When installing a heating system in a private house with your own hands, you can effectively use pipes from various materials. Which ones are best suited depends on the specific network requirements and the conditions for their use. Each product has its own shortcomings, features, positive qualities, technical and aesthetic characteristics. Metal-plastic pipes for heating deserve special attention.

Metal-plastic pipes for heating is one of the best options, as they are durable and easy to install.

Content

Product design

Design features of metal-plastic communications allow them to be put on heating. The inner layer is made of special plastic - a modification of polyethylene with increased strength. It does not oxidize and does not accumulate salt on the surface due to a roughness of only 4 * 10-3 mm In addition, this polyethylene is very heat resistant.

A special composition for joining plastic and the next layer of metal is characterized by high adhesion to both materials. The central structural element is aluminum, which provides hydraulic resistance to the product. The technology of its manufacture gives the metal special plasticity while maintaining strength characteristics with a thickness of 2-3 (* 10-1) mm.

Note! The smaller the thickness of the aluminum layer, the faster it will respond to temperature changes.

Then another glue layer and the outer plastic layer are applied. The metal is protected on both sides by the polymer and does not experience negative external influences.

Plastic pipes are a multilayer product, the inner and outer surfaces of which are coated with polymer

If metal-plastic pipes are placed on the heating system, then with proper assembly it will last without fail for a long time. Many firms make products of this type, including Valtec, Uponor, Rehau, Henco, Sanha, Kermi and others.

Important characteristics of metal products

For heating, a pipe is selected based on its operational characteristics. According to regulatory documents, communications are issued with an outer diameter of 0.16 to 0.63 (* 102 ) mm with a wall thickness of two to three millimeters.

Whether it is possible to put a metal-plastic pipe for heating depends on the temperature of the coolant used in the house. Such products can withstand a constant load of 95 ºС with a permissible short-term increase to 110 ºС. At minus 40 ºС they freeze.

The thickness of the aluminum layer of metal-plastic heating pipes is 190-300 microns. Communications are characterized by a working pressure of 1 kPa at a temperature of 95 ºС and 2.5 kPa at 25 ºС. The destructive pressure level for a metal-plastic pipe for heating is 8.0–9.4 kPa (at 20 ºС). She is not able to let in air.

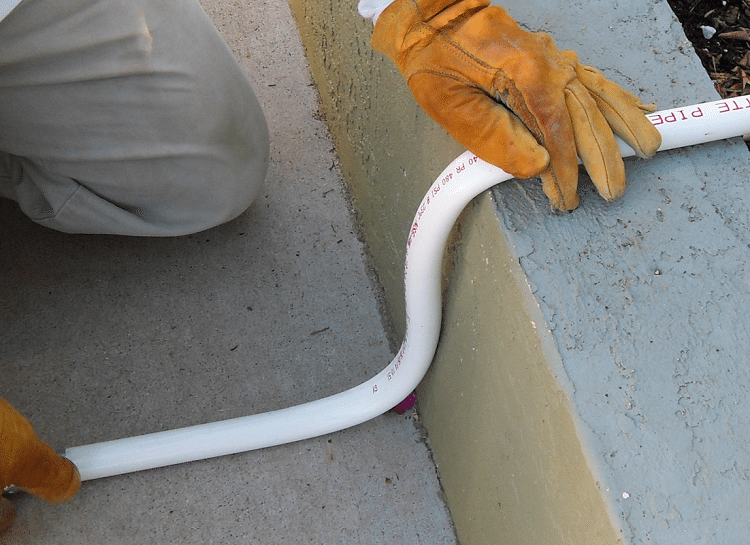

Having good technical characteristics, a metal-plastic pipe for heating has the ability to bend. The radius depends on the diameter and when bending with your own hands ranges from 8 to 12.5 cm. If you need to change the direction of communications in space, it is better to apply pipe bender. In this case, the radius is from 4.5 to 9.5 cm.

The thermal conductivity of the pipe for heating (metal-plastic) is 0.43 W / (m * K).

Disadvantages and positive aspects of products

Before deciding whether it is possible to use a pipe (metal-plastic) for the heating system in the house, it is important to better study their shortcomings and positive qualities. Of the latter, there are:

- environmental cleanliness;

- good compatibility, allowing to connect metal-plastic pipes with metal;

- resistance to the formation of various deposits in the form of stones and rust;

- the ability to preserve any form of those that are attached to them when bent;

- the possibility of organizing heating with your own hands from plastic pipes without involving many tools;

- minimum amount of waste;

- flexibility that allows you to organize the wiring of metal-plastic pipes with your own hands with fewer connection elements;

- good sound insulation, antistatic and maintainability.

The indisputable advantage of using such pipes in a private house is their throughput, which is 30% higher than that of analogues made of steel.

Metalloplastics pipes are destroyed by ultraviolet radiation, so they are best used in closed systems, such as underfloor heating

However, we must not forget about the shortcomings. A metal-plastic pipe for heating needs high-quality insulation. Although it is suitable for outdoor installation, the product will burst when it freezes with water inside. Also, metal plastic can not be placed in places of direct exposure to ultraviolet rays.

Note! If it is necessary to use a hidden installation of communications in the house, it is forbidden to make connections with threaded fittings.

Please note that metal pipe fittings have a slightly narrowed section. This leads to a slight decrease in the throughput of the pipeline.

Installation of heating from plastic pipes

Do-it-yourself installation of heating in a house made of metal-plastic communications is convenient and simple. For joining, you can use press fittings, as well as threaded connections. Which ones to choose is up to the master to decide depending on his skills and the availability of tools. Installation in a private house of heating with plastic pipes can be divided into several stages.

With the help of scissors for cutting metal products, a part of the pipe is cut, which corresponds to the required dimensions and length. It is not recommended to use other tools for cutting, since they can damage the protective coating of the pipe, which will lead to leakage in the future.

In the next step, sharp edges are removed at the edges and inside the product. Such actions will help to avoid damage to the sealing ring and to obtain insufficiently tight connections when installing communication on the fitting. To do this, you can take a round file designed for metal.

Press fittings are a reliable option for connecting MP pipes, but it requires the use of special tools

Sealing is carried out with an elastic band mounted on the fitting fitting. In order not to damage it during installation, the pipe should be flared with a calibrator. Next, a clamping clamp and nut are put on the product. At the last stage, the final clamping of the elements is carried out after their preliminary alignment.

How to connect plastic pipes with metal

Since polymer communications are very popular today for use in various systems, it is not uncommon for the repair and construction work to require the connection of metal pipes with metal-plastic ones.As practice shows, such actions are simple, but require accuracy and accuracy.

The easiest way to do it yourself is to use a crimp fitting. It is wound with a wrench on a metal pipe, which must be cleaned of rust.

Note! To ensure tightness, a polymer sealing tape or tow is used.

A press washer with a nut is put on the end of the metal-plastic pipe. The product is calibrated and put on a cone, which is attached to a metal product. At the final stage, the nut is twisted with an open-end wrench so that it tightly compresses the second pipe. The resulting compound is durable and tight. Important in this case is the selection of a fitting of the correct diameter.

DIY installation: basic rules

When installing a heating network with your own hands, it is important to fulfill all the requirements that will ensure the efficiency of the assembly. The nut can be tightened without applying much force until cracking occurs. It indicates the tight pressing of the clamp to the pipe.

It is also important to test the system for leaks. They suggest the creation of pressure that exceeds the working one and a half times, however, at least 600 kPa. Filling the system with water should be slow with open air vents.

It is very important to be careful when working with tools, if necessary, wear gloves. It is better to use for heating those models of metal-plastic pipes that have a certificate showing the consistency of materials with sanitary and hygienic standards.

Plastic pipes They are hardly flammable, but combustible, so you can use sand, foam or sprayed water to extinguish. They are also afraid of compression, kinks, the action of chemically active substances.

Heating systems at home can be easily organized with the help of metal-plastic communications. Their characteristics and advantages will provide high reliability, durability and network performance.