, which dampens the expansion of the concrete screed with temperature fluctuations.

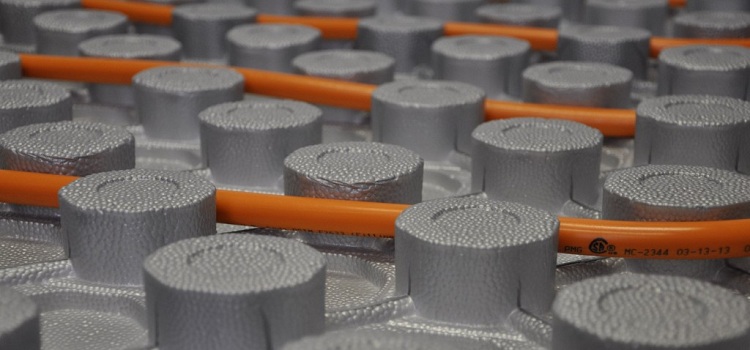

After the above work, the insulation layer is reinforced and the pipes for the underfloor heating are laid directly. A standard option for reinforcing insulation is a metal mesh with a diameter of rods up to 5 mm. The standard cell sizes in such a grid are 150x150 mm. Installation of water heating is carried out only after the necessary calculations and the choice of the method of laying communication. It is important to remember that the distance between the pipes in the structure should be no more than 30 cm (the exception is the PP part). The finished pipeline must be fixed to the reinforcing mesh. Fixation of the pipeline is carried out using clamps. At points that are expansion joints, the piping must be fitted with corrugated protection.

Note! The approximate length of pipelines, as a rule, is 70 m, and the maximum length should not exceed the figure of 90 m. If the maximum length of the heated floor pipe is exceeded, problems with the pressure in the system are possible.

How many pipes are needed per m² of underfloor heating? As a rule, approximately 5 m of pipes fall on 1 m² (if the distance between them is 20 cm). Another important rule that must be remembered when laying a warm floor: at the outer walls of the room it is necessary to reduce the step size of the pipes. This is due to the fact that the heat loss at the outer walls is significantly higher than in other places of the structure. Otherwise, a thermal drop can occur.

The final step of laying communication for a water-type warm floor is crimping. Such an operation is performed under operating pressure for 24 hours and is necessary, since it allows you to identify defects in the underfloor heating system. Further, the concrete screed is poured and the floor is finished.

A solid installation method does not imply such labor costs as in the case of installing a concrete screed. The essence of this process is that in special grooves for plates made of aluminum material, plates made of polystyrene are installed. This design includes red and blue pipes. Reds are used to supply heat, and blue are returnable. The organization of flooring is very simple: the necessary material is mounted on top of the pipes.