Fire hydrant is a device that connects to a water supply system and provides a convenient intake of water from it. The main function of such equipment is that it acts as a point to which fire hoses are used to eliminate various fire sources. An auxiliary function of the GHG is the implementation of land reclamation measures.

Installation, maintenance and operation of fire hydrants must be carried out in accordance with established rules

Content

Varieties of Fire Hydrants

What is a fire hydrant? These devices are indispensable during fire fighting. They take water from the water supply system, and then transfer it to the fire hoses under a certain pressure. Fire hydrant can be cast iron or steel. GHGs, as a rule, are used in suburban areas and are classified according to the installation option into two main varieties:

- devices that are located in wells. They are also called underground fire hydrants;

- elevated or non-well devices.

What are underground fire hydrants? Underground devices are the most popular and today it is they that are most often used to provide fluid for various needs. Their popularity is due to the fact that they provide an uninterrupted supply of fluid from the water supply.

Consider the basic rules for placing such equipment in wells:

- GHG installation should be carried out in accordance with state standards (GOST);

- it is allowed to install fire hydrants of various shapes and sizes;

- the device’s crane must be placed on the surface;

- the temperature of the working medium in the water supply system to which the fire hydrant is connected in the well must be above zero. Otherwise, its operation is impossible;

- the temperature of the working medium in the communication transporting cold water should be at least +5 ° C. The maximum temperature in this case should not exceed 50 ° C;

- the pressure indicators that this device can withstand should not be higher than 10 MPa;

- GHG installation in the well is carried out only in a vertical plane and nothing else;

- for reliability of fastening of the device special stands are used;

- Before starting the installation of the steam generator, it is recommended to rinse it with water from the well;

- the design of the device must take into account the bends to which it will be possible to seamlessly connect the fire hose.

Hydrants are aboveground and underground, the first are located on the surface of the earth and do not require a well

Note! If such a device is operated too often, then it needs a fire line. This line is installed around the perimeter of the well. The fire line consists of pipelines and hoses that are located around the perimeter of the necessary strategic objects.

To simplify the installation of the steam generator, as a rule, the corresponding instruction is attached to it. Such a technical document includes three main provisions:

- Description of installation.

- Connection scheme (fire hydrant schemes may be different, depending on the design features of the equipment).

- The sequence of steps during installation.

In order to study the structure of the GHG, you can familiarize yourself with the designation of the fire hydrant in the drawing. In the drawings, as a rule, all structural elements of this device are marked.

What are aboveground fire hydrants? A hydrant fireless fireman is used much less often and is a more complex (from a structural point of view) device. As a rule, such GHGs are mounted on sewer manholes, however, there are devices installed on the soil surface. To organize such water intake equipment, a source of water is required, the location of which should be nearby.

In the winter season, the above-ground fire hydrant must be drained, otherwise the water frozen inside it will render the device unusable. Many above-ground models have the function of automatic discharge of the working fluid, which is very convenient.

An underground hydrant is not as convenient as an aboveground hydrant, but it does not require draining water in the winter

Well requirements

Experts recommend contacting professionals in order to calculate the necessary parameters of the well in which the intake device will be located. However, if you wish, you can conduct all the calculations yourself. But such work is not easy and quite responsible. These basic wells put forward several basic requirements, which are worth paying attention to:

- It is not recommended to organize a very deep well. Fluid should be supplied from the well;

- there is no need to clean the water coming from the well. The main requirement in this case is that there should not be large foreign elements (stones and other debris) in the water;

- the indicator of the width of the well should be at least 80 cm. This is necessary for normal operation of the equipment;

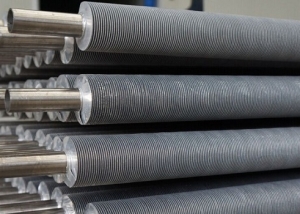

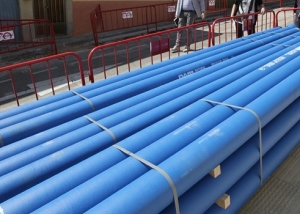

- the main material for equipping such a well is polymer pipes with large cross-sectional indicators, as well as reinforced concrete rings, which are necessary for the organization of the "skeleton" of the structure;

- it is strictly forbidden to lower the fire hydrant underground into the unfinished well, since any displacement of the soil can lead to the fact that the intake device is covered with earth.

Guided by the above requirements and performing the necessary calculations, you can install the well yourself.

Fire Hydrant Requirements

Installation of GHGs without fail is subject to certain norms and rules, which are indicated in the relevant technical documentation.

The type and number of hydrants installed at a particular facility are governed by the rules of SNiP

Consider some factors that must be taken into account before installing the water intake device:

- building height and total number of floors in it;

- liquid flow rate, which will be required to extinguish a specific structure in case of fire;

- fire hydrant throughput.

Consider the basic requirements that are put forward aboveground GHGs:

- the distance from the water intake equipment to the walls of buildings should be at least 50 m and not exceed a distance of 100 m;

- the location of the fire hydrant should be such that the distance from the edge of the roadway to the device is 2.5 m;

Important! The organization of a fire hydrant on the roadway is strictly prohibited.

- the distance to the nearest building should be at least 5 m;

- if there is an auxiliary water supply line, the installation of GHGs is prohibited;

- the cross-section of water pipes from which water will be drawn should be at least 100 mm for urban communications, and for rural communications - at least 75 mm;

- the flow rate of the working fluid with one water intake should not be lower than 15 l / s;

- the length of the fire hose must be 200 m.

In turn, underground hydrants should be installed, focusing on the following requirements:

- the distance from the axis of the intake device to the wall of the manhole must be at least 17.5 cm;

- the distance from the end of the riser to the manhole cover can vary from 15 to 40 cm;

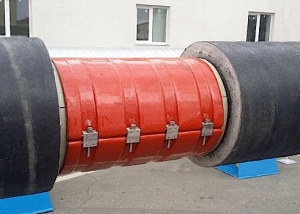

- if there is a possibility of well flooding, then the intake device must be equipped with a special non-return valve;

- a necessity is the use of supports during the installation of the steam generator. These supports prevent water leaks from the intake device.

The hydrant should be located in a place where firefighters are provided with free access at any time.

GHG operating rules

The basic rules that must be observed for the normal operation of the GHG are as follows:

- plumbing communication should provide the necessary amount of water to extinguish a fire;

- in the winter season, it is necessary to take measures to clear the GHG from ice;

- fire hydrant designation. A sign should be installed near the device, which is necessary for its quick detection;

- GHG should be freely available. The organization of any obstacles to the hydrant is prohibited;

- the device must be equipped with fire hoses and barrels.

The principle of the fire hydrant is quite simple. To use it, you must perform the following actions:

- Flip the device cover and screw the fire column to the nipple. It is very important to ensure the necessary tightness, which is necessary for a good pressure of water.

- Further, the handle of the fire column turns counterclockwise and as a result the valve opens, after which the water enters first into the steam generator, and only then it fills the fire hose.

After operation of the device, all of the above actions are performed in the opposite sequence. From GHG, it is necessary to drain the remaining liquid.

Activities that are part of the maintenance of such equipment include:

- maintaining an audit journal;

- observation of changes in fire communication and their recording;

- preventive check, repair and replacement of equipment if necessary.

Fire Hydrant Test

Testing of fire-fighting equipment is a necessary measure that determines the suitability of a device. Such checks are aimed at identifying malfunctions or failure of fire equipment. During the test, a quick start-up of the water is checked and, accordingly, the pressure in the intake device is pumped up.

Tests aimed at checking the pressure are performed if a special stand is available, as well as a pressure measuring device (pressure gauge). The accuracy class of the measuring device should be 1.5. Fire hydrant tests are carried out taking into account all the necessary regulatory documentation (GOST 15150).

Important! Fire hydrant tests should be performed at least once every 6 months.

During a GHG strength test, it is mandatory to conduct an inspection of the following structural elements of fire equipment:

- SG building;

- drain channel;

- nipple thread;

- GHG equipment is familiar.

The fire hydrant's water loss and its range are calculated at the time of maximum water consumption. After carrying out all the relevant inspections and inspection of the fire equipment, a test report of the above-ground or underground fire hydrants is drawn up. This act is transferred to the owner of the facility to which the GHG belongs and remains with him until the next test.