Pipes made of polymer materials, every year more and more displace the usual metal products. Why? The answer is simple: plastic is more mobile, lightweight, unpretentious and cheaper. HDPE pipes - This is an excellent option for those who want to install a water supply system in a house or on a site without spending a lot of financial and time resources. Of course, installation of polyethylene products has its own subtleties and nuances, which will be discussed below.

Content

The main varieties of polyethylene pipelines

The abbreviation "PND" is usually deciphered as "low pressure polyethylene". Pipes made in full accordance with GOST can perfectly function as a water supply system (mainly cold water supply) for several decades.

The product range includes models of HDPE, designed for various economic purposes:

- Sewer pipes. This product is not intended for water supply or pressure sewer pipelines. Of these HDPE segments, only pressureless sewage can be constructed. These products are produced mainly in orange, they are smooth or corrugated.

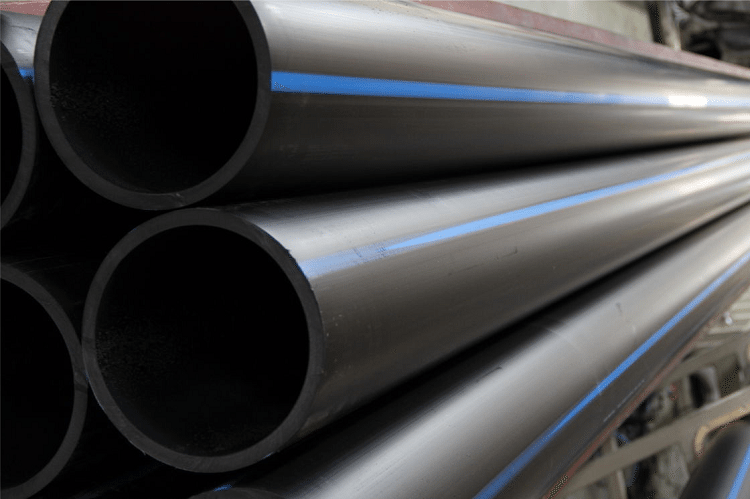

- Pipes for water supply. Strong and durable, they can work at a pressure in the range of 5-15 atmospheres. They have blue stripes on the sides. It is worth remembering that not all low-pressure polyethylene is suitable for hot water supply. Preferred for hot water will be PE80, and better PE100 or PE100 +.

- Gas HDPE pipes. Outwardly, they do not differ from products for water supply, but their side strips are painted not in blue, but in yellow.

- Technical PND pipes. An option not intended for the transport of any substances. These are very cheap products manufactured not according to GOST, but according to a separate manufacturer's specification. They serve to isolate the wiring.

How to choose HDPE pipes?

A very serious task is to choose a high-quality PND product. Unscrupulous manufacturers use in the process raw materials that are not of high quality. Even recycled plastic waste can be used.

Important! The service life of a low pressure polyethylene pipe will depend on the quality of the raw materials used in its manufacture.

Such pipes can be distinguished by the very pungent smell of plastic, emanating both from the new product and from the used one. The smell will not erode over time. Naturally, low-quality HDPE products are not suitable for drinking water. The shelf life of a product of poor quality will not exceed a few years, even if properly installed.

Also, the quality of the polymer can be determined by the color of the product. Fakes usually have a dirty gray or black color without any lettering or stripes. While a good non-pressure (and pressure too) polyethylene pipe, designed specifically for the supply of drinking water, will be painted blue.An option is black, but always with blue longitudinal stripes.

The walls of high-quality pipes should be smooth, to the touch or visually no foreign inclusions or clots of plastic should be detected. At the cut, the wall thickness should be the same, without hollows and protrusions.

Installation of polyethylene water pipes: preparation

The first thing that starts laying the water pipe from low-pressure polyethylene is the design of the circuit. It takes into account all water consumption devices (toilet, bathtub, shower, washing machine or dishwasher). Having prepared the scheme in advance, you will know how many pipes, valves, adapters and tees are needed to purchase.

The next step will be the preparation of the working area (dismantling the worn-out system, selecting the right tools). Before performing the installation directly, you must ensure that the water supply has been shut off. If replacement of the old water system performed in an apartment building, work must be agreed with the other residents of the entrance.

For the installation of water pipes, you will need a list of the following materials and tools:

- puncher - for drilling holes in the ceilings for the passage of the pipeline and fasteners under it;

- angle grinder (grinder) - if the dismantling of the old pipeline is required;

- construction scissors - are used for cutting measured lengths of pipes. It’s better to use scissors in the work, because when using a conventional hacksaw, too many burrs appear that need additional grinding.

- hammer, metal keys;

- fitting, a soldering iron for welding PND products are selected depending on the selected method of connecting the elements of the pipeline.

The main methods of installation of pipes made of low pressure polyethylene

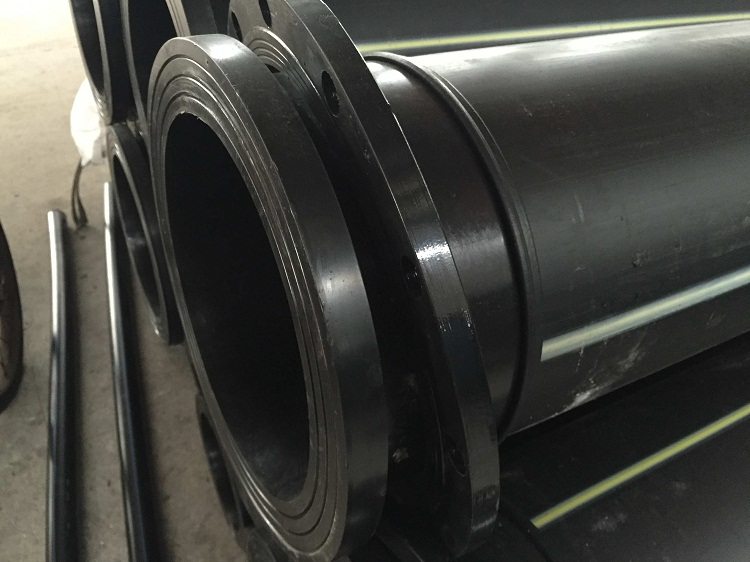

Installation of HDPE pipe for home water supply can be produced using compression fittings (crimp connections) electrofusion couplings or conventional butt welding. In rare cases, a flange connection is used. Each of these technologies has its advantages and disadvantages:

- compression fittings allow you to create a connection quickly and without the use of a welding machine. The most optimal choice for laying local water supplies. When using high-quality crimp rings and rubber seals, the joint will be sealed reliably. However, the connection will be collapsible - this means that at any time repair or replacement of sealing elements can be carried out;

- installation using welded couplings provides a stronger connection, which is necessary for gas lines or large-scale water supply systems;

- Butt welding is used for large highways and thick-walled pipes made of polyethylene (by welding, parts with a wall thickness of 4.5 mm or more can be connected). The butt welding process in the case of polymer products is very laborious. Since the softening of the material is very fast, the pipes must be in a fixed horizontal position. At the slightest distortion of the parts, a defective connection will be obtained, which will be unsuitable for operation.

Besides, welding installation requires careful observance of the temperature regime. If the junction was not overheated or, conversely, the heating temperature was not too low, its strength will be equal to the hardness of the whole pipe section. That is, the performance of the material will not decrease, as is the case with metal products.

Low pressure polyethylene pipes connected by metal flanges are usually designed for temporary use.Flange connections are quick, easy to disassemble. Items can be reused. If installation is carried out using additional flange parts, a soldering iron will be required to weld them to the pipe.

The flange connection is also applicable for the installation of HDPE pipes, in this case, first you need to weld the flange to the end

The most acceptable connection method for medium-sized (domestic) private water supply systems is installation using compression fittings. To obtain a reliable joint, wrenches are used. Before placing a piece of pipe into the fitting nut, it must be chamfered (45 degrees) from its end.

Connection using crimp fittings is also economical. In the event of a pipeline breakdown, only one failed segment can be replaced.

Installation of polyethylene pipes for water supply: tips

If you plan a hidden wiring of the pipeline in the walls, then the depth of the gate during punching is calculated by the diameter of not the pipes, but fittings. In the grooves of the strob the system must be fully recessed.

Important! Before closing the grooves with pipes in the walls with plaster, the system must be checked under the working pressure of water.

Also, when installing a water supply system at home, it is worth taking care of the presence of some elements of workwear. A work suit should be chosen so that you have the minimum number of open areas of the body. It will be more comfortable and safer to carry out installation in construction gloves. Dismantling work with a grinder and a perforator must be carried out in special glasses - this is a necessary measure to protect the eyes. When soldering parts, it is advisable to wear a respirator to limit the inhalation of vapors and smoke emanating from the melted polymer.

It is not always advisable to mount small diameter pipes by welding, it is better to use compression fittings

Installation must not be carried out near sources of heating or fire. Continuous heating negatively affects the strength of low-pressure polyethylene, designed to supply cold water.

To prevent deformation of the pipeline, fasteners should be placed at a distance of no less than 50 cm. Avoid too long sections in the system design. It is better if the horizontal segments are split using turning sections.

Pipes made of low pressure polyethylene are a great alternative to heavy metal structures. They can also be completely safely laid in the ground when conducting water supply to new buildings. Unlike steel structures, polymer products do not shrink in the ground, leading to premature system failures. Installation HDPE pipes does not present any special difficulties even for non-professionals.