GOST 8639 was published in 1982 instead of the document dated ´68 and applies to cold-formed and hot-formed, electric-welded cold-worked and electric-welded seamless steel pipes with square or rectangular sections. The paper presents an assortment of such products. Technical requirements for such pipes must fully comply with GOST 13663. The numerical values of the standards from 1982 and 1968 have slight differences.

The assortment of steel pipes according to GOST 8639-82 includes products of both square and rectangular sections

Content

- 1 The use of square products

- 2 Product range according to GOST 8639-82

- 3 The values of the indicators in document 8639-82

- 4 Other possible pipe sizes according to GOST

- 5 Pipe lengths in the manufacture according to 8639-82

- 6 Limit deviations for steel square pipes (GOST 8639-82)

- 7 Limit deviations of concavity and convexity in accordance with GOST

- 8 Some changes from ´87, ´89 and ´92 years

- 9 Moments of inertia and resistance by changes from ´87, ´89 and ´92

The use of square products

The definition of the assortment of steel square pipes according to GOST 8639 (some changes were made in 92) allows us to classify products and simplify calculations of structural parameters when using them. The distribution of profile pipes is explained by a favorable combination of strength and lightness indicators.

Note! If there is a need, then it is permissible to produce products outside the range determined by GOST. In this case, the products must comply with the requirements of other regulatory documents.

They are used in the construction of enclosing structures, as supporting parts of external pipelines, metal roofs, in the manufacture of products such as frames, beams, stairs, floors. In addition, products with a square (in many cases with a rectangular) section are used in transport and in industry.

Electric-welded pipes are made from flat billets, seamless - from round.

Product range according to GOST 8639-82

The square steel pipe according to the normative document 8639 should have the sizes presented in the table.

Table 1

| Pipe wall length, * 102 mm | The cross-sectional area of the pipe, * 10-1 cm2 | Wall thickness *10-1 mm |

Weight 1 meter, kg |

| 0,1 | 3,43 | 10 | 0,269 |

| 0,15 | 5,43 | 10 | 0,426 |

| 7,71 | 15 | 0,605 | |

| 0,2 | 7,43 | 10 | 0,583 |

| 10,71 | 15 | 0,841 | |

| 13,7 | 20 | 1,075 | |

| 0,25 | 9,43 | 10 | 0,740 |

| 13,7 | 15 | 1,07 | |

| 17,7 | 20 | 1,39 | |

| 21,4 | 25 | 1,68 | |

| 24,8 | 30 | 1,95 | |

| 0,30 | 21,7 | 20 | 1,70 |

| 26,4 | 25 | 2,07 | |

| 30,8 | 30 | 2,42 | |

| 35,0 | 35 | 2,75 | |

| 38,8 | 40 | 3,04 | |

| 0,35 | 25,7 | 20 | 2,02 |

| 31,4 | 25 | 2,46 | |

| 36,8 | 30 | 2,89 | |

| 42,0 | 35 | 3,30 | |

| 46,8 | 40 | 3,67 | |

| 55,7 | 50 | 4,37 | |

| 0,40 | 29,7 | 20 | 2,33 |

| 36,4 | 25 | 2,85 | |

| 42,8 | 30 | 3,36 | |

| 49,0 | 35 | 3,85 | |

| 54,8 | 40 | 4,30 | |

| 65,7 | 50 | 5,16 | |

| 75,4 | 60 | 5,92 | |

| 0,42 | 45,2 | 30 | 3,55 |

| 51,8 | 35 | 4,07 | |

| 58,0 | 40 | 4,56 | |

| 69,7 | 50 | 5,47 | |

| 80,2 | 60 | 6,30 | |

| 0,45 | 48,8 | 30 | 3,83 |

| 56,0 | 35 | 4,40 | |

| 62,8 | 40 | 4,93 | |

| 75,7 | 50 | 5,94 | |

| 87,4 | 60 | 6,86 | |

| 98,0 | 70 | 7,69 | |

| 107,4 | 80 | 8,43 | |

| 0,50 | 54,8 | 30 | 4,31 |

| 63,0 | 35 | 4,94 | |

| 70,8 | 40 | 5,56 | |

| 85,7 | 50 | 6,73 | |

| 99,4 | 60 | 7,80 | |

| 112,0 | 70 | 8,79 | |

| 123,4 | 80 | 9,69 | |

| 0,60 | 77,0 | 35 | 6,04 |

| 86,8 | 40 | 6,82 | |

| 105,7 | 50 | 8,30 | |

| 123,4 | 60 | 9,69 | |

| 140,0 | 70 | 11,00 | |

| 155,4 | 80 | 12,20 | |

| 0,70 | 102,8 | 40 | 8,07 |

| 125,7 | 50 | 9,87 | |

| 147,4 | 60 | 11,57 | |

| 168,0 | 70 | 13,19 | |

| 187,4 | 80 | 14,71 | |

| 0,80 | 118,8 | 40 | 9,33 |

| 145,7 | 50 | 11,44 | |

| 171,4 | 60 | 13,46 | |

| 196,0 | 70 | 15,38 | |

| 219,4 | 80 | 17,22 | |

| 0,90 | 165,7 | 50 | 13,00 |

| 195,4 | 60 | 15,34 | |

| 224,0 | 70 | 17,58 | |

| 251,4 | 80 | 19,73 | |

| 1,00 | 219,4 | 60 | 17,22 |

| 252,0 | 70 | 19,78 | |

| 283,4 | 80 | 22,25 | |

| 313,7 | 90 | 24,62 | |

| 1,10 | 243,4 | 60 | 19,11 |

| 280,0 | 70 | 21,98 | |

| 315,4 | 80 | 24,76 | |

| 349,7 | 90 | 27,45 | |

| 1,20 | 267,4 | 60 | 20,99 |

| 308,0 | 70 | 24,18 | |

| 347,4 | 80 | 27,27 | |

| 385,7 | 90 | 30,28 | |

| 1,40 | 315,4 | 60 | 24,76 |

| 364,0 | 70 | 28,57 | |

| 411,4 | 80 | 32,29 | |

| 457,7 | 90 | 35,93 | |

| 1,50 | 392,0 | 70 | 30,77 |

| 443,4 | 80 | 34,81 | |

| 493,7 | 90 | 38,75 | |

| 542,8 | 100 | 42,61 | |

| 1,80 | 539,4 | 80 | 42,34 |

| 601,7 | 90 | 47,23 | |

| 662,8 | 100 | 52,03 | |

| 781,7 | 120 | 61,36 | |

| 895,9 | 140 | 70,33 |

The values of the indicators in document 8639-82

Standard 8639 gives the values of the moment of inertia and the moment of resistance for a square pipe. These values are necessary for calculating the mechanical reliability of structures.

Each product from the assortment of square pipes must have the dimensions and weight specified in GOST

Numerical values are given in the table.

table 2

| Pipe wall length, * 102 mm | Wall thickness *10-1 mm |

The moment of resistance of the pipe, * 10 cm3 | Moment of inertia, * 10 cm4 |

| 0,1 | 10 | 0,00904 | 0,00452 |

| 0,15 | 10 | 0,0233 | 0,0176 |

| 15 | 0,0305 | 0,0229 | |

| 0,2 | 10 | 0,0442 | 0,0442 |

| 15 | 0,0600 | 0,0600 | |

| 20 | 0,0723 | 0,0723 | |

| 0,25 | 10 | 0,0718 | 0,0897 |

| 15 | 0,0996 | 0,124 | |

| 20 | 0,122 | 0,153 | |

| 25 | 0,141 | 0,177 | |

| 30 | 0,156 | 0,195 | |

| 0,30 | 20 | 0,186 | 0,279 |

| 25 | 0,218 | 0,327 | |

| 30 | 0,244 | 0,366 | |

| 35 | 0,265 | 0,398 | |

| 40 | 0,282 | 0,423 | |

| 0,35 | 20 | 0,263 | 0,461 |

| 25 | 0,311 | 0,544 | |

| 30 | 0,352 | 0,617 | |

| 35 | 0,388 | 0,678 | |

| 40 | 0,417 | 0,730 | |

| 50 | 0,460 | 0,805 | |

| 0,40 | 20 | 0,353 | 0,707 |

| 25 | 0,421 | 0,842 | |

| 30 | 0,481 | 0,961 | |

| 35 | 0,533 | 1,066 | |

| 40 | 0,579 | 1,157 | |

| 50 | 0,650 | 1,301 | |

| 60 | 0,698 | 1,396 | |

| 0,42 | 30 | 0,538 | 1,130 |

| 35 | 0,598 | 1,256 | |

| 40 | 0,651 | 1,367 | |

| 50 | 0,736 | 1,545 | |

| 60 | 0,795 | 1,669 | |

| 0,45 | 30 | 0,629 | 1,415 |

| 35 | 0,702 | 1,579 | |

| 40 | 0,767 | 1,725 | |

| 50 | 0,838 | 1,966 | |

| 60 | 0,952 | 2,142 | |

| 70 | 1,004 | 2,260 | |

| 80 | 1,033 | 2,323 | |

| 0,50 | 30 | 0,797 | 1,993 |

| 35 | 0,894 | 2,235 | |

| 40 | 0,982 | 2,454 | |

| 50 | 1,130 | 2,826 | |

| 60 | 1,246 | 3,115 | |

| 70 | 1,331 | 3,328 | |

| 80 | 1,388 | 3,470 | |

| 0,60 | 35 | 1,348 | 4,044 |

| 40 | 1,491 | 4,473 | |

| 50 | 1,743 | 5,230 | |

| 60 | 1,953 | 5,860 | |

| 70 | 2,124 | 6,371 | |

| 80 | 2,257 | 6,771 | |

| 0,70 | 40 | 2,107 | 7,374 |

| 50 | 2,489 | 8,712 | |

| 60 | 2,820 | 9,869 | |

| 70 | 3,102 | 10,856 | |

| 80 | 3,337 | 11,681 | |

| 0,80 | 40 | 2,829 | 11,317 |

| 50 | 3,368 | 13,473 | |

| 60 | 3,846 | 15,384 | |

| 70 | 4,266 | 17,063 | |

| 80 | 4,630 | 18,520 | |

| 0,90 | 50 | 4,380 | 19,712 |

| 60 | 5,032 | 22,644 | |

| 70 | 5,616 | 25,271 | |

| 80 | 6,135 | 27,608 | |

| 1,00 | 60 | 6,378 | 31,889 |

| 70 | 7,152 | 35,762 | |

| 80 | 7,853 | 39,265 | |

| 90 | 8,482 | 42,411 | |

| 1,10 | 60 | 7,883 | 43,359 |

| 70 | 8,875 | 48,814 | |

| 80 | 9,784 | 53,811 | |

| 90 | 10,611 | 58,363 | |

| 1,20 | 60 | 9,549 | 57,294 |

| 70 | 10,785 | 64,709 | |

| 80 | 11,928 | 71,566 | |

| 90 | 12,980 | 77,882 | |

| 1,40 | 60 | 13,360 | 93,519 |

| 70 | 15,163 | 106,144 | |

| 80 | 16,855 | 117,983 | |

| 90 | 18,437 | 129,058 | |

| 1,50 | 70 | 17,632 | 132,244 |

| 80 | 19,638 | 147,285 | |

| 90 | 21,525 | 161,437 | |

| 100 | 23,296 | 174,721 | |

| 1,80 | 80 | 29,267 | 263,406 |

| 90 | 32,228 | 290,049 | |

| 100 | 35,044 | 315,395 | |

| 120 | 40,256 | 362,301 | |

| 140 | 44,927 | 404,341 |

Other possible pipe sizes according to GOST

Regulatory document 8639-82 for square steel products identifies several special sizes for pipes. The characteristics of such products are given in the table.

Table 3

| Pipe wall length *102 mm |

Wall thickness *10-1 mm |

The moment of resistance of the pipe, * 10 cm3 | Moment of inertia, * 10 cm4 |

The cross-sectional area of the pipe, * 10-1 cm2 | Weight 1 meter, kg |

| 0,32 | 40 | 0,333 | 0,533 | 42,0 | 3,30 |

| 0,36 | 40 | 0,447 | 0,805 | 48,4 | 3,80 |

| 0,40 | 20 | 0,354 | 0,707 | 29,7 | 2,33 |

| 0,65 | 60 | 2,366 | 7,691 | 135,4 | 10,63 |

If the steel pipe has side sizes from 0.01 to 0.12 meters and a wall thickness of 10-80 (* 10-1) mm, then it is made (according to GOST) cold-deformed.

If the dimensions of the product are from 0.06 to 0.18 meters, and the wall is 40-140 (* 10-1) mm - it is hot-deformed. Electric pipes according to 8639-82 are characterized by external dimensions of 0.01-0.1 m and a wall of 10-50 (* 10-1) mm.

Note! To calculate the mass in standard 8639 from ´82 and ´68 years, the density of steel was taken equal to 7850 kg / m3.

Also, steel square pipes (GOST 8639-82) determine the radius of curvature, which should be no more than twice the wall thickness.

Pipe lengths in the manufacture according to 8639-82

Regulatory document 8639-82 establishes the manufacture of products of non-dimensional, multiple measured and measured length.

Table 4

| Steel pipe | Length cm | ||

| measured | unmeasured | multiple measured | |

| seamless hot deformed | 400-1250 | 400-1250 | 400-1250 (with a cut allowance of 5 mm) |

| seamless cold formed | 450-1100 | 150-900 | 150-1100 (with a allowance for a cut of 5 mm) |

| electric welded | 500-900 | 150-900 | any multiplicity that does not exceed the lower limit for measuring products |

At the same time, GOST from ´82 and ´68 means that for multiple pipes their total length should not exceed the upper value for measured products. Maximum deviation of the total length up to + 1 cm. The documents under consideration have a similar assortment. Steel rectangular pipes (GOST 8639-68) are limited only by upper limit values for the length.

Limit deviations for steel square pipes (GOST 8639-82)

The product range is wide enough and the document from ´82 and ´68 gives the values of the maximum deviations of their parameters.

Note! In 8639-68 there is no division by accuracy; the standard considers the normal accuracy of manufacturing products.

According to GOST, pipes must be produced with a length restriction, which depends on the method of manufacturing the product

The data that relate to the external dimensions are shown in the table.

Table 5

| Steel pipe | The maximum deviation characteristic of precision manufacturing | |

| High | Normal | |

| seamless hot deformed | ±12,5* 10-1 % | ±15*10-1 % |

| seamless cold formed and electrowelded up to 3 cm | ±2,5*10-1 mm | ± 0.3 mm |

| seamless cold formed and electrowelded up to 3-5 cm | ±3*10-1mm | ± 0.4 mm |

| seamless cold formed and electrowelded more than 5 cm | ±8*10-1% | ±0,8% |

The maximum deviations regarding the wall thicknesses for products according to standard 8639-82 are given in the table.

Table 6

| Steel pipe | The maximum deviation characteristic of precision manufacturing | |

| high | normal | |

| hot deformed | from -15.0% to + 12.5% | from -15.0% to + 12.5% |

| cold-deformed (seamless and electrowelded) up to and including 3.5 mm | ±12,5% | ±12,5% |

| cold-deformed (seamless and electrowelded) more than 3.5 mm | ±10,0% | ±12,5% |

| electric welded | ±10,0% | ±10,0% |

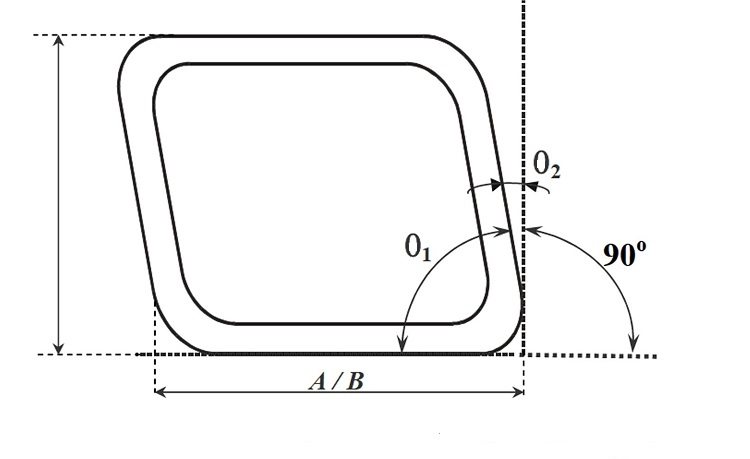

The deviation from the right angle in the transverse section should not be more than 1.5º in one direction or another. The deviation in curvature may not exceed 2 mm per meter of length.

The deviations of the rectangularity of the pipes can be calculated by determining the difference between 90 degrees and the angle O1 indicated in the diagram

Limit deviations of concavity and convexity in accordance with GOST

The maximum deviations regarding the concavity or convexity of the parties, according to GOST, are given in the table.

Table 7

| Steel pipe | The maximum deviation characteristic of precision manufacturing | |

| High *10-1 mm |

Normal, * 10-1 mm | |

| seamless hot deformed up to 5 cm | 5 | 7,5 |

| seamless hot-deformed 5-7 cm | 8 | 10 |

| seamless hot-deformed 7-10 cm | 12 | 15 |

| seamless hot formed over 10 cm | 15 | 20 |

| seamless cold formed and electrowelded up to 5 cm | 5 | 5 |

| seamless cold-deformed and electrowelded 5-7 cm | 5 | 7,5 |

| seamless cold formed and electrowelded more than 7 cm | 8 | 10 |

Rectangular and square pipes have extreme twisting deviations for high precision products. For seamless hot-formed and electrowelded, this value is 2 degrees per 1 meter. For cold-deformed indicators are agreed with the consumer.

Some changes from ´87, ´89 and ´92 years

Regulatory documents are reviewed from time to time, adjusted and corrected.

Note! In September ´92, November ´89 and June ´87 (IMS 12 - 92, 2 - 90, 12 - 87) some changes were made to GOST 8639 that complement the assortment.

The strength, reliability and stability of the structure of them directly depend on compliance with standards during production and their compliance with finished products.

Development and implementation of norms, requirements and control of the necessary characteristics of the product ensures its high quality and safety of use.

Table 8

| Pipe wall length *102 mm |

The cross-sectional area of the pipe, * 10-1 cm2 |

Wall thickness * 10-1 mm | Weight 1 meter, kg |

| 0,1 | 2,83 | 8 | 0,222 |

| 3,14 | 9 | 0,246 | |

| 3,98 | 12 | 0,312 | |

| 4,48 | 14 | 0,352 | |

| 0,15 | 4,43 | 8 | 0,348 |

| 4,94 | 9 | 0,388 | |

| 6,38 | 12 | 0,501 | |

| 7,28 | 14 | 0,571 | |

| 0,20 | 6,03 | 8 | 0,474 |

| 6,74 | 9 | 0,529 | |

| 8,78 | 12 | 0,689 | |

| 10,1 | 14 | 0,791 | |

| 0,25 | 7,63 | 8 | 0,599 |

| 8,54 | 9 | 0,670 | |

| 11,2 | 12 | 0,878 | |

| 12,9 | 14 | 1,01 | |

| 0,30 | 9,23 | 8 | 0,725 |

| 10,3 | 9 | 0,811 | |

| 11,4 | 10 | 0,897 | |

| 13,6 | 12 | 1,07 | |

| 14,6 | 13 | 1,15 | |

| 15,7 | 14 | 1,23 | |

| 16,7 | 15 | 1,31 | |

| 0,35 | 10,83 | 8 | 0,850 |

| 12,1 | 9 | 0,953 | |

| 18,5 | 14 | 1,45 | |

| 19,7 | 15 | 1,55 | |

| 0,4 | 21,3 | 14 | 1,67 |

| 22,7 | 15 | 1,78 | |

| 0,45 | 33,7 | 20 | 2,65 |

| 0,50 | 37,7 | 20 | 2,96 |

| 46,4 | 25 | 3,64 | |

| 78,4 | 45 | 6,16 | |

| 0,60 | 45,7 | 20 | 3,59 |

| 56,4 | 25 | 4,43 | |

| 66,9 | 35 | 5,25 | |

| 0,70 | 78,8 | 30 | 6,19 |

| 91,0 | 35 | 7,14 | |

| 80 | 90,9 | 30 | 7,13 |

| 105,0 | 35 | 8,24 | |

| 241,7 | 90 | 18,97 | |

| 262,8 | 100 | 20,63 | |

| 282,8 | 110 | 22,20 | |

| 0,90 | 102,8 | 30 | 8,07 |

| 134,8 | 40 | 10,59 | |

| 1,00 | 114,8 | 30 | 9,02 |

| 150,8 | 40 | 11,84 | |

| 185,7 | 50 | 14,58 |

GOST is supplemented by special pipe sizes of 0.55 cm with a wall thickness of 3 mm, a cross-sectional area of 6.09 cm2, and a weight of 1 meter 4.78 kg.

Moments of inertia and resistance by changes from ´87, ´89 and ´92

The values of the moments of inertia and resistance according to GOST 8639 in accordance with the changes (IMS 12 - 92, 2 - 90, 12 - 87) are presented in the table.

Table 9

| Pipe wall length, * 102 mm | Wall thickness * 10-1 mm | The moment of resistance of the pipe, * 10 cm3 | Moment of inertia, * 10 cm4 |

| 0,1 | 8 | 0,0079 | 0,0039 |

| 9 | 0,0085 | 0,0042 | |

| 12 | 0,0100 | 0,0050 | |

| 14 | 0,0107 | 0,0053 | |

| 0,15 | 8 | 0,0196 | 0,0147 |

| 9 | 0,0215 | 0,0161 | |

| 12 | 0,0265 | 0,0199 | |

| 14 | 0,0293 | 0,0220 | |

| 0,20 | 8 | 0,0368 | 0,0368 |

| 9 | 0,0406 | 0,0406 | |

| 12 | 0,0510 | 0,0510 | |

| 14 | 0,0572 | 0,0572 | |

| 0,25 | 8 | 0,0592 | 0,0740 |

| 9 | 0,0656 | 0,0820 | |

| 12 | 0,0835 | 0,104 | |

| 14 | 0,0945 | 0,118 | |

| 0,30 | 8 | 0,0870 | 0,130 |

| 9 | 0,0966 | 0,145 | |

| 10 | 0,106 | 0,159 | |

| 12 | 0,124 | 0,186 | |

| 13 | 0,133 | 0,199 | |

| 14 | 0,141 | 0,212 | |

| 15 | 0,149 | 0,224 | |

| 0,35 | 8 | 0,120 | 0,210 |

| 9 | 0,134 | 0,234 | |

| 14 | 0,197 | 0,345 | |

| 15 | 0,209 | 0,365 | |

| 0,4 | 14 | 0,262 | 0,524 |

| 15 | 0,278 | 0,557 | |

| 0,45 | 20 | 0,457 | 1,029 |

| 0,50 | 20 | 0,574 | 1,436 |

| 25 | 0,691 | 1,727 | |

| 45 | 1,060 | 2,651 | |

| 0,60 | 20 | 0,848 | 2,545 |

| 25 | 1,027 | 3,081 | |

| 35 | 1,194 | 3,581 | |

| 0,70 | 30 | 1,670 | 5,845 |

| 35 | 1,895 | 6,634 | |

| 80 | 30 | 2,226 | 8,905 |

| 35 | 2,536 | 10,144 | |

| 90 | 4,941 | 19,766 | |

| 100 | 5,203 | 20,810 | |

| 110 | 5,416 | 21,664 | |

| 0,90 | 30 | 2,863 | 12,882 |

| 40 | 3,658 | 16,463 | |

| 1,00 | 30 | 3,579 | 17,895 |

| 40 | 4,594 | 22,971 | |

| 50 | 5,526 | 27,630 |

The special pipe size according to GOST 55 mm has an inertia moment of 27.10 cm4 and the moment of resistance of 9.85 cm³.

Determination of the assortment of steel rectangular pipes by GOST 8639-82 allows you to quickly select the necessary product designs, as well as establish and calculate their reliability parameters.