Pipes made of low pressure polyethylene (HDPE) have proven themselves in water supply systems and sewer circuits. Most often used to supply cold water and in gas supply systems use pressure PND pipes. For storm and fecal sewage, the optimal solution is pressureless polyethylene pipes.

Content

- 1 Methods for connecting HDPE pipes

- 2 Electrofusion fittings made of polyethylene

- 3 Advantages and disadvantages of HDPE pipes and connecting plastic fittings

- 4 Detachable connections and fittings for HDPE pipe

- 5 Brass fittings for HDPE pipe, mounting tools

- 6 Quickly fixed plastic fittings for HDPE pipes

Methods for connecting HDPE pipes

The connection diagram for pipes of the same diameter consists of two components: special welding equipment and fittings of the corresponding diameter. The method is justified in the case of laying house communications. The best option for do-it-yourself system installation - brass fittings for HDPE pipes. This is a universal solution for pipes of various diameters, and you will not need a special tool to work with them.

One-piece assemblies and welded fittings for HDPE pipes:

- Butt welding is characterized by the formation of a durable monolithic seam. Fittings are used the same diameter as the pipe, special welded equipment;

- The nesting method of welding will require the use of a different type of fittings. Warming up occurs on the inner surface of the fitting - this is the connecting plane, and on the outside of the pipe. The fitting will have an external diameter larger than the diameter of the welded HDPE pipes;

- edge welding allows the connection of pipes of any diameter with a drainage well.

For edge welding, a special electrode is used. This method is applicable only for installation of pressureless systems.

Electrofusion fittings made of polyethylene

The main advantages of fitting for pipes PND - quick and easy installation, high strength of the seam. It is easily mounted “in place”: in technological wells, trenches, niches.

Type - electric-welded fittings for HDPE pipes. Varieties:

- elbow bends. Run with dimension. 30, 45, 60 and 90 degrees;

- Coupling for PND pipe. Used to build, repair and lengthen existing communications;

- T-shaped tee. The initial stage of installation of such a fitting is identical to the installation of a sleeve for polyethylene pipes in the circuit break, then the outlet channel is connected;

- reduction transition. For the reverse feed of a part of the flow, or for reverse feed circuits, the diameters of the joints may be different;

- shoulder sleeve. This is a coupler for a polyethylene pipe, allowing you to connect to a steel pipe;

- master fittings. It can be a connecting piece, or an adapter. They are carried out by special orders, the customer provides a detailed drawing, including the purpose of the fitting.

Polyethylene couplings due to their ease of installation and low cost are the most common type of fitting.

Advantages and disadvantages of HDPE pipes and connecting plastic fittings

Chemically inert and easy to install, with low cost and a wide range of applications, plastic pipes have one significant drawback: poor resistance to ultraviolet radiation. In the manufacture of HDPE pipes, special additives, such as soot, are used to increase resistance to sunlight.

The narrow temperature range for the application of HDPE pipes - from 0 to 40 ° C - is due to the characteristics of the material. Polyethylene of low pressure and high density at room temperature is chemically inert and retains its properties for a long time.

Benefits:

- the small weight of a running meter of PND pipe and its elasticity make it easy to transport the bay with the pipe to the installation site;

- coefficient of thermal expansion of polyethylene pipes - only 3%;

- the guaranteed service life, depending on the type of pipe, allows the use of plastic pipes for about 100 years;

- the dielectric properties of the PND pipe allow it to be used as a protective box for the power supply line;

- laying in soil and connections can be made without an additional protective layer.

The advantages of such pipes are much greater than the disadvantages, so they are used in various fields of construction.

Detachable connections and fittings for HDPE pipe

To ensure a strong and reliable joining of the PND pipes and create a detachable connection without the use of special equipment and without significant financial costs is quite realistic. An installation engineer will need fittings for polyethylene pipes and a simple tool.

The most common option is a connection in which PND pipe compression fittings are used. The main advantage: there is no need to use special equipment. A pair of clamping keys is enough, and provided that the assembly steps are followed correctly, the connection will be strong and durable.

Good to know! If necessary, such a connection is easily disassembled and reassembled without loss of performance.

Types of couplings for HDPE pipes are selected based on the tasks to be solved: gas supply, heating or plumbing system.

Standard components of a compression plastic fitting:

- body. The wall thickness of the fitting body for HDPE pipes is always greater than the elements associated with it;

- clamping ring. Its function is to hold the entire structure assembly under the influence of mechanical stress, for example, when the pipe is stretched during water hammer;

- ring sealing. The only way to ensure the tightness of the connection and to maintain the possibility of dismantling without damaging the pipe;

- pressing sleeve. Allows you to fix the pipes in the fitting, without violating their geometry;

- nut cover.

The tightness of the connection may be impaired by improper assembly, if the pipes are skewed during installation, for example, in a sleeve for connecting polyethylene pipes.

Brass fittings for HDPE pipe, mounting tools

The most durable and versatile variety of fittings is brass fittings for HDPE pipes. They successfully use fittings of this type in plumbing and heating systems, and are widely used in gas pipelines and process fluid supply systems.

The working pressure of brass elements at maximum load is up to 20 bar. PND coupling with ease will withstand both temperature differences and water hammer. They do not require special skills and a special tool during assembly.

An additional layer of nickel and chromium on the brass fitting increases its anticorrosion properties and increases mechanical strength. A brilliant fitting looks respectable, chrome couplings for joining HDPE pipes look especially stylish.

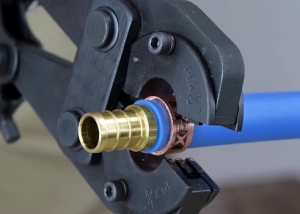

A relatively new direction in the assembly of water supply systems and gas systems is press fittings. The method of fixing the fitting to the pipe with the help of a special sleeve crimped by press pliers allows to obtain a strong and tight connection. Disassembling such a unit is possible only if the fitting is supplemented with a threaded connection.

Tools for crimping a fitting to an HDPE pipe:

- special ticks;

- pipe calibrator, often included with crimping pliers;

- pipe cutter of any type;

- measuring tool (tape measure);

- set of wrenches for tightening threaded connections.

Most of the necessary tools are always in the arsenal of any master. But crimp pliers will have to buy or rent.

Important! When buying brass fittings, you can’t save. You need to choose heavy, high-quality components with distinct, well-readable markings. The walls of the connecting fittings must be of adequate thickness, the connecting part must be strong. Good couplings for HDPE pipes have a solid, impressive appearance.

Quickly fixed plastic fittings for HDPE pipes

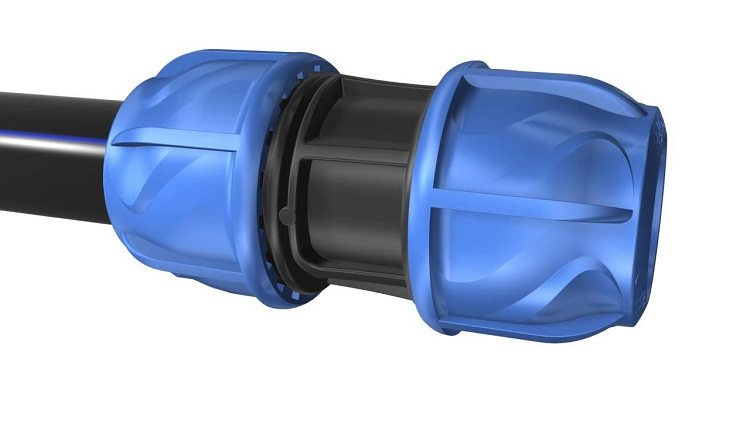

The easiest way to fix the fitting to the front pipe is called push-fit. For example, there is a coupling for pipes PND, and for its installation will not require any tool!

A design feature of such a fitting: a system of o-rings (3 pcs) and a locking grip. All that is needed is to insert a pre-measured and calibrated PND pipe section into the fitting, the connecting part will firmly fix the fitting to the pipe. Advantages: easy to disassemble, even with a simple wrench, the connection is strong and tight. The disadvantages include this moment: unevenly cut or non-calibrated pipe edge does not guarantee the tightness of the connection.

Fittings for polyethylene pipes of Italian manufacturers have proven themselves excellently. The highest quality workmanship and a multi-stage control system for finished products are the distinguishing features of quality products.