A warm floor is a structure consisting of pipe segments along which the heat carrier moves and various coatings. The heat carrier is water, heated to the desired temperature. The heat source in this case is the central heating system or autonomous equipment (for example, a boiler). The most preferred option is to connect the pipeline structure to the boiler, which operates due to gas processing.

Pipe laying for the “warm floor” system can be carried out in different ways, and each of them requires careful calculations

Content

The advantages of water heating

Laying pipes for underfloor heating is a serious event, which includes a number of important processes. A properly designed system is able to provide high-quality heating of the living room. The main advantages of using this communication are:

- a wide selection of tools and materials that are located in different price categories;

- installation of heating in the floor allows you to maintain the correct microclimate inside the living room;

Note! Such communication is hygienic. Unlike conventional heating systems, underfloor heating does not contribute to the spread of dust in the room.

- this design is economically feasible, as it produces uniform space heating;

- long service life with proper installation and normal use;

- the autonomy of such a system is another plus. Maintaining the required temperature is done automatically, without the intervention of the owners of the house or apartment.

Pipe Tips

Today, for the organization of underfloor heating, you can use several types of pipes, which differ in material, however, are suitable for closed laying. The most popular for these purposes are products made from:

- metal plastic;

- crosslinked polyethylene;

- copper.

The most practical and easy-to-use material is pipes made of cross-linked polyethylene, most of the heated floors are mounted precisely from them

Laying pipes from a metal plate for a warm water floor is a favorable solution. This is due to the fact that metal-plastic has unique properties that are excellent for organizing floor heating. The main advantages of pipes made of this material are:

- ductility, which allows bending of the pipeline during installation;

- resistance to corrosion;

- good strength characteristics, which are achieved due to the intermediate aluminum layer;

- simplicity of laying, which allows you to easily lay a warm floor from plastic pipes with your own hands;

- heated floor made of plastic pipes different democratic value.

Cross-linked polyethylene communication is characterized by rather high strength characteristics, is resistant to low temperatures, and is also easily repairable. However, they have some disadvantages, among which:

- unable to hold the required shape (straightened as a result of the fact that they are affected by high temperatures);

- difficult to install.

A pipeline made of copper is a rather expensive option. The use of products from this material requires the organization of additional protective measures when laying communication in the screed.

Water-type floor heating tips

Before acquiring tools and materials for organizing heating communications in the floor, it is necessary to determine the future scheme of the pipeline and calculate it. The pipe laying scheme for a water floor heating is performed as a drawing, which takes into account the location of the contours. This is necessary in order to simplify the repair work in the event of a breakdown of a particular communication element.

The diameter of the pipe is an important parameter that is associated with determining the length of a particular section of the heating system

Helpful information! The area for laying the underfloor heating should correspond to the free space in the room. That is, pipes are laid in those places where there is no furniture or sanitary equipment.

Rules that will help you calculate future communications for floor heating:

- the length of the circuit, which has a cross-sectional index of 16 mm, should not be higher than 100 m. In turn, a circuit with a cross-sectional index of 20 mm should have a length of not more than 120 m. Such restrictions are necessary, since when a certain size of the circuit is exceeded, the pressure decreases in system;

- the difference between the lengths of several contours should be minimal;

- as a rule, large rooms are divided into several circuits;

- if the pipeline in the floor is equipped with sufficient insulation, then its step index should be 15 cm. In cold regions of the country, where the temperature in winter may drop below -20 ° C, it is recommended to reduce the communication step to 10 cm;

- the fifteen-centimeter step takes into account a certain flow rate of pipes per 1 m² (approximately 6.7 m of pipeline). At a ten-centimeter step, the consumption of pipe elements per 1 square meter is about 10 m;

- to determine the heat carrier flux density index, it is necessary to use the following equation: the total heat loss rate of the room, measured in watts, must be divided by the pipeline laying area (excluding indentation from the walls);

- to determine the average temperature indicator in the system, it is necessary to measure the temperature at the inlet to the circuit and at the exit from the return line, after which add up these two indicators and divide by 2;

- the maximum temperature of the water transported through the heating communication pipes of this type should not be higher than 55 ° C;

- the length of the circuit is calculated as follows: the active heating area is divided by the step of laying communication. In this case, the active area is calculated in square meters, and the laying step is in meters. To the resulting figure, you must add the size of the bends and the distance to the collector device.

When calculating the frequency of the pipe laying step, the type of room, heat loss in it and the climate of the region as a whole are taken into account

Laying scheme for pipes for water floor heating

There are several popular schemes by which you can install this pipeline structure. All of them differ in their features and require compliance with specific nuances. The choice of scheme depends on:

- the amount of material that will be spent on installing this communication;

- indicator of heating the room.

Today, there are 3 main schemes for installing a pipeline in the floor:

- "Snake";

- spiral;

- combined.

The first option for installing the pipeline in the floor is the most common. This is due to the fact that the organization of such a pattern does not require large labor costs and with the simplicity of designing a "snake".This method is most suitable for rooms in which heat losses are excluded, for industrial premises requiring uninterrupted heating. Of the minuses of such a stacking scheme, it can be noted that temperature differences can be observed at individual points of the system. The presence of temperature differences occurring at different points of such a system, as a rule, leads to the fact that its individual sections exceed the permissible temperature value, which is indicated in building codes and regulations (SNiP).

Important! According to SNiP, the maximum constant temperature indicator for floor coverings heated by means of water communication is +25 ° C, and periodic - +32 ° C. These values apply to dwellings.

In order to minimize the uneven heating of the underfloor heating in its different areas, experts recommend that you carefully consider the choice of power of the heating structure. It is important to remember that the power of the heating communication made according to this scheme should not exceed 80 W / m².

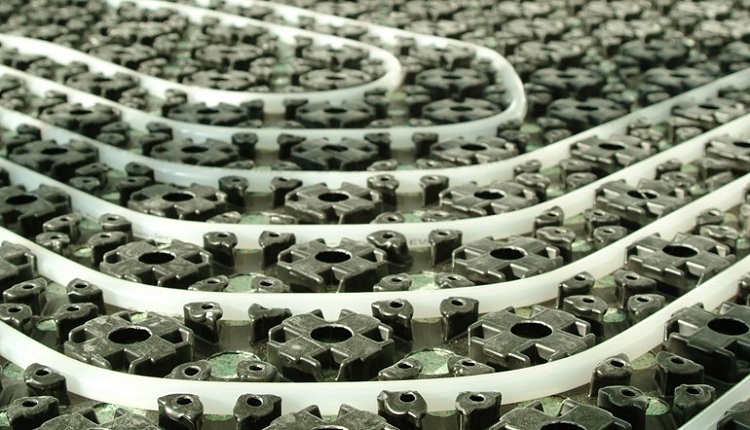

Laying pipes for underfloor heating can be done in another way. The second common way to install heating communications in the floor is called "snail" or spiral. Spiral laying of the pipeline is a more complex method and requires more careful preparation of the drawing. The main advantage of this installation method is the uniform distribution of heat. This is due to the fact that the forward and backward sections of the structure in the spiral pattern are arranged alternately, due to the cement screed, which is located above the communication. The permissible thickness of the cement screed ranges from 3 to 5 cm.

The combined scheme for laying underfloor heating pipes differs in that it combines both of the above methods. As a rule, such a scheme is used for laying pipelines in rooms that have a large area. For such rooms, a combination of patterns is the only way to organize uniform floor heating. Pipes in large rooms are laid “snake” at windows, doors and walls, and spiral laying of the pipeline is carried out in the central zone.

Pipe laying step for underfloor heating

The pipe laying step is the distance between adjacent turns of the heat circuit laid on the floor. The distance between the turns of communication is directly proportional to the indicator of the cross-section of the pipes. Thus, a large pitch is not used for pipes that have a small diameter, just as a small pitch is not used for large communications. Ignoring this rule leads to the formation of critical zones in which the temperature is much higher than the permissible one, or, on the contrary, “thermal voids” appear.

The distance between the pipes of small diameter should not be large so that the floor heating was as uniform as possible

The step length of the warm floor pipes depends on the index of the cross-section of the pipeline and can vary in the range from 5 to 45 cm. The most common values for this indicator today range from 15 to 30 cm. An increase in the step of laying warm floor pipes requires raising the temperature in the system . This is necessary in order to avoid the formation of cold zones (and vice versa). The step value depending on the heat load is indicated in table No. 1.

Table 1

| The indicator of thermal load, W / m² | Step cm |

| 48–50 | 30 |

| 80 and more | 15 |

When installing a heating structure of this type in a room with a large area and high ceilings, the pipe pitch should be from 20 to 25 cm. The communication material is also affected by the material from which the pipes are made. This is due to the fact that different materials have different coefficients of thermal conductivity.

Choosing a method of laying pipes for underfloor heating

The method of laying pipeline communication in the floor depends on which base will be used for laying pipes. The main ways of laying the floor with your own hands:

- using reinforcing mesh as the basis;

- on a heater;

- on heat-insulating mats.

In the first case, you must immediately dock the floor heating pipe with the manifold. Next, fasten pipes to the reinforcing mesh. Fastening of the floor heating pipe to the grid is carried out using polymer clamps. The calculation of the number of clamps is quite simple: on 1 meter of communication, on average, two such fasteners are required. The first clamp is fixed at the point of primary contact of the pipeline with the reinforcing network. Then the pipeline is led to the desired course, which in most cases is the edge of the wall, and the laid pipes are fixed with a second clamp.

Note! It is very important to maintain the correct distance from the wall to the end pipe. The distance in this case should be at least 10 cm, otherwise there is a possibility of damage to the pipe during construction work near the wall.

The next step in laying water floor pipes using a reinforcing mesh is to deploy the pipeline to the corner of the loop. First of all, it is necessary to take care of the fastening for the underfloor heating pipes at the points of their bends and turns. After fixing the entire circuit, a return to the collector device occurs. After fixing the circuit, it is recommended to equip it with additional fasteners for floor heating pipes, which are carried out in increments of 70-100 cm.

It is recommended to bend pipes very carefully to exclude the possibility of crushing them. For pipeline segments of different materials, there are various devices that allow fast and safe bending. To exclude the possibility of overheating of pipes near the collector device, as a rule, they are placed in special corrugated tubes that retain heat.

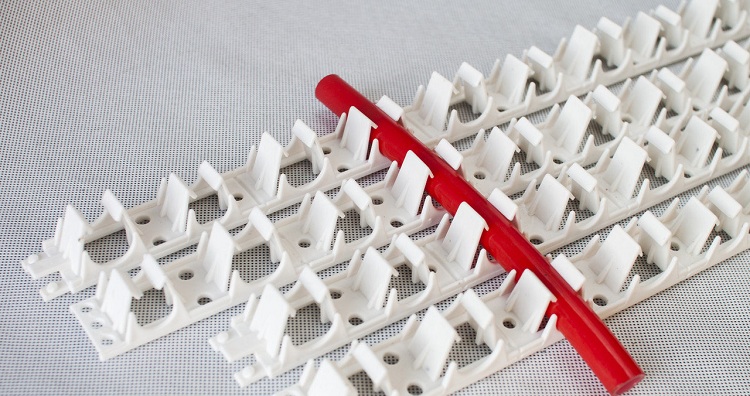

Laying metal-plastic or other heat-insulated floor pipes on the insulation (without reinforcing mesh) is performed using special strips that are easy to purchase in any specialized store. The fixation of such strips to the insulation is carried out using special brackets or using self-tapping screws. Fasteners can be combined. This method of laying communication for floor heating is most suitable if the installation of pipes is carried out by a "snake".

Planks are set in rows, between which, as a rule, a certain distance is maintained (1 m or more). The pipeline is quite easy to fix in such a bar, as it is equipped with a special groove for this. Pipe pitch is regulated by a large number of grooves that fix the communication.

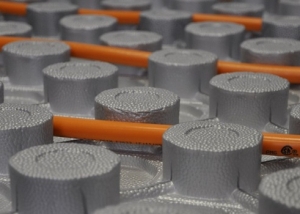

Installation of the pipeline on heat-insulating mats is quite simple. This is due to the fact that the use of mats reduces labor costs and speeds up the installation of this communication. The distance between the bosses, which are part of the mats, is approximately 5 cm, which is very convenient for regulating the pitch during the laying of the underfloor heating pipes with your own hands. Experts recommend that you be careful when cornering, as you can break the boss, so you need to carefully lay the pipes at these points.