You can’t do without supports when arranging land and above-ground pipelines. Their purpose is the perception of weight loads created by engineering communications. If you do not provide reliable fastening, it will lose strength, while the connection of the pipeline elements will become less reliable. This indicator depends on the dead weight of the structure, external vibrations, climate and so on. Supports are designed to neutralize the negative impact of these factors.

Polymer pipes are used for the installation of communications of various types and purposes, and some of them require rigid fixation.

Content

Types of supports

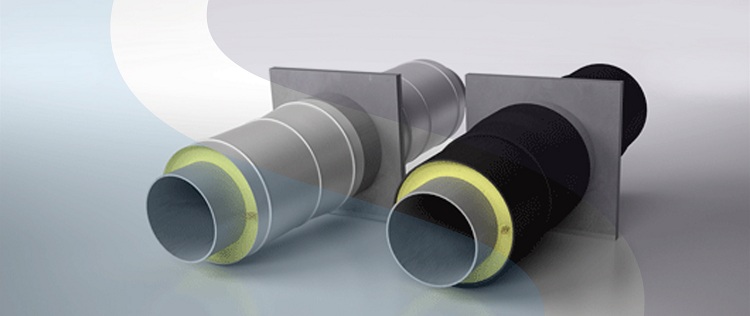

Today, for polymer pipelines, supports in polyurethane foam insulation are most widely used. These products are of the following types:

1. Fixed support for polyurethane foam pipes. It is used for aboveground and ground systems. Due to the special compensators included in the design, a reduction is ensured:

- the influence of temperature conditions;

- differences in internal pressure;

- vibrations of various types.

In addition, the support of this type performs the additional function of a heat insulator. You can meet such a construction most often in the northern administrative-territorial units of Russia, that is, where sharp temperature fluctuations are often observed;

2. Moving support. Designed to compensate for vertical loads. The movable support does not increase the stability of the pipeline and does not affect its wear.

Design classification

The structural features of the supports affect the technology of their installation. According to this criterion, these elements are of the following types.

- case welded. This type of mobile and non-moving support PPU can be manufactured in a wide variety of designs. Advantages: easy installation, affordable price.

- case clamps. They can be both mobile and motionless. In turn, such supports are divided into products with flat and round clamps. Also in this group are towing structures. They are distinguished by the presence of stiffening ribs.

On a note! I use polyurethane foam pipestXia supports with round clamps. However, they are also successfully used for steel pipelines.

- Chassis type constructions. Simply put, these are ordinary clamps. They are motionless, as well as mobile. The former are connected to the base by welding. Products of the second type provide free movement of the pipeline. Unpacked moving products received a different name - clamp guides.

- bent bends. Installation of such a product is carried out under the bend of the structure. Steep bends can be fixed and movable. They are also used as structural elements for mounting various types of equipment.

- panel constructions. Such a fixed pipe support is used to secure vertically directed sections of engineering communications. It is often mounted when the heating system branch passes through the wall.

When choosing supports, it is necessary to take into account operating features, diameter and type of pipeline.

Production and Application

Steel is used as a raw material for the manufacture of supports. If it is assumed that the pipeline will operate under normal conditions, such elements are used that are made from standard long products. When operating in specific conditions, you should choose metal supports in the foam insulation, able to withstand both high and low temperatures, characteristic of climatic conditions of the Far North.

A fixed support is made for PPU pipes according to the following technology:

- steel sheets are cut on a high-precision machine;

- then the material is cut on the guillotine;

- steel sheets are cut using tape equipment;

- elements are welded.

Steel pieces are connected by clamps. They are made on automated presses. Thanks to the use of this equipment, these elements are obtained of the highest quality.

Metal supports are used for maintenance purposes:

- gas pipeline;

- oil pipeline;

- to start the polyurethane foam heat supply pipe;

- for the operation of thermal and nuclear power plants.

Calculation of pipe supports

This procedure is performed to determine the distance between the supports. The initial data here are the strength and deflection of the trunk. Equally important is the way of laying and the parameters of the pipes. For calculations, you should use the table "Design of heating networks" compiled by A. Nikolaev.

For example, for a horizontal arrangement, the table demonstrates this calculation: at a maximum temperature of the working medium transported through the pipeline +60 ۫ С and a minimum section of the trunk section of 20 millimeters, the distance between the supports should be 60 centimeters.

Good to know! The distance of the supports from each other grows with increasing pipe diameter.

The mounting pitch for vertical arrangement is calculated according to the same principle. For example, at a temperature of +20 ۫ С and a cross section of an engineering communication branch of 40 millimeters, the distance of the supports from each other will be this - 138 centimeters. If transportation of a working medium with a temperature of +70 ۫ С is supposed to be transported, this distance will decrease to the level of 113 centimeters.

When arranging fixed supports, the schematic characteristics of thermal communications are taken into account, namely the location of structures near shut-off valves and branches of the main. As for the straight sections, here the technical parameters of the compensators between the supports are taken into account.