Plastic ventilation pipes are increasingly used to equip appropriate utilities, despite certain restrictions imposed by the characteristics of the source material. They are especially in demand at the household level, as they provide huge opportunities for the design of the premises, organically blending into the interior and not cluttering up the space.

Content

Why plastic ducts are beneficial for ductwork

To find out why plastic is readily used in the arrangement of supply and exhaust ventilation systems, let's see what requirements their components must satisfy:

- tightness;

- noise insulation so that there is no aerodynamic drone that does not meet sanitary standards;

- free passage of the working environment with a given design speed;

- maintaining the design pressure of the working environment;

- thermal insulation;

- maintaining sufficient free space in the room;

- match the interior and aesthetic preferences.

At least, for the arrangement of household ventilation, they prefer to pick up pipes made of plastic, based on the fact that:

- the effect of corrosion will not affect the performance of the system in any way due to the inertness of the material to its effect. Inevitable condensation will not lead to rust and ventilation failure.;

- they are inert to aggressive chemicals;

- the design will be durable, wear-resistant and flexible;

- antistatic properties are given to the surface, which do not allow dust deposits to form and become dirty;

- installation costs are reduced several times due to the low cost of pipes for plastic ducts;

- low roughness facilitates the passage of air masses on a smooth inner surface that does not require cleaning;

- installation is quick and easy;

- grace and lightness of a design allow to achieve a pleasant esthetic impression;

- environmental safety of the installed system is achieved, which does not harm either the environment or the health of the occupants of the premises;

- the service life is comparable with the period of use of the building without major repairs, reaching fifty or even a hundred years;

- variety of assortment, and plastic pipes for ventilation have different shapes and sizes, and fittings open up a vast field for modeling and satisfying design abilities.

The disadvantages of plastic for exhaust ventilation include exposure to fire. Therefore, it is not customary to use plastic ventilation pipes for exhaust ventilation at industrial enterprises, especially in those cases when the system needs to be routed through several fire hazardous sectors. Another drawback (however, disputed) is the tendency to accumulate dust on external surfaces than in household premises, in principle, can be neglected.But the tendency to abrasion and lack of strength - not always.

Classification of plastic ventilation pipes and systems

Plastic ducts (exhaust and supply) are distinguished by several parameters:

- application. They can be used both in residential and office premises, and at industrial facilities;

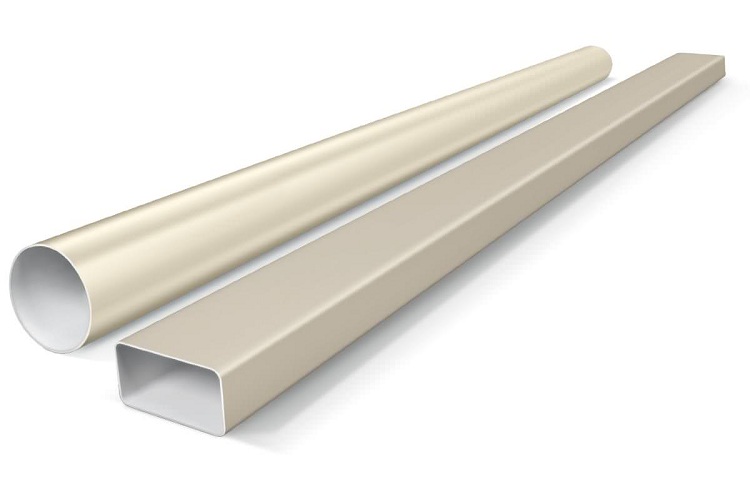

- form, which affects the possibility of hidden placement. Air ducts can be airborne (to remove fumes from the production baths), round (can cause problems with hidden installation) and rectangular (used specifically for hidden installation, in the case of installation, it is very likely that turbulences appear);

- installation method;

- throughput sizes;

- technical characteristics that take into account the pressure (minimum and maximum) and the speed of air flow.

Plastic pipes for ventilation in shape can be:

- square. Square products are considered as a kind of rectangular;

- rectangular. Plastic rectangular elements are extremely convenient for installation, as they are in close contact with any flat surface. It is customary to cope with the problem of low noise insulation by placing the structure in space above the false ceiling;

- flat. Flat elements are somewhat more compact than rectangular ones, therefore they are used in conditions of limited space for placement;

- round. They are distinguished by high bandwidth and sound insulation. They equip long routes;

- oval.

For rectangular plastic ventilation pipes, the height is 55 or 60 mm, and the width is 110-122-204 mm. Round are produced with a diameter of 100-125-150 mm. The wall thickness is considered optimal when its value is 3 mm. With a larger thickness, the bulkiness and cost of the product increase significantly, with a smaller one - the structure loses its rigidity.

There are differences in the material used to make round or flat ventilation pipes:

- polyvinyl chloride. PVC is in greatest demand for use in household systems. There are some restrictions on the use of external temperature. Falling below a five-degree mark makes the material brittle, and an increase to + 120º C is considered dangerous to human health. At + 160º С, the release of chlorine begins, which is detrimental to all living things. Therefore, installing PVC products in a sauna or near a fireplace is not worth it, but in such rooms as a kitchen or bathroom - just right;

- polypropylene. Products demonstrate the absence of hygroscopicity, excellent dielectric properties, inertness to aggressive environments and high strength. It is unacceptable to increase the temperature to + 85º C, however, this problem is solved by the purchase of pipes with flame retardants to the source material - PPS, which are more fire resistant;

- polyurethane. The characteristics are close to PVC, but the fire resistance is much higher - the limit is 280º C;

- polyethylene. PNDs are rarely used in household systems. But the products from it are excellently suitable for installation in places where heating in the cold season is not constant. Polyethylene is able to withstand sudden cooling - up to -50º C, while maintaining operability. Heating should not exceed 80º C.

In terms of flexibility, plastic ventilation pipes can be:

- rigid with a wall thickness of three or five millimeters and a width of 100-1000 mm;

- flexible (corrugated, made of polyurethane). The length of the duct from round, rectangular or square ventilation pipes, as a rule, does not exceed 15-20 m. It can be installed in a chemical laboratory at a construction site to remove smoke and polluted air.With an internal cross-section of 60-500 mm, they can be operated at temperatures from -35º C to + 90º C.

There are differences between designs by the pressure parameter in the system:

- low - up to 900 Pa;

- medium;

- high - over 2000 Pa.

According to the speed of movement of the working medium, structures are:

- low-speed - the movement of air occurs at a speed of up to 15 m / s;

- high speed.

Composition and purpose of the main and additional elements of the plastic ventilation system

The ventilation system is composed of the following main elements:

- air duct (pipes);

- extractor hood;

- pipe connection elements (crosses, bends, transitions, tees, gates), allowing the creation of a branched system;

- plugs and grilles that cover and seal the ventilation outlets. These elements perfectly cope with decorative functions;

- hatches for maintenance;

- check valves in the form of a frame with a blade, preventing reverse traction.

As additional elements use:

- filters. In a large system, they can be of various types - metal, fiber, coal, bag, etc. They purify the air and also protect the elements of the system itself;

- supply valves to ensure natural air exchange;

- fans providing air inflow and / or exhaust;

- with an anemostat - a plug covering the opening of the ventilation channel and allowing manual adjustment of the air flow.

Installations for the implementation of forced ventilation can be:

- with recuperator. The passage of exhaust and incoming air through the heat exchanger eliminates the need for an air conditioner (heat pump). They are considered the most popular;

- recirculating, mixing the incoming and exhaust air. The cost is minimal, but normal operation at low temperatures is not ensured and harmful substances are not removed;

- providing air cooling. Installed in rooms for storing food or catering;

- with air conditioning.

The fan for forced exhaust or air supply is selected depending on the size of the pipes and the length of the system

How to choose a duct

Choosing the shape and size of the pipes for the ventilation duct as the basis for the installation of the entire ventilation system, one should proceed from its main purpose, type and dimensions. Thus, it will be possible to ensure the normal operation of engineering communications.

First, a project is drawn up, taking into account the size of the room and its features, as well as all the nuances associated with the placement, installation and operation of system elements. A plastic duct should allow air to travel at speeds up to three meters per second. Using pipes with a small internal cross section to save space and to achieve an aesthetic impression, it is possible to achieve excessive noise levels during operation.

When calculating the ventilation system, two indicators of the required air exchange are used:

- Based on the number of people staying indoors. The norm for one person is 60 m3 / h.

- Given the multiplicity of the process. The volume of the premises is multiplied by a factor equal to 1 or 2 for housing, for public premises - 2 or 3.

- Pipes of the required section are selected using the formula: S = 2, 778 LV, where S is the cross-sectional area in cm2, L is the required air exchange, V is the air velocity.

You can use special programs that allow you to calculate all the parameters of the ventilation system.

The shapes of the ventilation duct have certain disadvantages and advantages.It is worth considering that in the presence of turns and branches, the level of costs for installing connection elements increases sharply when choosing a round or oval shape. If the ventilation duct is laid almost in a straight line, then the installation of oval or round pipes will cost about half as much as rectangular ones. With a flat oval shape, the resistance to the passage of air flow is significantly inferior to a rectangular one, reducing energy costs. But their cost is much higher.

Ducts with a circular cross-sectional shape have a higher throughput, but an incorrectly selected diameter can lead to increased noise

Installation

The project takes into account the number, parameters and locations of all elements of the ventilation system. After making the necessary calculations and purchasing materials, you can begin to collect and install plastic ventilation.

- Plastic pipes and connecting elements are assembled in a single system. The tightness and reliability of the joints, which will have to be subjected to sufficiently strong air pressure, should be ensured.

- Opposite walls of the room are provided with holes for installing devices to ensure exhaust and air flow.

- The assembled duct is secured with special brackets or with clamps.

- On the prepared openings in opposite walls, a suction fan and an exhaust fan are installed (with the mandatory presence of a check valve).

- The connection of the pipe for the hood and the exhaust device.

- The elements provided by the circuit, such as a filter, air heater, recuperator, air conditioner, are connected to a suction device.

- The connection of the ducts and the air supply system.

- Additionally, it is possible to carry out sound insulation, as well as thermal insulation.

The variety of the proposed range of plastic ventilation pipes, differing in shape, materials and sizes, allows you to choose the most suitable option for arranging a system for a specific purpose. This diversity is complemented by the corresponding presence of the necessary additional elements.

The system can be arranged according to your own aesthetic and design preferences. The main condition for the optimal functioning of plastic ventilation is a competent design. At this stage, it is advisable to connect a qualified specialist to carry out the necessary calculations, otherwise the costs will not produce the desired result. But the successful assembly and installation is quite possible with our own resources, since the tools needed are simple, and the fasteners are easily selected.