Reinforcing bracket (or wire) U- or U-shaped - a popular type of fastener. The scope of the U-shaped clamp depends on the characteristics attached to it during manufacture, determined by the material and method of execution, type, thickness and width, length of the legs. For construction and rigging, furniture, fastening cables and pipes when laying utilities, U- and U-shaped brackets (clamps) are simply necessary.

Staples and clamps of various shapes are necessary for the installation of various structures and communications from pipes

Content

Scopes and advantages of use of U-shaped brackets

The bending products made of reinforcement are inherently universal. When carrying out monolithic and prefabricated construction by them:

- constructions are pulled together;

- foundations and reinforced concrete structures are reinforced;

- reinforcing mesh are separated;

- rafters and crowns are fastened.

Note! When putting forward increased demands on the reliability of fastening, it is customary to resort to the use of a U-shaped bracket with thread.

Products without corrugation are considered more reliable, since:

- corrugation intersections can become stress concentrators, reducing the reliability of the structure as a whole;

- the presence of corrugation can turn into a rupture of the material.

The advantages of U-shaped brackets in comparison with other fasteners include:

- the ability to limit the use of manual labor by using special pneumatic tools or staplers;

- lack of need to attract a qualified specialist;

- variety of assortment, allowing selection of the necessary details for a specific purpose;

- conducting work without impact, experiencing the stability of the fastened structure;

- durability and reliability.

The use of forged U-shaped staples in wooden construction

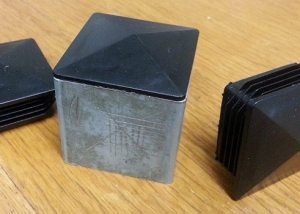

Wood, as a building material, partially regained the once lost position. For fastening various elements made of wood structures, designed for decades of operation, it is customary to use the most reliable of the U-shaped staples - forged. Forged U-shaped bracket is performed using hot forging of a smooth steel bar.

It's important to know! To make the fasteners easier to drive into the tree, their legs are turned, acquiring, as a rule, the appearance of a quadrangular cone. Notches are applied to the legs to prevent the fastener from escaping from the wooden surface under the influence of loads arising during operation.

In the manufacture of forged brackets, it is customary to slightly flatten a steel bar in the corners. This helps to maintain the necessary stiffness in places of bending of the bracket. The advantage of the forged bracket in comparison with reinforcing bracket-bending products is seen in increased strength and rigidity. Hammering the forged bracket, the builder is confident that it will not break.

The most common are forged brackets of eight to twelve millimeters in diameter.

U-shaped brackets are more convenient for fixing pipes of different materials, they are often used when laying water, gas pipelines and electrical networks

Where is the U-bolt used

U-shaped staples are also in demand. For their manufacture attracted as a material:

- metals;

- polypropylene. Such products are used to fix elements that are not very heavy. They are fastened using a large bolt integrated on one side.

- the wire.

The two-bolt bolt bracket provides reliable fixing, despite the influence of vibration. It is used in engineering equipment, laying cables and pipelines. Fasteners are pressed to the base using self-tapping screws or bolts. A single-foot bolt-bracket with additional stiffening ribs at the place of bending is in demand when laying a route full of turns, curvatures of the trajectory.

The U-shaped bolt bracket is used by attaching:

- cable, metal hose to building structures;

- hanging pipes and beams of circular cross section;

- elements of plumbing;

- rigging.

Using rigging brackets

This special kind of this fastener element, protected by a special coating, is used:

- with pin screw connections - for occasional use;

- with safety bolts - for long-term use.

Product types have a specific purpose:

- CA. They fasten chains, cables, ropes, elements of static and lifting systems;

- Sat Equipped with additional transverse elements for connecting holes at the ends. They fasten and pull rigging equipment, attach cables, etc.

- R. Loop-shaped with holes for a finger or pin. They serve on ships and vehicles, therefore, high-strength steel alloys are required for the manufacture.

The use of rigging fasteners is accompanied by certain requirements:

- the right selection, taking into account the importance of carrying capacity;

- uniformity and uniformity of the pin and housing;

- the absence of damage, defects on the surface and thread;

- complete set of safety bolt with adjustable cotter pin;

- inadmissibility of heat treatment, exposure to aggressive environments and additional bending during operation;

- load distribution along the axis.

Important! When securing with such brackets, the load must be fixed, otherwise the pin may rotate and unscrew.

The correct use of U-shaped and U-shaped fasteners guarantees their long work. But it is necessary to check the condition of the fasteners from time to time, replacing worn out elements.